|

Flying High With Electric Power!

The Ampeer ON-LINE!

Fly the Future - Fly Electric! |

Site Table of Contents

| President: | Vice-President: | Secretary/Treasurer: |

| Ken Myers | Richard Utkan | Rick Sawicki |

| 1911 Bradshaw Ct. | 240 Cabinet | 5089 Ledgewood Ct. W. |

| Walled Lake, MI 48390 | Milford, MI 48381 | Commerce Twp., MI 48382 |

| (248) 669-8124 | (248) 685-1705 | 248.685.7056 |

| ||

| Board of Directors: | Board of Directors: | Ampeer Editor |

| David Stacer | Jack Lemon | Ken Myers |

| 16575 Brookland Blvd. | 8908 Sandy Ridge Dr. | 1911 Bradshaw Ct. |

| Northville, MI 48167 | White Lake, MI 48386 | Walled Lake, MI 48390 |

| 248.924.2324 | 248.698.4683 | 248.669.8124 |

| Mailed Ampeer subscriptions are $15 a year US & Canada and $20 a year world wide. FREE on-line! | ||

| The Next Meeting: Date: Thursday, Dec. 6 Time: 7:30 p.m. Place Ken Myers's house, (see above for address) | ||

|

Ken Myers 1911 Bradshaw Ct. Walled Lake, MI 48390 Phone: 248-669-8124 Ampeer Paper Subscriber Reminder When subscribing to or renewing the paper version of the Ampeer, please make the check payable to Ken Myers. We do not have a DBA for the Ampeer or EFO. Thanks, Ken From Rich Flinchbaugh South Dennis, MA

Dear Ken, I have been looking forward to sending this note, for months.

It floats nicely on them with a total weight of 37 ounces. The weight per sq.ft. is a reasonable 14.4 oz./sq.ft. I am using a brushless outrunner ACn 16/25/4 Mega motor turning an APC 9x5 prop. The ESC is a Castle Creations Phoenix 35 and the receiver is the new, miniature Berg 4L.

With best wishes,

(Thanks Rich. You can send postal mail to Rich Flinchbaugh, 7 Avon Ln., South Dennis, MA 02660. KM) Cobra Takes to the Air

After weeks of frustration caused by weather and work I finally maidened the Cobra today! WOW! The airplane is everything Dan Santich said it would be in his Model Airplane News (MAN) write-up when he published the plans.

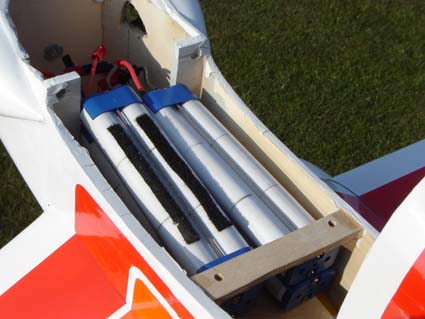

Mine came in at 19 lb. ready to fly! Power was a MegaMax 3.7 2Y on 12S2P A123s. Prop was an APC 16/10. The amp draw is about 52. All that power is handled by a Castle Creations HV85 electronic speed control (ESC). The radio was a Tracker III with an Airtronics receiver and JR Sport servos.

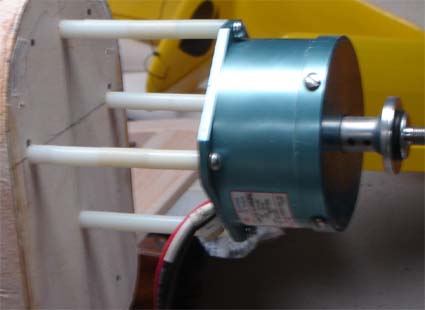

I made all the decals and lettering (except for the "N" number) on my ink-jet printer using both MicroMark and Testors decal paper.  Covering is UltraCoat; again, to save a little weight I made skins for the wing color scheme rather than just layering the UltraCoat.  The photo of the MegaMax shows the standoffs made from nylon spacers purchased at Ace. This is an early test-fit photo, before base washers at the firewall were added.

Walt  Sources:

November 2007 EFO Flying Meeting Saturday, November 3, 2007 turned out to be a great flying day for the EFO.  The weather was about as good as it ever gets here in Michigan in the first part of November. The temperatures started in the mid-40's and migrated to the mid-50's by afternoon. Until about 1:00, the winds were moderate and the turn out was very good.  Roger Wilfong had his new, scratch built from plans, 4 Star 40 ready for its maiden flight. It uses a geared cobalt Astro Flight 40 and 6 M1 (A123 Systems) cells.  The 4 Star can be seen on a landing approach after the very, very successful maiden.

Tom Bacsanyi's P-38 is always a pleasure to watch. The first photo shows the size of this beast and the second shows it on final.

Dave Stacer had a lot of fun with his QuickWing, especially the last flight of the day when he and Ken were flying in "quite a breeze." Where the heck did that come from?

The meeting will be on Thursday, December 6, 7:30 p.m. at Ken Myers's house. The address and his phone number are in the Ampeer header. Everyone is welcome. Bring your latest projects and gadgets to share. The 2007 Mid-Am Report The 2007 Mid-Am, once again took place on two hot days in July. It was well attended, and as usual a lot of fun with a lot of camaraderie, sharing, and flying.

All up/Last down - Jack Iafrat/Super Ava Most Beautiful - Doug Jablonski/Ford Fliver 3 Best Scale - Jim Young/WACO YMF Best Ducted Fan - Dave Grife/Vampire Best Sport Plane - John Lewis/E-Venture CD's Choice - Don Belfort/Quickee Sunday's Awards

Because of the extreme heat on Sunday, the flying stopped about 1:00, with the awards presentation and the announcement that the Midwest RC Society, host club field, had lost the use of the 5 Mile Rd. Flying Field. As of this writing, the 2008 Mid-Am plans are on "hold."

Some of the folks who flew with us in the "early" days! L to R: Dick Flemming, Don Belfort, Jim Young, Martin Irvine, Phil Alverez, Keith Shaw, Ken Myers, Dave Grife, Plenny Bates

Some EasyStar Upgrades

Fred found some changes he wanted to make to the Multiplex EasyStar, and he wanted to share these changes with the Ampeer readers. I am still flying the stock RTF version except that I now use 2 M1 (A123 Systems) 2300mAh cells instead of the supplied 6-cell 600mAh NiCad.

Ken,

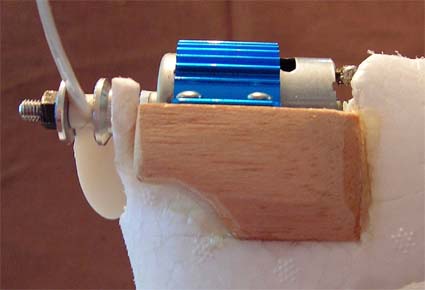

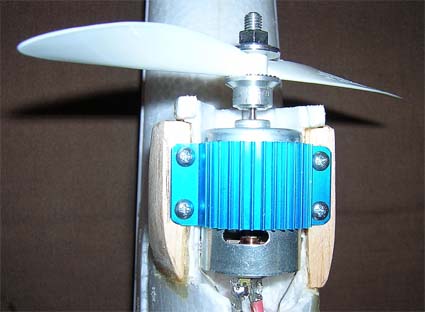

I rarely build anything strictly stock. The following changes added less than one ounce to the overall weight, which does not affect the super flying quality of the EasyStar, but I think they will add to its longevity.  1. Multiplex cautions to let the motor cool down between flights. No wonder, it is encased in foam to keep it hot! I cut the top half of the motor capsule off, kept the angle of the motor the same but added two hard balsa pieces. I used half of a motor clamp with cooling fins screwed to the balsa to hold the motor down. I put double stick tape around the motor before clamping in place. This prevents the motor from sliding forward and the prop striking the foam body.  2. Multiplex has the two motor wires embedded in the foam inside the fuselage, but after gluing the sides together you would never be able to move them. I didn't want connectors at the motor, so I soldered the wires to the motor and ran two small plastic tubes from just in front of the motor up to the cockpit. Now I can take the motor out and pull the wires back to solder them to another motor. 3. Multiplex had the prop glued to the motor shaft. I used a collet type prop adapter from Maxx Products to hold the prop. I had to ram the prop by about 0.015 to make it fit the adapter. (The prop adapter can be seen in the motor mount photos. KM) 4. Multiplex supplied a white plastic tube to go on the bottom of the fuselage for the antenna wire. This still left the antenna exposed where it exits the fuselage and right where the plane lands. I ran the same small plastic tube from the cockpit to the tail for the antenna to be inside the fuselage. 5. The foam fuselage, from behind the motor to the rudder, seemed flimsy. I added a 1/4-inch diameter dowel from the motor area to the tail. I embedded this in the center of the fuselage before I glued the two sides together.  6. I keep all of my planes rigged so that I donŐt have to reverse servos. To do this, I moved the elevator control horn to the top of the elevator. I added a thin piece of plywood on the bottom of the elevator and used #4 sheet metal screws through the control horn and into the plywood. I used the same anchor system on the rudder control horn. 7. The foam hinges for the elevator and rudder seemed weak to me. I used 2-inch wide clear packing tape over the hinges to make them stronger. Use a Popsicle stick to force the tape down into the joints. Sand the mold bumps to make the control surface smooth so the tape will stick.

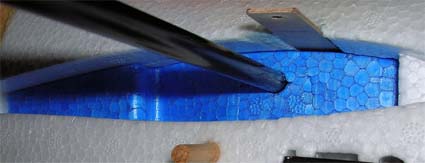

8. I was concerned about the wing becoming loose in the slot in the fuselage after time. I glued a 1/2-inch wide by 4-inch long piece of thin plywood to the top of the slot for the wing and used two sheet metal screws into the wing to keep it in place. The picture shows an embedded (glued) 1/4" diameter birch dowel to hold the screws. The dowels split in the first hard landing. I replaced them with 1/8-inch by 3/4-inch by 3/4-inch plywood plates for the screws.  9. I didn't like the idea of gluing the servos into the pockets. I made two 3/32-inch plywood "U" shaped plates and epoxied them into the servo pockets so that I could use servo-mounting screws. It is a solid mount and will make changing servos easy, if I ever need to. 10. I have had trouble keeping the battery packs in place. My fix was to cut a 2 1/4-inch front to back and full body width hatch in front of the cockpit to create a pocket to contain the pack. I put a foam wall between the battery compartment with enough space for the wires to slip under the foam and into the cockpit. It is deep enough to keep the pack in the compartment. 11. To allow novices to fly the EasyStar easily, it has great stability. Unfortunately I think that they over did it on the rudder. I added a piece of 3/32-inch thick by 1/2-inch wide balsa to the trailing edge of the rudder. I put clear tape over the joint and painted the addition with whiteout. The Elapor foam appears strong but has a surface coating. Multiplex says not to use epoxy, but I think that by removing the outer skin and putting holes into the foam, that will allow the epoxy to hold. I used epoxy on the motor mount and the control horns. Time will tell if I was right. An Electric Ducted Fan (EDF) Test Rig

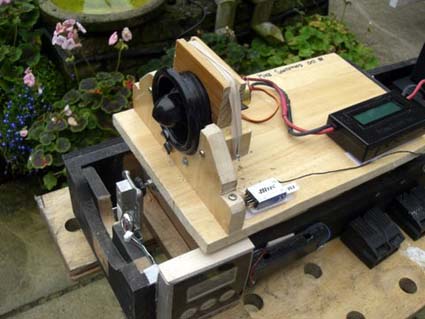

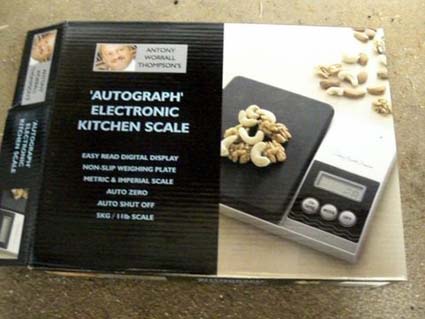

Michael has written up several articles for the Ampeer. His most recent was the "KATANA MD: Advanced Freestyle EP Model Review" in the September 2007 issue. KM Ken, You might be interested in my homemade test stand for Electric Ducted fans. It uses a chopped up set of digital scales. The top board floats on vertical hinged pillars so that it pushes on one end of a load cell removed from the scales. I have various fixtures, which allow me to fit almost any EDF and check the thrust, amps, watts and volts.

The Box the Scale Came In Three Different Systems Being Tested

I use an Astro Flight Inc in line power meter (Whattmeter), a spare Hitec receiver and an old Jeti 40 amp ESC. The power is provided by a 2200mAh 20C Li-Poly. Thrust is shown on the digital readout either in pounds or grams.

Regards,

And In a Follow-up Email

Mike Southwood

Upcoming Event of Interest: Skymasters R/C of Michigan would like to welcome your club to join us for: Spread "Spektrum" Featuring a discussion with John Adams the Technical Director Spektrum at Horizon Hobby. Come learn everything you wanted to know about: Spread Spectrum Technology with a Presentation, Hands On, and Q&A. The Location is Larson Middle School, 2222 E. Long Lake (18 Mile), Troy, MI 48085 Free Admission! All Welcome!!! It is sure to be an interesting evening!

From Gordy Stahl GordySoar@aol.com

This was sold, but the buyer ran into some bad luck, so its back on the runway: Includes Extra motor/gearbox/batteries/props also, all brand new.

|

To Reach Ken Myers, you can land mail to the address at the top of the page. My E-mail

address is:

KMyersEFO@theampeer.org

EFO WEBsite