|

Ampeer Paper Subscriber Reminder

When subscribing to or renewing the paper version of the Ampeer, please make the check payable to Ken Myers. We do not have a DBA for the Ampeer or EFO. Thanks, Ken

RCadvisor's New EZ Optimizer

From Carlos Reyes carlos@rcadvisor.com

I've been busy!

I completely overhauled the tutorials. No screen was left untouched. The biggest new addition is a detailed step-by-step example of optimizing a power system. This tutorial is almost as long as all the other tutorials combined, and it doubled the size of the tutorial flash file to 2MB. My goal was to answer every question that might come up during the optimization process. Check it out and let me know what you think.

All the work on the tutorials really helped me step back and think about how the Power System Optimizer is typically used. The result is a brand new feature, the EZ Optimizer, which dramatically simplifies the process of optimizing a power system. There are only two questions to answer: maximum propeller diameter and maximum number of series battery cells. Every other input to the optimizer is completely automated but still fully customizable.

There are several other new features, too many to list all of them here. An exciting new feature is the ability to compare two components side-by-side in a single graph. Not sure which of two motors to buy? Compare them on the same graph. The differences can be very dramatic. While writing the tutorials, it became obvious that more complex scenarios required an "or" capability between filter conditions. Done. You can now have multiple motors within the same power system. This is fully supported by the optimizers. To make it easy to work with another website member, I added the ability to load another user's components (this is easier to do than to explain). In the process, I added the account names to the component names (i.e., "Sig Kadet Senior [mike]"). It is now much easier to find a component. The database has grown to 6,395 components with 4,112 of those preloaded by me. There are now 1,236 model airplanes and 1,383 motors.

Do you run a website? The calculator is now an easily installable web widget. Grab it and put it on one of your web pages at no charge. If you sell R/C products, I'd be happy to put together a custom component database just for you.

Wanna know more about me and the calculator? Listen to my interview by the guys over at All Things That Fly (allthingsthatfly.com). I've gotten a lot of compliments on this one.

Design Contest Update

Just hours after the model airplane design contest announcement, we got our first entry. And it's a good one! But c'mon folks. With almost 2,000 registered members, I know there are a lot of other great designs out there. You've got through the end of October to enter your design. For more information, go to the forum.

To sweeten the pot, I'm adding a bunch of stuff to the prize. The complete list is now:

* Blue Wonder outrunner 1700Kv, 24gr

* Speed control 10amp, 9gr

* LiPo battery pack 500mAh 2S1P, 20C, 34gr

* Micro servos 11 inch-oz, 5gr (2x)

* 1-year subscription to RCadvisor.com

* #1 aluminum Knife Handle with #11 blade

* Excel #11 blades (100x)

* Excel Retractable Utility Knife

* Slow Flyer 8x3.8 propeller

* Extra motor shaft

* Radial motor mount

* Prop saver

* 2mm gold connectors for motor (3x pairs)

* Deans connectors for battery (1 pair)

* Nitrile disposable gloves, large (100x)

* 28 compartment organizer

* Stainless steel shop scissors

* #1 comfort-grip knife handle, 5x #11 blades

* Single edge razor blades (100x)

* Disposable epoxy brushes (36x)

* Free shipping (at least $15 value)

This brings the retail value to over $175. If you prefer cash, you can now hope to score $75. To be honest, I paid more than $75 for the stuff. But if you'd really prefer the cash, that's fine.

Vote in the contest! All it takes is about a minute of your time. If you have more to say, please feel free to add a comment to the corresponding airplane design thread.

Carlos Reyes

RCadvisor.com

Founder Brainy calculator

Return to "What's In This Issue"

Converting a Lou Andrews Aeromaster Biplane to Electric Power

By Ken Myers

Recently I received a request from my flying buddy, Rich Severt, of the Midwest club. He wanted to know what it would take to covert his Aeromaster from a 4-stroke glow powered version to an electrically powered version.

This plane was one of the very best flying sport biplanes of all time. It is a classic It is still available as plans from the AMA. ( href="http://www.modelaircraft.org/plans/pdfs/a-plans.pdf" target=_blank>www.modelaircraft.org/plans/pdfs/a-plans.pdf)

There are various iterations of this plane with varying wing areas and wing plan-forms.

Below is a photo of an early version using rubber bands to hold the wings on. The photo is from a thread at RC Universe. It is not Rich's plane.

Here is the information that Rich supplied me with about his plane. KM

Hi Ken,

I built a nice [still is] Aeromaster in 1986 and was considering conversion to electric power with an "A123" battery system.

Here are the current specifications:

Weight: 8 lbs. 8 oz. ready to fly less fuel

Wing Area: 892.5 sq.in.

Wing Span: 52.5 in. (both wings swept)

Current Engine: 82 Saito 4-stroke at 462g

Radio Battery: 700ma NiCad

Tank: 12 oz.

Servos: Five 9202 Futaba

If you have a chance, please give me your thoughts on conversion with recommendations on motor size and type, battery configuration, ESC, and any other hints and tips.

Thanks for your help. My Super Sportster with the Scorpion 3020-12 and "A123" batteries flies great.

I'm using the TME Xtrema charger as you suggested. (www.tmenet.com/xtrema.htm)

I was using a 13x8 prop with the Saito .82. I might get by with a 14-inch prop if necessary.

Thanks,

Rich

The first thing I did was to see how the plane compares to others of its type on a flyability and performance level. It has a cubic wing loading (CWL) of 8.8 oz./cu.ft. empty or 9.51 oz./cu.ft. fueled. That means that the flyability is typical for a sport plane. For an explanation of CWL, see www.theampeer.org/M1-outrunners/M1-outrunners.htm#CWL

Next I looked at its performance factor (PF), which takes into account the pitch speed and thrust. I used the Internet to guesstimate the RPM of the Saito .82 4-stroke with a 13x8 prop and decided that 9700 RPM was a reasonable guess, give or take a couple of hundred RPM either way. I have data for 50 other glow and gas planes with typical sport plane CWLs. The average PF for the 50 planes is 17.69 and median is 17.01. This version has a PF of 17.76.

Based on 9700 RPM using the 13x8, it has a pitch speed of about 73.5 mph and stall speed of about 17.3 mph yielding a pitch to stall speed ratio of about 4.24 to 1. That is very nice, as anything above a 4:1 ratio is excellent. I estimated the thrust for the 13x8 at 9700 RPM at about 128.33 oz., which gives it about 0.87 to 1 power to weight ratio with a full tank of fuel.

I then considered the limitations:

1. No larger than 14-inch diameter prop

2. No more than 10 "A123" cells (charger limitation)

3. Weight of the plane minus the engine, tank and throttle servo - about 116 oz. (that's minus about 20 oz.)

Using Drive Calculator (www.drivecalc.de) and my spreadsheet I looked at 6 possible power systems.

Conversion 1:

Motor: Scorpion S-4025-16, 10S1P "A123", Castle Creations (CC) Phoenix HV-45, APC 14x10E

RTF weight: 161.2 oz.

CWL: 10.5 oz./cu.ft. (typically advanced sport)

Pitch Speed: ~78.6 mph Stall speed: ~18.9 mph

Pitch to Stall speed ratio: 4.17

PF: 14.25 (Average for Advanced Sport electrics 9.06, median 7.54) but still less than the glow 4-stroke

Watts in per pound: 99 (good)

Thrust to weight ratio: 0.72:1

Conversion 2:

Motor: Scorpion S-4020-16, 9S1P "A123", Castle Creations (CC) Phoenix HV-45, APC 13x8E

RTF weight: 156.3 oz.

CWL: 10.1 oz./cu.ft. (typically advanced sport)

Pitch Speed: ~71.2 mph Stall speed: ~18.6 mph

Pitch to Stall speed ratio: 3.83 (still very good)

PF: 11.85 (Average for Advanced Sport electrics 9.06, median 7.54)

Watts in per pound: 92 (not too bad)

Thrust to weight ratio: 0.88:1

Conversion 3:

Motor: AXI 4130-20, 10S1P "A123", Castle Creations (CC) Phoenix HV-45, APC 15x10 pattern

RTF weight: 163 oz.

CWL: 10.6 oz./cu.ft. (typically advanced sport)

Pitch Speed: ~70.5 mph Stall speed: ~19 mph

Pitch to Stall speed ratio: 3.72 (still very good)

PF: 11.90 (Average for Advanced Sport electrics 9.06, median 7.54)

Watts in per pound: 100.8 (good)

Thrust to weight ratio: 0.85:1

Conversion 4:

Motor: Scorpion S-4020-16, 10S1P "A123", Castle Creations (CC) Phoenix HV-45, APC 13x7 sport

RTF weight: 159.2 oz.

CWL: 10.3 oz./cu.ft. (typically advanced sport)

Pitch Speed: ~68.9 mph Stall speed: ~18.75 mph

Pitch to Stall speed ratio: 3.68 (still very good)

PF: 13.12 (Average for Advanced Sport electrics 9.06, median 7.54)

Watts in per pound: 100.4 (good)

Thrust to weight ratio: 0.90:1

I did the "best" two conversions using a 8S1P 2500mAh Li-Po battery for comparison, as the flight times would be approximately the same.

Conversion 1a: Li-Po

Motor: Scorpion S-4025-16, 8S1P 2500mAh Li-Po, Castle Creations (CC) Phoenix HV-45, APC 14x10E

RTF weight: 151.6 oz.

CWL: 9.83 oz./cu.ft. (typically sport)

Pitch Speed: ~78.6 mph Stall speed: ~18.3 mph

Pitch to Stall speed ratio: 4.30

PF: 16.11 (Average for Sport electrics 13.46, median 13.35)

Watts in per pound: 105 (good)

Thrust to weight ratio: 0.76:1

Conversion 4a: Li-Po

Motor: Scorpion S-4020-16, 8S1P 2500mAh Li-Po, Castle Creations (CC) Phoenix HV-45, APC 13x7 sport

RTF weight: 149.6 oz.

CWL: 9.7 oz./cu.ft. (typically sport)

Pitch Speed: ~68.9 mph Stall speed: ~18.2 mph

Pitch to Stall speed ratio: 3.79 (still very good)

PF: 14.85 (Average for Sport 13.46, median 13.35)

Watts in per pound: 110.7 (good)

Thrust to weight ratio: 0.96:1

This version of this plane is really optimized for the glow 4-stoke. Whether or not it is worth the cost of conversion is hard to say. If I had to choose a version, I would choose Conversion 4. It would cost between $125 and maybe $150 dollars for a 10-cell "A123" pack, a Castle Creations Phoenix HV-45 would run about $130 plus shipping and the Scorpion S-4020-16 about $85 - $90 plus shipping. $300.00 plus is a lot of money to spend, as it is not really a great candidate for conversion.

There would also be a cost of time in fitting the conversion and possibly redoing parts of the beautifully finished airframe to accommodate the conversion.

That is not to say that this airframe, built and covered from scratch, as an electrically powered plane wouldn't be as good or better than this glow version. The airframe itself is not overly heavy, and built with a few design changes, it could become a great flying, electrically powered biplane.

Return to "What's In This Issue"

Bob Livin's Super Quaker with "A123" Cells

From Plenny Bates plennyb@mchsi.com

Ken,

The photo is of Bob Livin's Super Quaker. It was taken near Chamberlain SD on a day when the wind quit so there was no slope soaring.

Details:

Designer: Matt Kania

Builder: Bob Livin

Designed in 1941 or 1946 (Depends on where you look). My guess was '41 and then after the war it may have been kitted or published.

Wing Span: 75 inches

Wing Area: 795 sq.in.

Weight: 83 oz. (5.19 lb.)

Motor: Astro Flight 40 geared 1.68:1

ESC: Castle Creations

Battery: 6S1P "A123"

Watts in: 590 (114W per pound)

CWL: 6.4 oz./cu.ft. (typically "park flyer")

Wing Loading: 15 oz./sq.ft.

This winter we are building 4 Sig Ninja slopers from plans. We have cut the blue foam and Bob has made two fuselages and has the parts cut for the last two. No cutouts in the fuselages and 0.007" carbon stiffeners. Controls are elevator and ailerons (2 servos in wing). Using two permits camber control but more importantly lets us use spoilerons for glide path control. Will use Multiplex cans to hold the wing servos so they can be changed out with ease. All servos will be HS-85 MG. Over the wing foam will be 0.003" carbon darts, 0.75 oz glass to carry epoxy (will get as dry as can with a scraper) and veneer (0.015" paper bonded to 0.008" wood). I am getting the vacuum system stuff. We have a Welsh 1400 pump (quality pump, cost new $1890.00) which I picked up for $80.00 and will have an Airtrol spring biased comparator to control the bag pressure. The pump will run continuously pulling 30" Hg of vacuum but the controller will hold the bag vacuum at 4"Hg (2PSI) or what ever the setting. This keeps the pressure very constant and lets the epoxy set without being "worked" by pressure variations. We are working on a very flat bench (+ - 0.003") so our wings should be straight.

Enough from the land of corn.

Plenny Bates

Return to "What's In This Issue"

More on Keith Shaw's Bearcat

From Keith Shaw Ann Arbor, MI

Keith Shaw's Bearcat in 1996!

Exactly what is the power system setup in the Bearcat in 2008? KM

The Bearcat still has the MAT (ModelAir-Tech) belt drive (3:1 IIRC) driving the 22x16 prop, but now has an Astro 60 brushless (4 turn) with a Castle Creations 85 HV controller, fed by 10S2P pack of 2300mAh "A123" cells. Batches of two cells are soldered together in parallel, and then those are connected in series using braid soldered to the tabs. The cells were all "retrieved" from DEWALT 36V packs. Battery taps are added for my FMA CellPro 10s charger. Total weight of the plane dropped from 15 lb. to just under 14 lb. This is quite light for a 1/5.5 scale Bearcat with a span of 81", area around 1150, and main and tail wheel retracts.

The old power system (32 x 1700SCRC Ni-cads, Astro brushed FAI 60) pulled 45 amps and turned the prop at 4.4K. This gave a good aerobatic envelope for a 4-minute air show routine, although sometimes I could not taxi back if there was a lot of wind, as those situations require higher power levels through maneuvers. Motor and cells were too hot to touch after a flight.

The new system turns the same prop at 4.9K, which gives me MUCH better vertical, easy vertical 4-point rolls and vertical square eights, while the original system could just do a clean vertical roll and struggled with a vertical eight on hot days. I can now do virtually the same routine, as my Zlin or Stomo, even though not very "scale" for a WW2 fighter.

The batteries and controller are at ambient temperature and the motor just warm after a flight.

But the BEST feature is that I now get to enjoy a solid, 10-minute, no-holds-barred aerobatic flight, with power to taxi back. I usually go through 4.0 Amp-hr of the 4.5 Amp-hr capacity. And I can recharge the Bearcat at the field with my own homemade charger. It is a highly modified Astro 112 PK Ni-cad charger. I just plug it into the jack on the side of the plane, and in 40 minutes it is ready to rock n' roll again. I do use the FMA charger at home, as I find a balanced charge about every ten flights keeps the "A123s" in sync.

With Ni-cad power I thoroughly enjoyed flying the Bearcat, but always wished for more. The short flight and long cool-down time would never allow a second flight in the time I had at the flying field. It was a lot of work to take it to the field for one 4-minute flight, so I only flew it at air shows demos. Now I can get three flights in, and enjoy other planes as well in the time I have.

I light candles to the A123 gods ever day to express my thanks for a safe, rugged, reliable cell to re-power/improve my fleet of aging Ni-cad-powered planes.

With the help of W's $600 assistance, my Spitfire Mk 1a (6 cells), Zlin 526 (6S), Coulombia (4S), Flashback bipe (4S), Gee Bee R-1 (4S), Goon (14S!), Crosby CR-4 (8S), Moeller Stomo (8S), and Bearcat (10S2P) now fly with "A123" 2300mAh Lithium Iron Phosphate cells. If/when the Li-pos in the Bugatti, Bucker Jungmann, or CzechMate fade, they will be converted to "A123s". I am hoping to convert my Stearman (10S), and re-power my DeHavilland Comet with new motors and a 4S2P pack this winter. Even my big 1/4 scale Fokker D-8 is under consideration, but I will have to figure out how to make a conformal pack to fit under the cowl to get it to balance!

That's probably more than you wanted, but I've been meaning to send you an update on all my projects.

Keith

Return to "What's In This Issue"

Power Question

From Arden McConnell

Ken,

What data do I need to collect to determine the power output of an Eflight system?

I can measure the power input (Volts, Current), motor RPM, propeller info and the thrust of the plane with the motor running but is this enough? If this is all I need, what do I do with it?

Thanks for any help.

Arden McConnell

Ken's response:

To measure the output power of any motor or engine you need a dynamometer. These are NOT easy to construct. The ones built for our purposes, which are hard to come by, are extremely expensive.

The output from the motor generally runs between 65% of the input power for the smaller diameter motors to 75% of the input power for medium to large diameter motors. Some are slightly better, most are worse, especially the cheaper ones.

If you are flying 3D type planes or helicopters, you might be interested in a static a thrust measurement, but for planes the "fly on the wing", it is not all that helpful.

The pitch speed to stall speed ratio is an indicator of how well a plane will fly.

The pitch speed, in mph, is calculated using the RPM times the prop diameter in inches divided by 1056.

Example: a 10x8 prop at 8600 RPM yields a pitch speed in mph of 8 (pitch) times 8600 (RPM) = 68800 divided by 1056 = 65.2 mph

Most of our planes are not clean enough to reach the theoretical pitch speed, but it is a useful number.

The stall speed in mph is about 3.7 times the square root of the wing loading.

Example: Wing loading 15 oz./sq.ft. The square root of 15 = 3.873 times the constant 3.7 = 14.3 mph

The pitch speed to stall speed ratio is the important element when determining how well a plane will fly "on the wing."

Generally a plane can do loops from level flight, etc. with a pitch speed to stall speed ratio of about 2.

A plane with a pitch speed to stall speed ratio of 3 is very aerobatic.

A plane with a pitch speed to stall speed ratio of 4 has fighter like performance.

I like to have my planes fly in the 3:1 to 4:1 range.

In the example above, the pitch speed to stall speed ratio is 67.4 mph divided by 14.3 mph or about 4.55 to 1 (4.55:1) - It would be an excellent flier

To get back to your original question, you don't really need to know the output power, and there is a free motor calculation program that will give a reasonable estimate. The program is called Drive Calculator and can be found at www.drivecalc.de

Another indicator of performance is the watts in per pound of weight. For my sport and sport scale planes I try for about 100 watts in per pound to 125 watts in per pound. 3D flyers generally use a minimum of 150 watts in per pound and really get their kicks from 200+ watts in per pound

If you are flying 3D planes, then prop with the largest diameter and lowest pitch prop you can swing on the plane for ground clearance and put between 150 watts in per pound to 200 watts in per pound and it should do whatever you can do.

Return to "What's In This Issue"

Lots of Indoor Info!

Skymasters R/C Club

In conjunction with Romeo Skyhawks

Ultimate Soccer Arenas, Pontiac, MI

Winter Indoor Flying!

Tuesdays thru the Winter

Started November 11, 2008,

But not to late to join in the fun!

Ultimate Soccer Arenas

867 South Blvd, Pontiac, MI

(west of Opdyke on the north side of South Blvd)

Flying area is 365 ft by 260 ft with 45 ft to 75 foot ceilings!

Come join us for some indoor fun!!

R/C Flying Schedule: Tuesday 11am - 1pm

Ample space for concurrent flying of 3D, Heli, Sport Flying!

Temperature controlled, well lit.

Restaurant on site.

for event status throughout the winter.

Five Sessions for $25

Pilots must show proof of AMA membership

Ultimate Soccer Arenas - ultimatesoccerarenas.com

For more information call Joe Hass 248-321-7934

Visit the Skymasters' website at www.skymasters.org

Easily the largest facility of its type in the country, Ultimate Soccer Arenas house two full size regulation soccer fields, plus a third practice field all in a single building. This is not an inflatable dome, but rather a conventional structure with indirect lighting and temperature control. Each field is connected with a beautiful atrium. There is also a mezzanine for viewing activity from above. Each full size field measures 330 feet by 260 feet. At the highest point the ceiling is 75 feet.

Jason Cole, Advertising and PR Director for Hobby Lobby International received a tour of the arena during his visit to the Skymasters on October 29. Jason said "This is larger that the JR Fest and E Fest".

During the introductory session over 50 pilots and guests were in attendance. Ten pilots routinely flew simultaneously. Bleachers made seating and aircraft set up easy. The facility includes a coffee shop, restaurant and bar. Regular flying will begin on Tuesday November 11 from 11 AM until 2 PM.

And more from Joe Hass, President Skymasters

We will have indoor flying at Ultimate Soccer Arenas on Saturday, November 29 (Thanksgiving Saturday) from 11 AM to 3 PM. Cost will be $20.00. Anyone who purchased the "Gold Card" for the Tuesday sessions will get a $10.00 discount.

There is a bar, fantastic restaurant, large screen displays for watching football and video game room for kids that are not flying. Shopping for the wife/mom is as near as Oakland Mall or Great Lakes Crossing.

We had 36 pilots, about 60 people total last Tuesday for the kick off. The owners gave us an extra hour. The restaurant was full afterward.

Nothing like it anywhere.

The following information came via email from the Ann Arbor Falcons. KM

Saline Community Education Presents

Indoor Flying

RC Indoor Flying in Saline, Michigan

RC Electric Indoor Flying Dates: November 14, 21, 28, December 12, 19, 26, January 2, 9, 16, 23, 30, February 6, 20, 27, March 6, 20

Friday Nights, 7:30 pm to 10:00 pm

Saline Middle School Gym

7190 N. Maple Rd

Saline, MI 48176

Cost: $10.00 per flyer

Coordinator: Phil Smith: 734-429-4707 (call if any questions)

E-mail: jphilipsmith@verizon.net

Directions: US-12 into Saline- Go north about 1+ mile on North Maple Rd., Saline Middle School is on the left.

KIEF Report

From Bob Aberle

Ken,

As you know the big JR Indoor Festival in Columbus, OH had to be cancelled because the dome collapsed in a windstorm last month. In its place most of us attended the new Keystone Indoor Electric Fly (KIEF) in Muncy, PA, near Williamsport. It turned out to be spectacular! The dome is the largest inflatable sports dome in the USA (600 feet long!). I prepared an extensive report for posting to John worth's RC MICRO WORLD to help promote his webzine. We have made my report accessible on a FREE website. We are asking all editors and columnists to spread the word. KIEF will likely become the NEAT Fair of the indoor world.

I hope you like this report. Something this extensive could only be posted on a webzine!

The Keystone Indoor Electric Fly Report by Bob Aberle appears in the November 2008 issue of RC MICRO WORLD. The FREE access is: www.cloud9rc.com/kief

After opening click on the "PRINTABLE VERSION" box at the top, right of the article. Then the pages will scroll continuously without a break

Bob A.

Turn-Around Preview

From Bob Aberle

Ken,

Attached is a photo of this week's project. I call it the TURN-AROUND. It is an indoor electric flyer with ailerons instead of rudder control. It is all balsa with a Jedelsky wing section, but the wing bottom is covered. Wing area is 100 square inches, total weight just 4.2 ounces. Motor is an E-Flite PARK-180 running 15 watts input power on a two cell 250 mAh Li-Poly pack. It should be published with downloadable plans in the December of January RC MICRO WORLD.

The plane can be built in a days time. There are no real wing ribs to cut out. Best of all it uses all off the shelf relatively inexpensive RC equipment.

Bob A.

Return to "What's In This Issue"

Increasing a Hangar 9 Sopwith Camel's Flight Time

Question from Jim Cross, EFO member

From Jim; I'm still working with Bill Brown to improve the flight time of his Hangar 9 Sopwith Camel. It has 5 M1 cells, his AXI 4120-1? and an APC-E 14x7.

From our bench tests, we estimated flight time of about 7 minutes (figuring 30 seconds at WOT, 7500 RPM, ~41 Amps for takeoff and then at ? throttle, 5700 RPM, 7.25 Amps for the remainder of the flight.

But recent flight tests revealed that the plane needs to fly at about ? throttle to "keep the nose up"; at that setting, he only has about 3 minutes of flight before the M1 cells are drained. Bill's talking about getting another motor, but I think that may be only half the battle; we'll probably have to add another 5 M1 cells in parallel to gain any significant flight time.

It looks like Bill's motor is an AXI 4120/14 from the data. I am not sure how you got the 7.25 amps for the remainder of the flight at 5700 RPM.

Your watts in calculate to about 530 static, 13.0v * 41 amps. Since, for simple purposes, the way a speed control works is by turning on and off the power like a light switch, not restricting the flow like a water valve, the ratio is controlled by time. Static full power is 530 watts in per minute. The usable capacity of a 2.3Ah "A123" cell is about 2.0Ah. 2.0Ah times 60 minutes is 120 amp minutes. 120 amp minutes divided by 41 amps = 2.93 minutes. If the motor were held at full throttle on the ground (of course you know not to do this), the pack would be drained in 2.93 minutes/175.6 seconds. 30 seconds of full power would use up 41 amps * 0.5 minutes (30 seconds) or 20.5 amp minutes. That would leave 99.5 amp minutes in the pack. 99.5 amp minutes divided by 2.5 minutes (the remainder of a 3 minute flight) would give an average amp draw of 39.8 amps.

I believe the 3-minute flight time to be inaccurate. It doesn't seem right that Bill is only getting 3 minutes before the cells are drained. 120 amp minutes divided by 3 minutes is 40 amps, which is just about the full throttle static amp draw.

Since the prop usually "unloads" some in the air, using the static numbers below is not exactly "correct", but can be used for comparative purposes.

Half power (265 watts in per minute), for this motor, battery, prop combination, gives an RPM of about 6050 and an average amp draw of about 26.5 amps. (Source, Drive Calculator) 99.5 amp minutes (remaining amp minutes in pack after 30 seconds of full throttle usage) divided by 26.5 amps = 3.75 minutes or 225 seconds. 225 seconds plus the 30 seconds of full power equals 255 seconds or 4.25 minutes of flight time. 4.25 minutes gives an average of 28.2 amps for the entire flight.

Two-thirds power (353.3 watts per minute) yields an average amp draw of 31.6 amps with an RPM of about 6635. Run time would 3.15 minutes or 188.9 seconds plus 30 seconds or 3.64 minutes. 3.64 minutes gives an average of 32.9 amps for the entire flight.

Three-fourths power (397.5 watts per minute) yields an average amp draw of 34 amps with an RPM of about 6890. Run time would 2.93/175.6 seconds plus 30 seconds or 3.4 minutes. 3.4 minutes gives an average of 35.3 amps for the entire flight.

Obviously no one flies at any one of the settings all of the time, but they are presented as comparisons.

To find the average flight amp draw for this plane, do an accurate timing of a flight, refill the pack noting the Ah returned to the pack and calculate the average amps. It will give you a good idea of the "average" throttle/power "position".

Paralleling the pack would not quite double the flight time. The amp draw would also go up due to less resistance in the battery. Even though the watts in would increase slightly, the watts in per pound would drop slightly because of the added weight of more cells.

If you are going to be using 10-cells, is there another, possibly "better", way to extend the flight time? (Obviously a rhetorical question.)

(All of the data from the Horizon Hobby Web site for the Camel and the Power 46 is noted with an asterisk.)

*Wing Area: 1288 sq.in. (26.75 cu.ft.)

*Flying Weight: 7.5-8.5 lb (120 oz. - 136 oz.)

Cubic Wing Loading (CWL): 7.5 lb. - 4.49 oz./cu.ft. to 8.5lb - 5.08 oz./cu.ft.

Bill's plane weighs 132 oz. The CWL for the Camel at 132 oz. is 4.93, which is a Level 3 plane from my database. The Excel spreadsheet

A power in recommendation is suggested by the choice of 2-stroke and 4-stroke engines by Horizon.

Evolution .61NT 2-stroke - equivalent watts = 0.61 cu.in. * 1500 (glow equivalent factor) = 915 watts

Saito FA-91 4-stroke - is about equivalent to a .61 2-stroke (0.91 * 0.66666667 = .607) but can swing a larger diameter prop. (2/3 is the typical 4-stroke to 2-stroke equivalent conversion factor)

Another way to determine the watts in required is to use watts per cubic foot for the CWL Level times the cu.ft. The CWL Level for this plane is a 3 (CWL 5.00 - 6.99). The average watts in for a Level 3 per cu.ft. is 42.56 and the median 37.19. The median watts in for this type plane would be 994.8 and the average watts in would be 1138.48.

It is important to note that the watts in per cubic foot will almost always be lower for a biplane as I have not segregated biplanes from monoplanes in my data.

A biplane has quite a bit of drag, which indicates that a large diameter, low pitch prop would be a good choice. It wouldn't hurt to target 100 watts in per pound.

1000 watts in indicates 10 "A123" cells in series using my 100 watts in per cell rule using 35 amps.

Bill is currently flying this plane with about 50% of this amount of power.

Horizon Hobby recommends the E-flite Power 46 outrunner with one 14.8V 6000mAh 4S3P or two 7.4V 4200mAh 2S2P Thunder Power Li-Po packs. The data for this motor/battery combination and a Castle Creations Phoenix 60-amp ESC from the Horizon Hobby Web site is:

*Option 1: Prop: APC 13x8E, Battery: Thunder Power PRO LITE 6000mAh 4S3P (THP60004S3PPL), Amps 51.5, Volts 14.4, Watts 745 (The math says 741.6), RPM 8250

It looks like Horizon Hobby is recommending using about 75% of the power that I have suggested. Horizon Hobby recommends this system for one reason only, economics. The motor and speed control for a 4S Li-Po pack is much less expensive than for an 8S Li-Po system, which is about equivalent to a 10S "A123" pack.

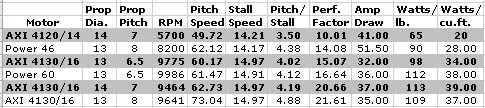

I did some extensive what-ifs and found two commonly available outrunners that work well with a 10S "A123" pack. The motors are the AXI 4130/16 (Kv 385 @ 409g) and the E-flite Power 60 Brushless Outrunner (Kv 400 @ 380g).

|