|

Flying High With Electric Power!

The Ampeer ON-LINE!

Fly the Future - Fly Electric! |

|---|

Site Table of Contents

| President: | Vice-President: | Secretary-Treasurer: |

| Ken Myers | Keith Shaw | Rick Sawicki |

| 1911 Bradshaw Ct. | 2756 Elmwood | 5089 Ledgewood Ct. W. |

| Commerce Twp., MI 48390 | Ann Arbor, MI 48104 | Commerce Twp., MI 48382 |

| (248) 669-8124 | (734) 973-6309 | (248) 685-7056 |

| ||

| Board of Directors: | Board of Directors: | Ampeer Editor |

| David Stacer | Arthur Deane | Ken Myers |

| PO Box 75313 | 21690 Bedford Dr. | 1911 Bradshaw Ct. |

| Salem, MI 48175 | Northville, MI 48167 | Commerce Twp., MI 48390 |

| (313) 318-3288 | (248) 348-2058 | (248) 669-8124 |

| Upcoming EFO Flying Meeting: January 11, 2023 Time: 7:30 p.m.

Place: ZOOM - URL will be posted here when known | ||

| EFO Meetings, Winter 2023 Winter meeting announcement. | Skymasters' Winter Indoor Flying in Pontiac, MI Indoor flying announcement. |

| Winter Indoor Flying at the Legacy Center in Brighton, MI Indoor flying announcement. | Model Aircraft Power System Data Collection and More: A Personal Account Ken Myers discusses how electric power system data collection and flying telemetry has changed over the decades. |

| Selecting Electric Power Systems Ken Myers helps Aaron select power systems for a PT-60 and Kadet. | Motor Naming Conventions Question Joe Hass asks what is the best way to name an electric motor and Keith Shaw and Ken Myers share their two cents worth. |

| One Way to Keep Your Thumbs Limber in a Michigan Winter An old friend shares a video of how he keeps his thumbs limber during a Michigan winter. | |

There will be no EFO monthly meeting in December of 2022 either in person or via ZOOM. The EFO meetings for January, February, and March will be ZOOM meetings. The reason for ZOOM meetings is the continued threat from COVID and now the severe outbreak of the common Flu in the more senior population. Also, I am really no longer capable of clearing the drive and street of snow and ice for safe walking to the house. I'll see you all via Zoom in January, Ken. Skymasters' Winter Indoor Flying in Pontiac, MI

Hi All, I'm very happy to announce that we have secured a spot at the UWMSC (UWM Sports Complex), 867 S Blvd E Pontiac, MI 48341, calendar for indoor flying. WE ARE BACK TO TUESDAYS FROM 9 AM - 12 PM! Registration for indoor is up for gold cards! Gold Cards, season passes, are $150 and single sessions $10. Thanks,

Winter Indoor Flying at the Legacy Center in Brighton, MI Indoor flying takes place from November 2rd, 2022 until April 26th, 2023 at the Legacy Center Sports Complex, 9299 Goble Dr., Brighton, MI, 48116 phone: 810-231-9288

The cost is $10 per drop-in session. Model Aircraft Power System Data Collection and More: A Personal Account By Ken Myers Early Data Collection Usage

In the late 1970s and early 1980s, it was common for AMA pattern planes to use tuned pipes on glow fueled 2-stroke model engines. An analog or optical tachometer was used to 'set the pipe length' for the engine and chosen propeller while the plane was on the ground.  The NorCal Avionic's tachometer, on the left, was also a receiver and transmitter pack voltage checker, voltmeter and ammeter. Both tachometers required natural or DC lighting for their readings. Neither unit could/can retain data. The Hobbico Digital Mini-Tach can be seen in action here. Tuning on the ground was followed by flight testing of the results. The propeller/engine/pipe combination would 'come onto the pipe' when the propeller unloaded in the air and the pipe had 'warmed up.' The tuning and flight testing was/is a tedious, repetitive process. Today, onboard, or telemetry, data collection could aid this process by taking RPM readings in the air and reporting pipe temperatures. In the early 1980s I entered the electric era. My first electric was a Midwest Sweet Stick with an Astro Flight, non-cobalt, 25 direct drive. A serendipitous meeting with Keith Shaw lead to a much greater involvement with electric power systems.

An Astro Flight Whattmeter, power meter, allowed me to check the electric motor and battery amps and volts under load. It could not record or log the data. For bench testing power systems, I used a video camera on a tripod to record the RPM, using an optical tachometer and the Whattmeter data. The simultaneous data could be written down by playing back the tape and pressing pause. In 1992, Bob Kopski, Model Aviation's electric flight columnist, was reporting on electronic data logging and capture for display on a computer. In the October 1993 Model Aviation, in his "Radio Control Electrics" column, Bob Kopski announced that Flightec (Phil Thayer) would produce a printed-circuit board for computerized data-collection.

The RC Data Logger used a serial adapter and program written in BASIC to view the data. Phil sent me a prototype unit. It had to be assembled. I never got it working correctly. I was still very interested in computerized bench and inflight data logging. In the November 1997 Ampeer I wrote, "I have a challenge for all of you "electronics" experts out there. Design a light-weight unit to go in a plane to measure RPM, Amps, and motor voltage, and store that data for download to a computer via a serial or parallel connection. Supply the computer software to display a graph(s) of that data through the whole flight, and do it for less than $200. Yes, I know it has been done, but the units I've read about are overly expensive for the "curious", average modeler to afford. How about it? Can it be done, be accurate, and be relatively inexpensive? km" In June of 2006 my optical tach/Whattmeter/video tape process was replaced with a Hyperion Emeter. It was able to save five data points that could be transferred to paper. In January of 2009 the Emeter was replaced by the much more capable Hyperion Emeter 2. The 2 has a remote data unit (RDU) that can be carried onboard to collect data. All data can be logged and then viewed on a computer. I continue to use the Emeter 2 to this day.

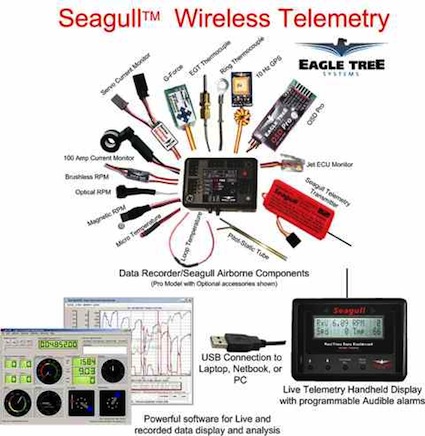

The original Emeter with the Emeter 2 During the 1990s, several more logging and telemetry units appeared on the market. Some of them logged the data in the aircraft and others used telemetry to send the data back to a 'receiver' unit. Seagull and Medusa were some of the earlier pioneers.  They also had a USB Flight Data Recorder for those not needing wireless telemetry. It was $170. It could be used to gather the following data; GPS positioning, RPM, temperature, air speed, amps, servo current, exhaust gas temperature, cylinder head temperature, and G-forces.  Medusa produced the Analyzer Pro and Oracle Data Recorder. They are no longer available. They also had the ability to record most of the data needed by RC pilots.  Until recently, and after 18 years, Eagle Tree Systems no longer produces the Seagull products and the eLogger V4, which was very similar to the Medusa Oracle.

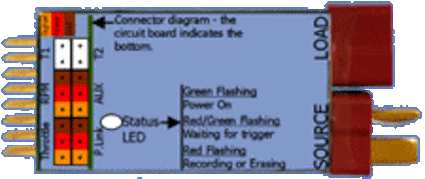

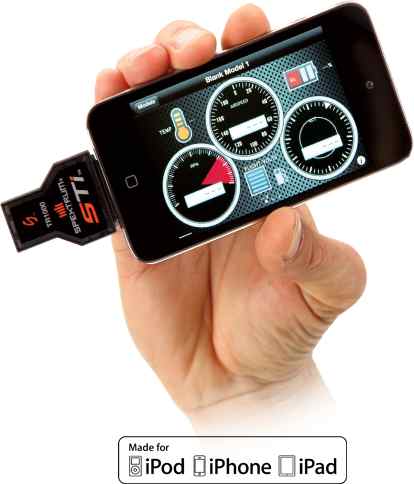

In the January 2007 Ampeer I reviewed the Jeti Spin 44 amp ESC and Spinbox. The ESC logged data; temperature, RPM, volts and amps. The data could be viewed on the Spinbox. Other means of viewing the data are now provided by Jeti. The Castle Creations Ice ESCs also have this capability. The ICE data can be viewed on a computer. Neither companies' ESC data collection is very accurate when compared to other data recorders! The advent of bi-directional 2.4GHz radio systems has allowed companies such as Spektrum, FrSky, Futaba and Hitec to provide real time data telemetry, at first, to some type of ground receiving unit.  Earlier data collection was sent to handheld devices.Both Spektrum and, previously, Hitec had the ability to display the recorded data on handheld device.

Spektrum Nitro data collection shown. Now the data is sent back to the transmitter and displayed on its large screen. While data collection is often associated with electric power systems, both gas and glow planes benefit from collected and real time data today returned to the transmitter.

High quality RC systems from Spektrum, Radio Master and FR Sky now feature voice call outs of real time parameters including altitude and battery level for both the onboard radio power and electric power systems. For ME, power system testing is still the most useful. Way back in 2012 I wrote the following. I demonstrates my power system testing at the time as well as pricing, 10 years ago.

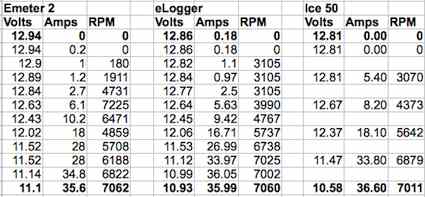

In the fall of 2012 I became much more interested in in-flight data collection. While my Emeter 2's RDU (remote data unit) can collect the data I want in the plane, I also wanted to try out another unit. For my inflight testing this year I was using the Eagle Tree Systems eLogger V4 with the Brushless RPM Sensor. I also purchased the PowerPanel LCD Display Expander to be able to use this system as a typical power meter. All three items were delivered to my door via Tower Hobbies for $85.97, including the free shipping. That is well below the $200 mark I was looking for in 1997. Most loggers/recorders are provided with software that presents data in a graphical and numeric manner. I prefer a numerical presentation in a spreadsheet. There is usually some way to open the 'captured' file in a spreadsheet. I compared the three logging methods that I was using at that time on a spreadsheet.  I used the data to determine which means I felt was more accurate, at that time. There is always a lot of misinformation, or poor advice, available on the Internet.  Horizon Hobby provided a video on YouTube in 2012 that was titled, "HorizonHobby.com How To - Using Spektrum Telemetry Part 1". It demonstrated how NOT to set up power system data logging on the ground. Whenever a power system is being worked on on the ground with the battery connected, the prop MUST be removed! Selecting Electric Power Systems

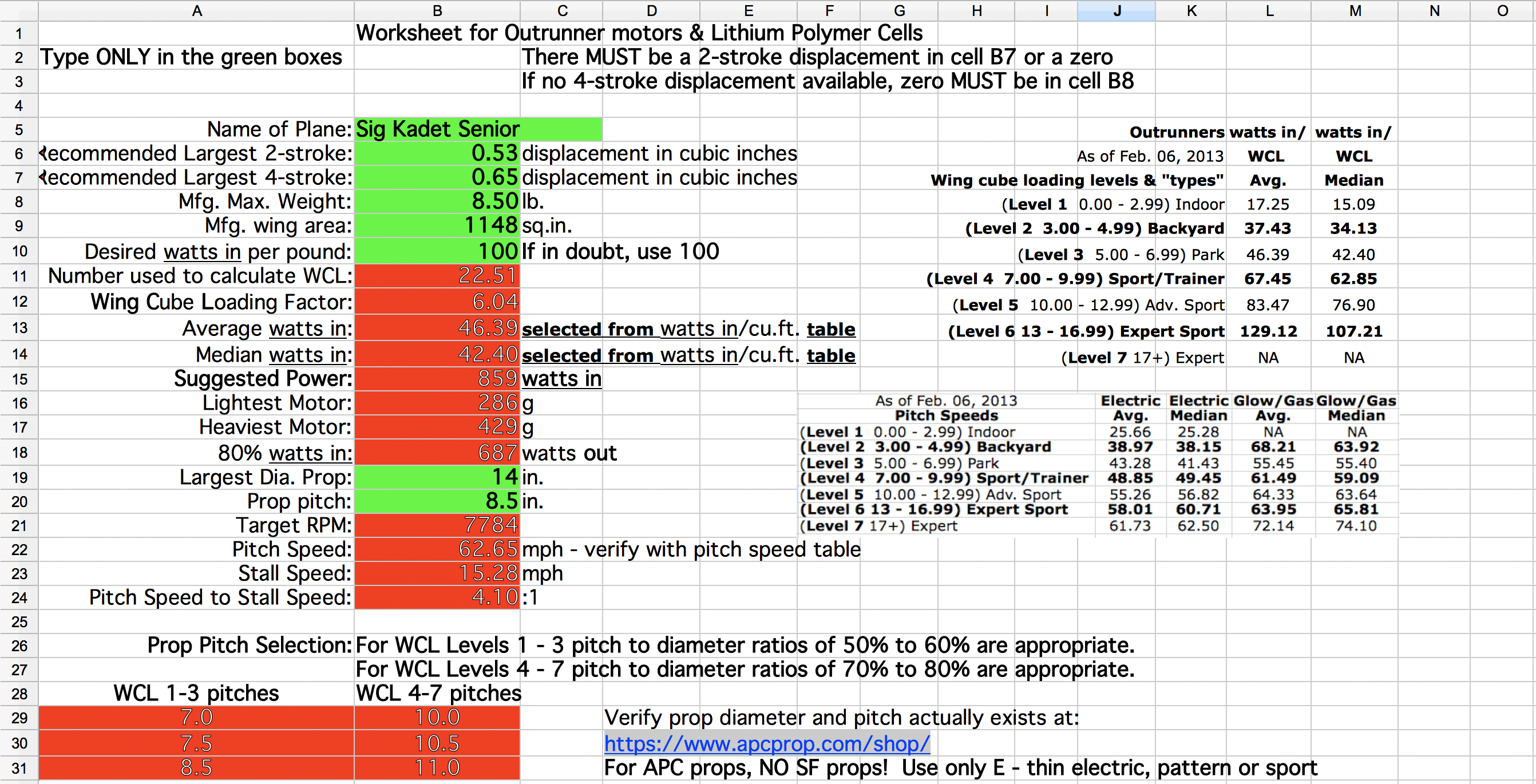

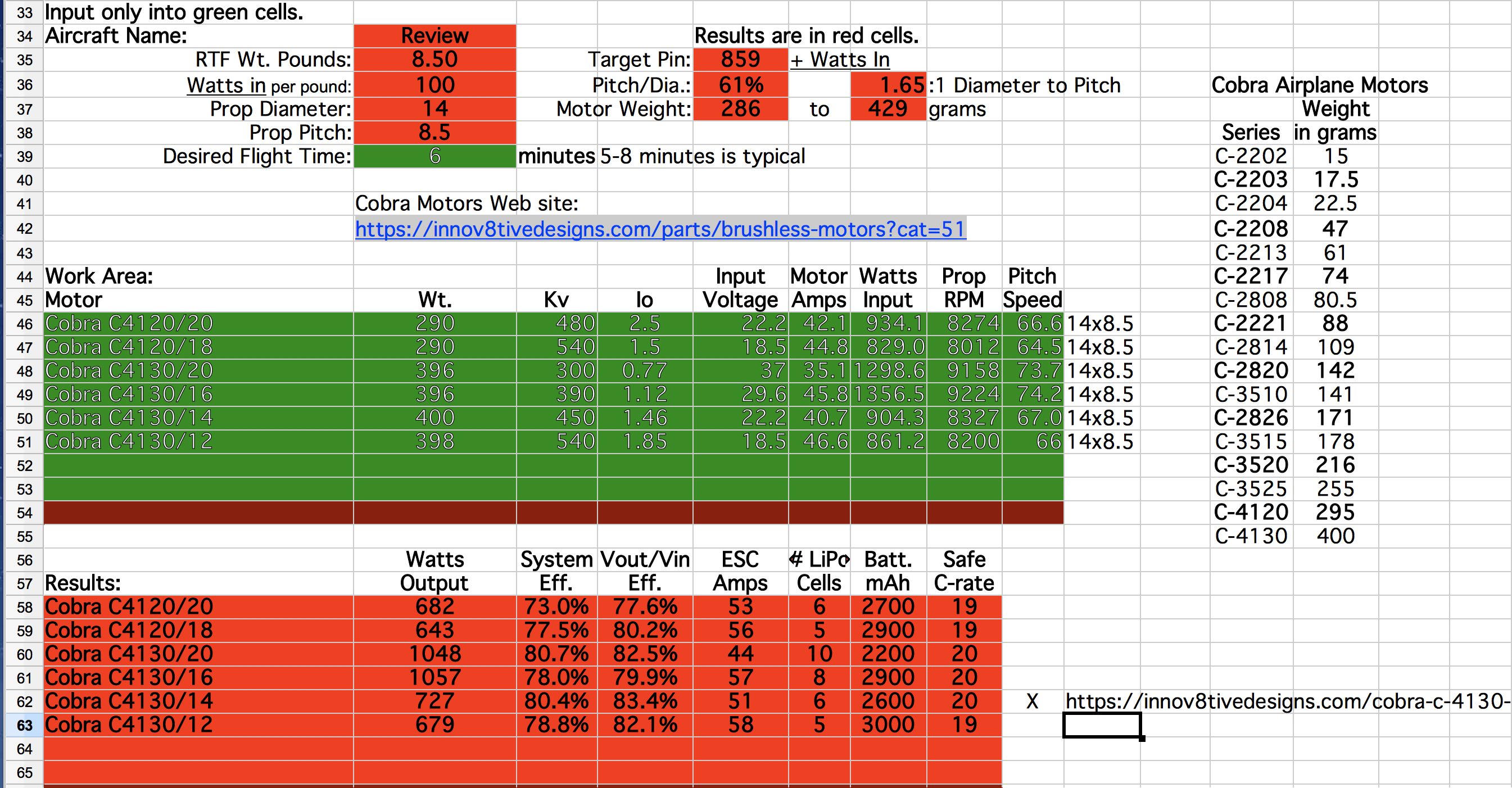

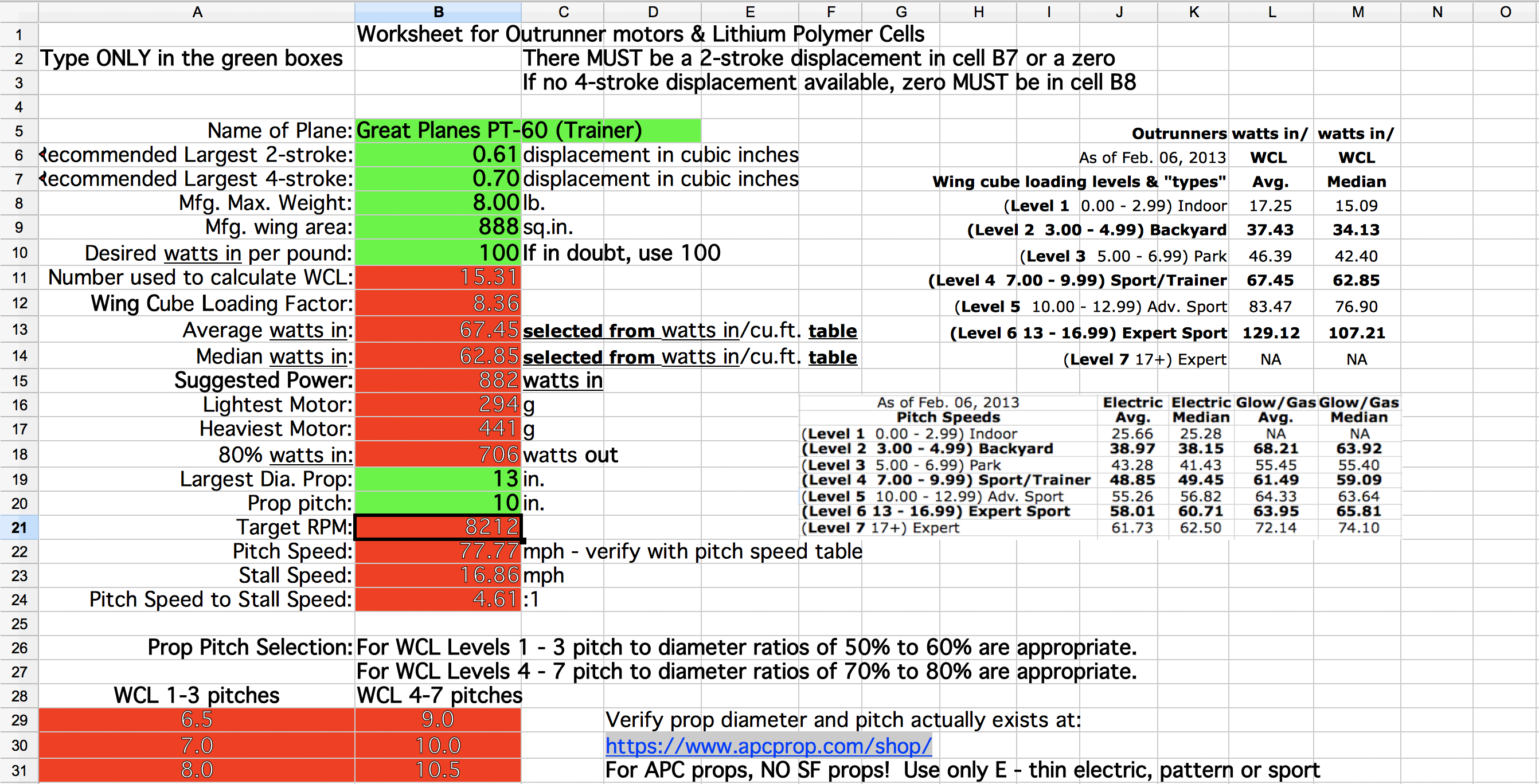

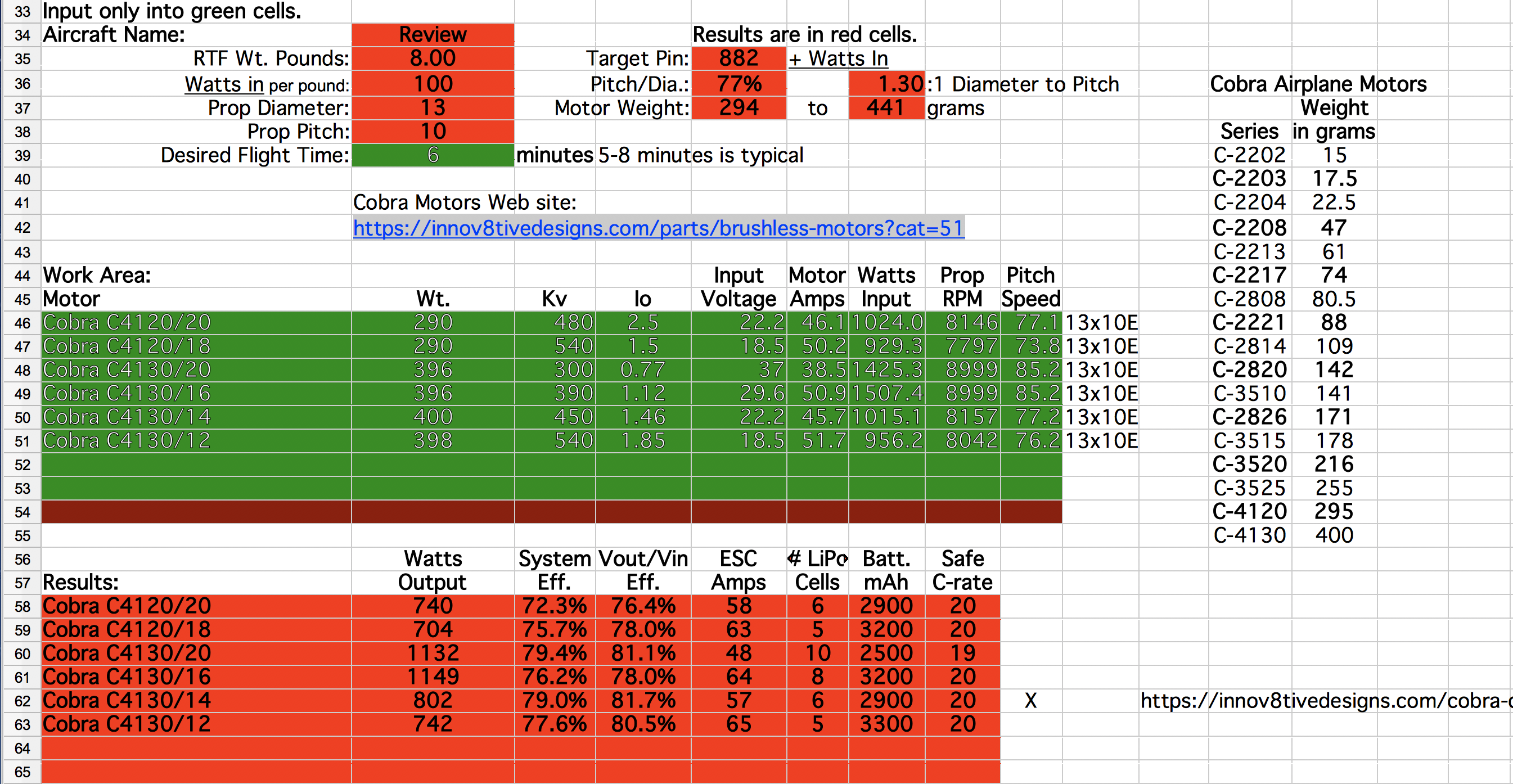

Hi Ken, My name is Aaron Heiner and I met you at the MRCS Fun Fly last month. Dave (Stacer) has spent a couple evenings with me out at the field - learning to fly is a lot of fun. He pointed me to your website - Wow! What a wealth of information. I'm very interested in building as well as learning to fly, and several years ago I purchased a Great Planes PT-60 kit. I recently dug it out and started working on it. I figured it would be a fun project for this winter with hopes of having the plane ready to fly for next spring. After being exposed to all the electrics at the field and seeing the convenience, cleanliness, etc. of electrics compared to Glow/Gas IC engines, I've been considering converting the PT-60 to electric. I read your article on Selecting Electric Power Systems and tried walking through the article and filling out your spreadsheet based on my understanding. I have attached it to this email and was wondering if you'd mind looking at it and tell me if I've filled it out correctly. Let me know if you see anything that looks amiss or if you have any questions. I look forward to getting to know all of you better. Thanks,

PS - I also have a SIG Kadet Senior ARF that I purchased from somebody years ago that already has an OS FS-70S glow motor on it. I've wondered if I should convert that one as well, but am not sure whether or not it would be worth the effort. I've attached that spreadsheet as well. Coincidentally according to my analysis the prop and engine selection would be the same for both planes. Hi Aaron, Wow, what a great job of trying to figure this stuff out for your very first time! :-) Unfortunately, Lucien Miller, owner of Innov8tive Designs, has moved the links on his Website around again since I last updated by link on the spreadsheet. I see you did find the links though. Congratulations! It took me quite awhile to see that you used 13 as your largest diameter prop in cell B19 on both planes and yet chose values for the APC 13x10E for the RCM Trainer and an APC 14x8.5 for the Senior Kadet. Using those values really made no difference in the Work Area inputs for both planes, but it did "throw me off" for a bit. Actually what you did was great! The only thing that changed in the results of the Work Area was the Pitch/Dia., pitch to diameter ratio. With an APC 13x10E for the trainer it changed to 77%, which is fine for this type of plane. For the Senior Kadet it changed to 61%, which is also fine for this type of plane. A good 55 amp to 65 amp ESC should work fine in both planes, as I've allowed for a 20% overheard in the recommendation. I just checked and there seems to be a lot of 6S 3000mAh LiPos around. I've used the brand linked to before, but not 6S, so take this recommendation with a grain of salt. You might want to ask Denny Summer what 6S packs brand(s) he likes. I'm attaching your beautifully completed spreadsheets with the simple changes I made and I have their names appended with -KM so as not to overwrite your originals. See ya at the flying field, Ken

The link to download the spreadsheets in .xls format can be found here. Motor Naming Conventions Question

Keith and Ken - Thanks again for making the journey to join the festivities for John's induction into the AMA Hall of Fame. John was embarking on some new kits. He asked me about how to label the power systems he will create for each aircraft. The power systems will include the motor, ESC and prop. His question revolved around whether to use terms like "Power 25", "Power 32", etc. equating to a glow version or some other nomenclature. Here are my thoughts. There are 3 types of customers. For those of us who are familiar with the expected performance of a glow engine the "Power 25" name is helpful. To anyone who is only into electrics it is meaningless. For those that are only looking for a turnkey kit and power system the name of the power system is meaningless. They will buy what is recommended. For those who want to use some power system we may have there is a need for an additional source of information. The use of Motor Calc or some other program would help but my experience is that most people won't bother. My suggestion is that the name could be "Power 25" but that all the specs for the components be specified in detail. For example: The AJAX Wizbang motor has 1200Kv which, with a 3 cell LiPo (12.6 volts), will turn an 8x 6prop at about 12,000 RPM and draw 40 amps. With this information I can see if I have a motor, ESC, battery with similar characteristics. I have used this type of information myself with numerous projects. Hint to Ken and Keith - That is why I contact you for confirmation of my SWAG. If you have a moment I am sure that John would appreciate any insight you can provide. Thanks,

From Keith Shaw via email I think the days of trying to relate equivalent electric power to glow are long over. There are electric fliers in every club now, so word-of-mouth about quality and performance is much more important. Electrics are so much more versatile (than glow motors KM) that it is a disservice to electric motors to try to link them to the much more restricted glow engine. By juggling cell count and prop, a "25" name could easily function as a mild .15 to a hot 40. By juggling nitro and props, a .25 engine MIGHT be able to fill the need of a .20-.30 I think the better way is the dimensions of the stator and Kv, like AXI, Cobra, Scorpion, BadAss, Predator, and endless others have adopted. The first couple of digits indicate a class of power capability, while the last two plus Kv fine tune the behavior at cell count and prop changes. Anyone who is at the point of adapting a power system package to their own needs is probably already familiar with these concepts, so as long as stator dimensions, Kv (maybe also R and Izero), max current and max power for each number of cells are included somewhere on the advertisement and/or instruction sheet, they will be fine. It would be some extra work for you, but you could bench test appropriate props at various cell counts and offer a table of the results on your website. If there are only a few power system packages offered, this would be reasonably easy to do. Lucien (Miller KM) does this at innov8tive designs.com. He has a good set-up and really does test samples of each of his products. This method is vastly superior to simulation programs like MotoCalc, Ecalc, or DriveCalc. Those depend on accurate motor parameters, ESC parameters and battery quality (internal resistance). DriveCalc is the most accurate, but only to about 10%, and is mostly suited to European products. Hope all this helps.

From Ken Myers via email Hi Folks, Keith is so right about the versatility of electric power systems and points to some excellent sources! Would you expect anything less! ;-) Personally, I like using weight, in grams, and Kv to identify motors. There are two reasons for this. For outrunner motors, weight can give a somewhat good idea about how much power a given motor might be able to handle. Many times the stator dimension is not given for many motors and the outside dimensions are given and those outside dimensions can be confused with the stator dimensions. If you look at the Power 25 Brushless Outrunner Motor, 1250Kv: 3.5mm Bullet on Horizon Hobby's Web site, there are no stator dimensions given. The outer diameter is given as 36mm and length at 53mm. The weight is given as 0.4 with no units. I'm guessing that the missing unit is pounds and that would be 6.4 oz. or about 181g. In my article "Selecting an Electric Outrunner Motor Power System for an ARF, Kit or Plans Built Electrically Powered or Glow Conversion Prop Plane" By Ken Myers, Original date of publication March 2017, Article and Spreadsheet Workbook updated April 2021" I have a chart that shows the Cobra C-3515 line of motors has a weight of 178g, obviously close to the weight of the "25". The Cobra C-3515/12 weighs 178g and has a Kv of 1100, which is the highest Kv for the 3515 series and not quite as high as the "25" with a 1250Kv. The C-3525/12 has a maximum continuous amp rating of 45 amps and the "25" rating 50 amps. The two motors are therefore somewhat similar. As Keith noted, Lucien Miller has prop charts for his motors and they can be extremely useful. The prop chart for the C-3515/12 is here. For props the "25" notes only "8x6E to 8x8E (4S) or 8x8E to 10x10E (3S)" while Lucien's tested chart shows a lot more possibilities. By looking at, and comparing the data, it can be seen that weight, in grams, and Kv can be used to find similar motors of different brands. To me, this means that whatever motor and battery cell count John uses, and finds successful, for his prototype power system, he can then recommend a weight, in grams, and the noted Kv for a similar motor with the same number of LiPo cells. I think Joe was right about recommending a "turn-key" power system and letting those who know use it as a guide, and those that donŐt know can just purchase the recommended power system. Ken One Way to Keep Your Thumbs Limber in a Michigan Winter

An old fiend sent along a link to a YouTube video he recently posted regarding keeping his fingers limber for RC flying during Michigan's winter. The subject of the email was, "Unremarkable, except, I was sitting inside the house in my slippers". The title of the video is "Cinelog 25 Winter Flight from inside the House". The URL is https://youtu.be/ZapePcSlsMs. Enjoy the video.

Merry Christmas and Happy New Year to all! To Reach Ken Myers, you can land mail to the address at the top of the page. My E-mail address is: KMyersEFO@theampeer.org |