|

Flying High With Electric Power!

The Ampeer ON-LINE!

Fly the Future - Fly Electric! |

Site Table of Contents

| President: | Vice-President: | Secretary/Treasurer: |

| Ken Myers | Richard Utkan | Rick Sawicki |

| 1911 Bradshaw Ct. | 240 Cabinet | 5089 Ledgewood Ct. W. |

| Commerce Twp., MI 48390 | Milford, MI 48381 | Commerce Twp., MI 48382 |

| (248) 669-8124 | (248) 685-1705 | 248.685.7056 |

| ||

| Board of Directors: | Board of Directors: | Ampeer Editor |

| David Stacer | Arthur Deane | Ken Myers |

| 16575 Brooklane Blvd. | 21690 Bedford Dr. | 1911 Bradshaw Ct. |

| Northville, MI 48167 | Northville, MI 48167 | Commerce Twp., MI 48390 |

| 248.924.2324 | 248.348.2058 | 248.669.8124 |

| Mailed Ampeer printed subscriptions are no longer available.

The Ampeer is FREE on-line in Acrobat .pdf format and HTML with active links! | ||

| The Next Flying Meeting:

Date: Saturday, June 13 Time: 10 a.m. Place: Midwest RC Society 7 Mile Rd. Flying Field | ||

| What's In This Issue? | ||||

| Upcoming Skymasters' Electric Fly In Info on this upcoming Lake Orion, MI event. | Upcoming CARDS' Electric Fly In Info on this upcoming Lansing, MI area event. | |||

| Reminder About EFO Flying Season Meetings Ken shares that EFO Flying meeting dates are tentative. | Upcoming Keith Shaw Birthday Party Electric Fly-in 2015 - Info and map for this upcoming event. | |||

| Speaking of the Birthday Fly In Plenny Bates shares a photo of Bob Livin's plane at 2014 Keith Shaw Birthday Fly In & news on a very good lubricant. | Selecting a Brushless Outrunner Motor Power System for Sport and Sport-Scale Airplanes (Part 1) Ken explains explains his latest technique for selecting a power system. (Part 1) | |||

| 31st Annual Mid-America Electric Flies 2015, info and links to the flyer and hotels and field map. | ||||

|

The Skymaster's Electric Fun Fly is scheduled for SUNDAY, June 28. It will be held at their Scripps Road Field. Scripps Road is between Joslyn and M-24 in Lake Orion, MI. The start time is 10:00 AM. This event is a full day of flying. There will be Electric Power open flying from 10 a.m. until 8 P.M. Pilot prizes are provided for participants. Contact CD: Pete Foss Email: electricfly@skymasters.org Upcoming CARDS' Electric Fly In

The Capital Area Radio Drone Society (CARDS) Electric Meet is Saturday, August 22, 2015. There field is located at 8328 Otto Rd., Grand Ledge, MI. Time is from 9 a.m. to 9 p.m. The Landing Fee is $15 which includes pizza & a soda. The field is available to registered pilots for electric only open flying on Friday Aug 21st from 4-9:00 pm, Pilot pre-registration and Spectators are welcome. Pilot and airplane requirements:

Site Accomodations:

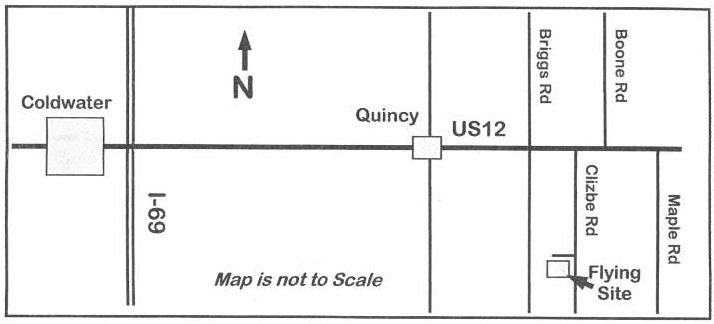

Contest Director: Marv Thomson Reminder About EFO Flying Season Meetings Dates given for the flying season EFO flying meetings are tentative. The date depends on the weather and may change from the one noted in the monthly Ampeer. The EFO Web site has the most current information posted. Also, emails are sent to EFO members if a date change is required. Upcoming Keith Shaw Birthday Party Electric Fly-in 2015 The Balsa Butchers will once again be hosting the "Keith Shaw Birthday Party Electric Fly-In" at their field near Coldwater, MI. The event will take place on June 6 and June 7, 2015. Contest Director: Dave Grife - E-mail: grifesd@yahoo.com or Phone: 517.279.8445

The Flying Field will be open Friday, June 5 for early arrivals. Saturday, June 6, hours are from 9 a.m. 'til 4 p.m.

Landing Fee is $15 for the weekend. Directions: Quincy is approximately 4.5 miles east of I-69. Clizbe Road is approximately 1.6 miles east of Quincy. The Flying site is approximately 1.5 miles south of US-12 on the west side of Clizbe Road. |

|

From Plenny Bates via email  This is the first flight of Bob Livin's Boomer Bus at Coldwater in 2014. I did a little photo shop work to take some farm equipment out of the tree line and a little deeper blue to the sky. Kerry Lawrence did the Photo Shop work. Also Most of us would not buy an expensive medication that contains "snake oil" but I have purchased plenty of "snake oil" nostrums for handyman problems. Finally I've found one that seems to work. It is Dupont Teflon Non-Stick Dry-Film Lubricant, which is made in Canada by Finish Line Tech. Inc. I have used it only on 2mm screws that hold the cover on the plastic Multiplex servo can. The screws are a bear to drive, but this dry to touch (after the carrier evaporates) lube remarkably reduced the force needed. It should be found at your local hardware store on the shelf with the snake oil. Selecting a Brushless Outrunner Motor Power System for Sport and Sport-Scale Airplanes (Part 1)

Preface: This article contains information on selecting a power system using a brushless outrunner motor for single motor AIRPLANES that fly on the wing. This method does NOT apply to multi-engine airplanes, helicopters, airplanes that will be used to do mostly 3D type flying, electric ducted fans (EDFs), extremely 'fast' propeller driven planes, indoor flyers, backyard flyers, and multi-rotors. Many of the almost ready to fly (ARF) airplanes come with the servos, the electronic speed control (ESC) and a brushless outrunner motor installed. The prop is usually provided by the supplier. The only thing the RC pilot needs to provide is a receiver and the recommended 'size' (number of cells & capacity) lithium polymer (LiPo) battery. Some ARF airplanes come only with the airframe completed and ready to assemble. The supplier usually recommends the servo 'size' and the power system requirement, or a range of requirements. Most of the small, fully assembled, ARF airplanes are ready to fly with the addition of a battery to supply the power system and onboard radio system. Usually, all that is required is the binding or linking of the installed receiver to a specific brand 2.4GHz transmitter. The transmitter might be supplied in a ready to fly (RTF) system or the pilot might be able to bind it to one that is already on hand. Typically, on larger than indoor ARF planes, there is some type of final assembly required. Some people build an airframe from a kit or plans. The kit supplier, or plans provider, may recommend a power system 'size' in some way and recommended the servo 'size'. Sometimes the builder is required to make the power system and servo selection based on experience. In the days of glow powered model airplanes, there was an 'accepted or understood' relationship between the stated cubic inch (cu.in.) displacement of the motor and its 'power'. Changing from a .45 2-stroke to a .60 2-stroke usually increased both the actual power to the propeller, whose diameter usually increased, and the power that the pilot perceived. The following example shows why.

Electric motors do not have 'sizes', in the typical sense of the word, as it applied to glow powered model aircraft. The suppliers of electric outrunner brushless motors that provide equivalent glow 'size' information, such as 25, 50, etc., are doing a disservice to the hobby and confusing many. With ever increasing loads, a given electric motor will continue to draw power through the system until it self-destructs. That does not take into account the electronic speed control (ESC) or battery, which may, or may not, self-destruct before the given motor. It is an extremely gross over simplification to compare an internal combustion engine's ability to deliver power to a propeller by noting only its cubic inch displacement. It was done because it was a 'handy' reference that could be easily understood. An overly simplified version used to compare one brushless electric outrunner motor's useful potential to another is to note its mass in grams (g) and its generator constant in RPM per volt (RPM/volt), which is annotated Kv. Unlike the overly simplified internal combustion comparison using only the displacement, the outrunner comparison must use both the mass (weight in grams) and RPM per volt number, Kv. Mass cannot be used alone. A brushless outrunner's mass, in grams, does not need to be changed to increase the 'potential' performance. The 'potential' performance can be changed by changing the prop size, its load. This is true, but in a more limited sense, for the glow engine as well. The big difference between the glow engine and the electric motor outrunner is how much the load, the prop diameter and pitch, can be varied through a useful range. The glow engine has a relatively narrow range of useful diameters and pitches. Comparatively, the electric outrunner has quite a broad range of useful diameters and pitches. A Cobra C-3525/12 brushless outrunner, weighing 253 grams (g), with a Kv of 650 RPM/volt, using a 4S LiPo battery, has a useful prop range from an APC 11x10E through an APC 15x6E. Most 2-stroke glow motors, that could turn an 11x10 propeller in its best efficiency range, could not turn a 15x6 propeller in that same range. The following example demonstrates the usefulness of this 'wide' range of props on the Cobra C-3525/12 motor using a 4S LiPo battery. APC 12x8E, 14.8V, 29.09 amps, 430.5 watts in, 7,857 RPM, calculated pitch speed 59.5 mph, a simple power out formula yields 334 watts out for an approximate system efficiency of 77.5%. APC 14x8.5E, 14.8V, 41.01 amps, 606.9 watts in, 7,282 RPM, calculated pitch speed 58.6 mph, a simple power out formula yields 443 watts out for an approximate system efficiency of 73%. The following example uses an increased battery 'size' to 5S LiPo, and an increased propeller size over the 12" example. APC 13x8E, 18.5V, 49.71 amps, 919.6 watts in, 8,849 RPM, calculated pitch speed 67 mph, a simple power out formula yields 656.6 watts out for an approximate system efficiency of 71.4%. Using 100 watts in per pound of ready to fly (RTF) airplane weight, a good performance number, the Cobra C-3525/12 can be useful in a 4.3 lb. (69 oz.) airplane to a 9.2 lb. (147 oz.) airplane. A single glow engine could seldom, if ever, be recommended for that wide of a RTF weight range. Using an outrunner with more mass does not necessarily mean more power to the prop if the battery and prop are kept the same. The Cobra C-4120/18 weighs 290g, which is about 40g heavier than the Cobra C-3525/12. It's dimensions are also larger than the Cobra C-3525/12. Thus, it is a 'bigger' motor. For comparison to the Cobra C-3525/12 using a 5S LiPo and turning an APC 13x8E, the data for the larger C-4120/18 using a 5S battery and an APC 13x8E yields: 18.5V, 37.61 amps, 695.7 watts in, 8,306 RPM, calculated pitch speed 62.9 mph, a simple power out formula yields 555 watts out for an approximate system efficiency or 79.8%. The power out of the 'larger' motor, the C-4120/18, is about 15% less than the 'smaller' C-3525/12 with the same battery and propeller. Why? The 'smaller' C-3525/12 has a generator constant of 650 RPM per volt and the C4120/18 has a generator constant of 540 RPM per volt. More of the C-3523/12's potential output power is being used than the potential power output of the C-4120/18. Another way to think of it is that the 'heavier', 'bigger' motor has the potential to handle more energy conversion, but given the same prop and battery and a lower Kv, it is not even equal in actual output power to the 'lighter', 'smaller' motor. The Cobra C-3525/10 has the same dimensions and weight as the C-3525/12 but uses a 10-turn wind of heavier gauge wire instead of a 12-turn wind of comparatively lighter gauge wire. Both motors have the same mass, 253g. The data for the C-3525/12 turning a APC 12x8E on a 4S LiPo is repeated below.

The data for the the Cobra C-3525/10 is

The power supplied to the APC 12x8E prop by the C-3525/10 increased by over 30%. The previous examples demonstrate that there is not a direct 'size' relationship to power with electric motors. There is a 'size' relationship to maximum potential power, but not to usable power with a specific load and input voltage. Read with caution statements such as, "I put a new Whiz-Bang brushless outrunner in my Extra 300 to replace the stock motor and it has really come alive." There are some outrunners that can have a bit more efficiency than some others weighing the same with approximately the same generator constant, Kv. In general, the most commonly purchased brushless outrunner motors (read that not seriously expensive), that weigh about the same and have approximately the same Kv, provide approximately the same power to the same prop using the same battery and ESC. Simply changing the motor to a motor with a similar weight and Kv does not make a huge change in performance, in most instances. Using a higher C-rated LiPo battery might increase the performance marginally, but for the performance to increase noticeably, the prop needs to have a larger diameter and/or more pitch, the number of cells increased in the battery (voltage increase) or the generator constant, Kv, needs to be a higher number. Each, and all, of the changes that increase the power cause an increase in the amp draw. Increasing the power affects the ESC rating required for safe operation. It might also affect the battery 'size' in milliamp hours (mAh), its capacity. A higher capacity battery might be required to maintain the desired flight time. Do not attempt to select any power system without having a power meter. The power meter is used to verify the proper selection of the components of a power system. All of the power system components, motor, electronic speed control (ESC) and battery, must be used safely within their individual specifications. To keep all of the individual components of the power system 'happy', use the 80% Rule of Thumb. Illustrative Examples:

The motor's continuous amp rating indicates that a 50-amp rated ESC should be fine since, applying the 80% rule of thumb, 80% (0.8) * 52 amps = 41.8 amps. That still leaves plenty of 'headroom' for the ESC. Ideally, the ESC should be rated for 52 amps or greater, but like all rules of thumb, there is some 'wiggle room'. From a previously noted example for the Cobra C-3525/12:

The ESC must be rated for at least 50-amps and 5S LiPo (18.5V) operation. A quick and dirty method to estimate the required battery capacity is to divide the static amp draw, 41.72 amps, by 2. That would be about 21 amps for this example. Multiply the halved static amp draw by the desired number of minutes of flight time, usually somewhere between 5 and 8 minutes for this type of plane. For the example, 7 minutes is used. 21 amps * 7 minutes = 147 amp minutes. Divide the amp minutes by 60 minutes, which is 1 amp hour. 147 amp minutes / 60 minutes = 2.45 amp hours. Change amp hours (Ah) to milliamp hours (mAh) by multiplying by 1000. 2.45 amp hours * 1000 = 2450 milliamp hours (mAh). For long life, LiPo batteries should not be emptied to more than 80% of their capacity. The inverse of 0.8 (80%) is 1/0.8. 1/0.8 = 1.25. 2450mAh * 1.25 = 3062.5mAh. That can be rounded to 3000mAh. A 5S 3000mAh (3Ah) LiPo would be suitable for this system and should provide approximately 7 minutes of flight time without draining the battery too far. Of course the time must be verified in actual practice. To calculate the safe C-rate of the battery, divide the anticipated maximum static amp draw by the amp hours of the battery. 42 amps / 3Ah equals an anticipated maximum C-rate of 14. Apply the 80% rule to the anticipated maximum C-rate. 14 [anticipated maximum C-rate] * 1.25 [inverse of 80%] = 17.5C [safe C-rate]. Round to 20C. Always round up. The battery for this system, to fly approximately 7 minutes with the motor, ESC and battery with plenty of 'headroom', is a 5S 3000mAh 20C LiPo. From another previously noted example using the Cobra C-3525/12:

Some changes can be made to the ESC and battery requirements when using this 4S system. The motor's continuous amp draw is no problem. For the ESC rating, apply the 80% rule of thumb to the anticipated 29 amp draw. 29 amps * 1.25 = 36.25 amps. An ESC capable of handling a 4S LiPo at 35 amps or 36 amps is sufficient. There is no reason not to use a 50-amp rated ESC, except for the slight weight penalty. Using the formulas from above and the same desired flight time of 7 minutes.

The battery for this system, to fly approximately 7 minutes with the motor, ESC and battery with plenty of 'headroom', is a 4S 2200mAh 20C LiPo. Start by selecting a Target Prop 'Size' There are several considerations when selecting a prop for a given airframe. Diameter In general, use the largest diameter prop that gives approximately 1-1/2" of ground clearance. Sometimes that is not possible. Single 'engine' pusher configurations tend have clearance limitations with the fuselage. Some planes just 'look' wrong with a huge diameter propeller on them. A smaller diameter prop might be aesthetically desirable. Pitch "Another factor to consider is the diameter/pitch ratio of the prop. A 1:1 ratio may be usable for high speed pylon racers, but for scale planes and aerobatic types 1.3:1 to 1.7:1 are better ratios. For high drag or slow-flying aircraft a 2:1 ratio is more suitable." Sometimes the inverse of Keith's ratios are easier to comprehend. The inverse yields the pitch to diameter ratio rather than the diameter to pitch ratio. 1/1.3 equals a pitch that is 0.769 of the diameter or 76.9% of the diameter. 1/1.7 equals a pitch that is 0.588 of the diameter or 58.8% of the diameter. 2:1 becomes 50% of the diameter. While Keith's recommendations are excellent, I've used an APC 12x10E in many applications. There has never been a problem coming out of the grass, or excessively long takeoff runs, using this ratio, 0.833 or 83.3% of the diameter. Keith's diameter to pitch ratio for this would be 1.2:1. At least four of my flying buddies have a SIG Four-Star Forty. I like the way the plane flies, so that was my winter building project. This plane, originally designed for a .40 2-stroke glow engine, has been around for a long, long time. There have been numerous conversions to electric power. Almost every electric conversion, of this conventionally geared design, has used longer main gear and/or larger than recommended diameter wheels. My goal for this plane was to select a power system that could use the kit's supplied landing gear and recommended wheel diameter. After measuring the plans, the largest diameter prop was determined to be a 12". I use APC thin electric props on almost all of my planes. The 12" diameter APC thin electric props are the; 12x6E, 12x8E, 12x10E and 12x12E. The 12x6E's pitch ratio is too low for this type of sport plane and the 12x12E's ratio is too high. I elected to use the 12x8E (1.5:1 or 66.67% ratios) as the target prop. The estimated, or actual, ready to fly (RTF) weight in pounds is useful in determining the target power in (Pin), watts in, for the aircraft. Most trainers, although not required, sport and sport scale planes fly quite well using 100 watts in per pound of RTF weight. SIG notes the RTF weight as 4.75 lbs. (76 oz.) using a 2-stroke .40 engine. I rounded this to a target weight of 5 lb. (That is exactly what my plane's RTF weight turned out to be.) 5 lb. at 100 watts in per pound is 500 watts in. That should certainly fly this plane well, but I decided to set my target watts in to 600. That is about 120 watts in per pound, if the target weight of 5 lbs. is achieved and the motor can be matched well. A target motor's weight in grams is determined by dividing the target watts in by a range of divisors. The divisors are based on watts in per gram of motor weight, watts in/g. |

|

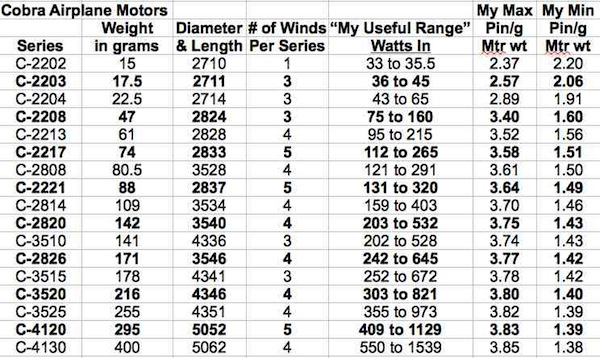

The table shows some typical watts in/g of motor weight that I have used on several very successful power system selections. |

|

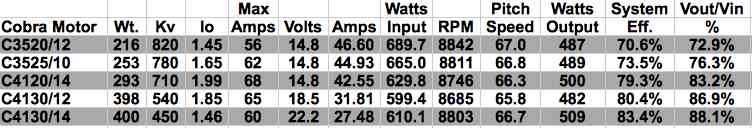

As demonstrated in the second table titled, "Cobra Airplane Motors", the watts in/g, or Power In per gram of motor weight, Pin/g, varies quite a bit by the motor's mass. Even though I personally have never used any Pin/g of motor weight much over 2.5, the table indicates that could be acceptable, depending on the mass of the motor. 'Lighter' motors could have been used in my Fusion, Ryan STA and Sonic 500. The ones chosen were a bit of 'overkill', but they helped the horizontal balance, AKA the CG, in each of the planes a lot. Even though the table indicates a wider range of Pin/g of motor weight, I find it convenient, for the types of planes I fly, to use 1.5 watts in per gram of motor weight to 3 watts in per gram of motor weight as the weight range to start the motor selection process. My target watts in for the Four-Star Forty is about 600. 600 / 1.5 = 400g for the heaviest motor and 600 / 3 = 200g for the lightest motor. The target motor weight range is 200g to 400g. That is a pretty wide range! To assist in the selection process, I used the table for Cobra Airplane Motors. Most of the Cobra motors are produced in several winds. The table provides the weight in grams, the outside diameter and length in millimeters and the number of winds available. The outside diameter and length were combined into a single number with the first two digits representing the external diameter and last two digits the external length. This is one common way that many outrunner motor suppliers, but not all, annotate their motor 'sizes'. I added the columns for MY Useful Range in Watts In, to give ME an idea of MY typical power usage range. The table is used to narrow down the selection to a few specific motor series. The motor for the Four-Star Forty could weigh between 200g and 400g and should be able to handle 600+ watts in. The table shows that the C-3520, C-3525, C-4120 and C-4130 series fit the criteria of weight and watts in. There are a total of 17 motors with various Kv numbers in the four series to consider. The Kv number represents the generator constant in RPM/volt and is annotated by Innov8tive designs as Kv. Lucien Miller has prepared Propeller Data Charts for all of the Cobra motors from actual motor testing. Going through the 17 individual Prop Data Charts on the Innov8tive Designs Website does not really take very long. Five usable motors were located, the C-3520/12, C-3525/10, C-4120/14, Cobra C4130/12 and C-4130/14. From all of the Cobra airplane outrunner motors, there were now only five to consider for turning an APC 12x8E for at least 600 watts in. The motors are listed in the table. |

Two 'helpful' data points for comparing and selecting THE motor are the system efficiency and the percent of the input voltage to the prop under load. An extremely rough idea of the system efficiency can be estimated using the RPM divided by the Kv times the amps minus the Io (no load current) divided by the watts in. Example for system efficiency: C-3520/12 ((8842 RPM / 820 Kv) * (46.6 amps - 1.45 amps)) / 689.7 watts in

A rough way to calculate the percentage of the input voltage is to divide the noted RPM by the noted Kv number divided by the input voltage. Example for percent of voltage drop:

Keep in mind that these are rough approximations, but good enough for comparing one motor to another. Note that as the weights of the motors increase, so does the system efficiency and input voltage percentage. The 'rough' calculations are not all that accurate, but 'good enough' for a comparison. The calculations show the highest RPM, 8842, with the lowest watts out, 487 for the C-3520/12. Both the method of calculation for power out and the actual measurements provided by Lucien Miller at Innov8tive Designs can cause an error. Still, all five motors should produce about the same power out turning an APC 12x8E at about 8800 RPM. All five motors should 'work' in this application. 31st Annual Mid-America Electric Flies 2015 Saturday, July 11 & Sunday, July 12

|

To Reach Ken Myers, you can land mail to the address at the top of the page. My E-mail address is: KMyersEFO@theampeer.org