Tower Pro 3520-07T (current nomenclature on Tower pro Web site): A Review

By Ken Myers

This article first appeared in the July 2007 Ampeer.

TOWER PRO Electron Co, Ltd. is located at Building 12-204# Yingshui section2, Minle, Longhua, Baoan District, Shenzhen 518131, PR China. They produce and supply to hobby market distributors; motors, ESCs, servos, propellers and other accessories. Their website is located at www.towerpro.cn.

This review came about because I had previous experience with the Tower Pro 3520-6 motor in three of my airframes, the Sport Stik 40 ARF Low Wing Aircraft, Ryan STA ARF and Sonic 500 ARF, all available from (www.hobbypeople.net) Hobby People. You can read my build threads for two of these planes on RC Groups, which include information on the -6 motors; "Sports Aviation Ryan STA 40 ARF Build" www.rcgroups.com/forums/showthread.php?t=557165 and "Sportsman Aviation Sonic 500 25-46 ARF" www.rcgroups.com/forums/showthread.php?t=604271.

I became aware of, and interested in these motors because of a thread on RC Groups titled "TowPro BM3520-7 1KW??? Outrunner Motor"; www.rcgroups.com/forums/showthread.php?t=431127. Reading this thread it became apparent that there were at least two versions of the motor available bearing the names "Tower Pro 3520-7, BP 3520-7 or BM 3520-7". At that time, October 2005, Tower pro (spelling from their current Web site) did not show two versions of the motor and stated the weight as 237g.

After digesting the information on the RC Groups thread, I decided that the Tower Pro 3520-7 would be a good choice for my Sport Stik 40 ARF conversion. I ordered a 3520-7 from Milton, of RC Groups, and upon testing found it to be the "higher" Kv version, now known as the -6. That was not what I wanted, but I ended up using it in the Stik 40 along with a Tower pro 60-amp ESC. For the Sonic 500, because of the requirement for a smaller prop, I DID want, what by then was known as the TP 3520-6, the higher Kv version. I ordered it from BP Hobbies (www.bphobbies.com) because they were the only supplier I could find that specifically noted the -6. To this day, I believe a lot of suppliers selling the -7 are selling either version of this motor with no regard for the actual version being sent to the customer. Unlike BP Hobbies and United Hobbies, XUS Hobby (www.xushobby.com/servlet/Detail?no=109), BigERC (bigerc.com/product_info.php?products_id=60) and

True RC (home.comcast.net/~truerc/esc/escNmotor.htm) denote them as 3520-7. The suppliers all have different data for the motor, and obviously, except for BP Hobbies have never actually run one or even bothered to throw the motor on a scale! United Hobbies (www.unitedhobbies.com) seems to have the current data from Tower pro on their site for both versions.

Here are some highlights that demonstrate the confusion, from some suppliers Web sites to compare with my data. Note: All of the above information was copy and pasted from the noted Web sites on April 29, 2007. Web sites can change in an instant, so whether the information is still the same when you read this is anyone's guess.

Tower pro Web site:

3520-06T: Dimensions: ~45.5*72mm, Weight 262g, Operating Current 50A, Kv 700RPM/V, Prop 13*8;14*7, 5mm output shaft

3520-07T: Dimensions: ~45.5*72mm, Weight 262g, Operating Current 45A, Kv 600RPM/V, Prop 13*8;14*7, 5mm output shaft

Tower pro motor spreadsheet from their Web site (towerprocn.sh15.host.35.com/towerprocn/english/Manual/manual.html):

TowerProMotorSpec1209.xls spreadsheet showed:

3520-6T-10: Dimensions: ~45.5*72, Weight 262g, Io 2.2, Kv 700, Operating Current 50A, Max Load Current (A/60s) 65A, Max Power 1000W, 13*8/14*7APC-E

3520-7T-8: Dimensions: ~45.5*72, Weight 262g, Io 1.6, Kv 600, Operating Current 45A, Max Load Current (A/60s) 56A, Max Power 850W, 13*8/14*7APC-E

BigERC: $52.90, Dimensions: 42mmx37 mm, Weight with cables: 237g, Shaft diameter: 4 mm, KV: 830 RPM/V, Max current: 50A, No Load Current: 2.8A, Recommended prop without gearbox: 13x8, 14x7APC-E, For planes up to 7lbs

XUS Hobby: $52.90, DIMENSION: ?44.7*72.0 mm(includes shaft), WEIGHT: 237g, 5mm keyed output shaft, KV: 670, CURRENT: 1.2A-50A, PROPOLLER: 13*8/14*7APC-E

True RC: $52.00, 44.7 mm diameter x 72.0 mm length (includes shaft), Weight 245g, 5mm diameter keyed output shaft, Kv 670, Amps 50A, Recommended prop: 13x8 or 14x7 APC, Powerful motor for .60 size models and yet, this data also appears with the listing of this motor; PILOT RESULTS: Io: 1.6A (10v) KV: 550

BP Hobbies:

BP 3520-6: $52.95, Size: 44.7 mm x 72.0 mm, Weight: 237 g, Shaft Diameter: 5mm, Kv 730 RPM/V, No Load Current: 2.9A, Max Current: 50A, Suggested prop: 10 x 7 or 11 x 7 APC Sport, This motor is roughly equivalent to a .40-.50 sized glow engine and is recommended for planes up to 8 lbs, Do not exceed 700 watts with this motor!

BP 3520-7: $52.95, Size: 44.7 mm x 72.0 mm, Weight: 237 g, Shaft Diameter: 5mm, Kv 650 RPM/V, No Load Current: 1.6A, Max Current: 50A, Suggested prop: 13 x 8 or 14 x 7 APC Thin Electric, This motor is roughly equivalent to a .40-.50 sized glow engine and is recommended for planes up to 8 lbs, Do not exceed 700 watts with this motor!

United Hobbies:

TowerPro 3520-6, $25.00USD, Size: 45.5diam x 72mm, Weight: 262g, Shaft: 5mm, Kv: 700RPM/v, Idle Current: 2.2A, Max Eff Current: 50A, Max current: 65A, Max Power: 1000W, Suggested prop: 13*8, 14*7 APC-E

TowerPro 3520-7, $25.00USD, Size: 45.5diam x 72mm, Weight: 262g, Shaft: 5mm, Kv: 600RPM/v, Idle Current: 1.6, Max Eff Current: 45A, Max current: 56A, Max Power: 850W, Suggested prop: 13*8, 14*7 APC-E

Are You Confused Now?

If you carefully digest the above, you'll note that there is a lot of conflicting information! You are not the only person confused. In the December 2006 issue of Quiet Flyer, the noted, and extremely capable Steve Neu reviewed this motor in his "Power On" column starting on p. 48. In the text of his article he refers to the motor as the TowerPro TP3520/7, but the graphs on p.50 note it as the TP 3520/6, which is what his motor was. Steve gave the following information; 56mm long and has a diameter of 45.5mm, weight 268g, shaft 5mm, Kv 725, no load current 3 amps.

The Real Numbers for MY BP 3520-7

Motor w/leads: 261.2g/9.2 oz 89%

Mount & 4 screws: 8.55g/0.3 oz. 3%

Prop Adapter: 22.7g/0.8 oz. 8%

Total: 292.45g/10.32 oz.

Total w/3 clipped APP connectors & sandpaper on prop adpt. 295.8g/10.4 oz.

Motor shaft length: 72.5mm/2.85 in.

Motor shaft diameter: 5mm/ 0.196850 in.

Motor can length: 51mm/2 in.

Motor can diameter: 45.6mm/1.795 in.

Prop adapter length: 42mm/1.65 in.

Motor lead length: ~100mm/3.94 in.

Motor wire gauge: ~15 - I was able to strip the wire with the 14-gauge hole in my wire stripper

Drill Press Test to Determine Kv

1.85v, 1.86v, 1.845v using the AC setting on my Radio Shack multimeter - average: ~1.85v, drill press speed 1560 RPM - Kv ~627 Kt ~2.16

The Kv of ~625 indicates that this is truly the 7-wind version.

The prop nut was not drilled completely through for tightening, so I drilled it the rest of the way through. The "X" mount is longer on each leg than the one that came with the BP 3520-6 and needed no modifications.

My Testing

I do not have a motor dyno to do the sophisticated testing that Mr. Neu does, but my methods, used and explained here come quite close to matching the numbers in Steve's article when I tested my versions of the -6. Steve noted the Kv as 725 on his sample of the -6 and by using the drill press method on my -6 versions I came up with 730 and 737 respectively. I'd say that is close. Also, one of my -6 motors at 14 volts and 29.8 amps was running at 8940 RPM according to my Hyperion Emeter. One of Steve's graphs for 14v and 30 amps shows an approximate RPM of just slightly over 9000. Again, I feel that the numbers are reasonably close.

As I have mentioned in the past, I really like using the computer motor simulation tool called Drive Calculator. It is FREE at www.drivecalc.de and runs on both the Mac and Windows operating systems. I use Christian's method for gathering my data and entering it into the program.

How I Gather My Data

First, I carefully weigh the motor parts in grams using a balance beam scale. I measure the various motor parts and then draw the motor into a CAD program noting the important dimensions for future reference. I then verify the weights and measures one more time. Next I add trimmed Anderson Power Pole (APP) connectors to the motor and ESC and reweigh the motor. I use my Radio Shack # 22-168A Digital Multimeter set on AC to measure the AC volts using my drill press and then calculate the Kv using the gathered voltages and drill press RPM. I affix sandpaper to the prop adapter collet back plate for a better grip when tightening the prop. The battery or batteries are charged for the prop testing. While the battery is charging, I select and balance the props to be used for data point collection. The ESC is programmed. I clean the motor bell of any oil or grease to prepare it for a white strip of paper that will be wrapped around it and taped to the bell for the no load data gathering. The motor is fastened to the motor test stand for the static power tests and secured to my workbench. A flashlight is positioned to shine through the prop so that the shop lights may be shut off during the data gathering. I use a data record sheet, which I prepared, to record all of the data captured by the Hyperion Emeter, which is then transferred to a spreadsheet. I note the elevation of the testing, ambient temperature, air pressure, humidity and dew point. I collect five data points for each prop taken approximately five seconds apart and captured by the Emeter. I then record the gathered data from the Emeter. I do that for the four props that I gather data points for, and all motor runs are done using the same battery with no recharging. I note the temperature of the battery, ESC and motor after each of the data acquisition tests. Finally, I gather the no load data after the last prop test, when the motor is still warm. A white strip of paper is secured to the motor bell and a black marker line is run horizontally across the white paper so that the Emeter tach can be set to one blade and take the RPM readings along with volts, amps, etc. Once all of the data has been gathered, it is averaged, and the average data is inserted in the Drive Calculator program to create a simulation of the tested motor to be shared with others.

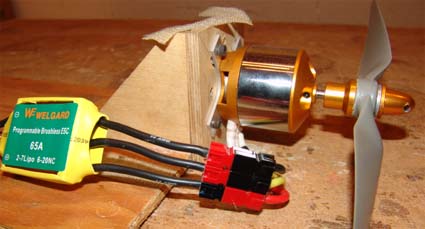

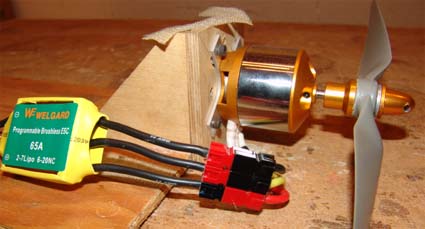

The ESC Used for this Test

The electronic speed control (ESC) is really a part of the brushless motor and becomes a variable when noting brushless motor performance. For this project, I chose the (www.welgardelectrics.com.cn) Welgard 65A. I purchased the ESC as a combo with the BP 3520-7 from BP Hobbies.

The first ESC was inoperative on arrival. It would not arm to program. Several hours were wasted trying to get it to work, which was a setback. I was especially disappointed since I "lost" 5 Anderson Power Poles on the returned ESC. It was returned on March 29 for replacement at a cost of $1.95 for the postage.

The replacement ESC arrived on Wednesday, April 25, 2007, 28 days later!!! To be fair, the ESC was in transit for 7 of those days, but it was at BP Hobbies for over three weeks before being replaced! That is EXTREMELY poor service. There were no instructions for programming the ESC packed with the original. I got the original programming off of the BP Hobbies Web site, but the replacement ESC came with printed instructions for programming using the transmitter while the ESC runs through a series of beeps.

The original ESC had yellow shrink around the whole unit. The replacement has the yellow shrink removed over the heat sink but the heat sink is covered with a green Welgard sticker.

Replacement Welgard 65A programmable ESC:

As delivered w/leads: 55.1g/1.94 oz.

With 5 trimmed APP connectors: 61.5g/2.17 oz.

Motor leads length: ~60mm/2.36 in.

Battery leads length: ~130mm/5.12 in.

Receiver lead length: ~210mm/8.3 in.

The replacement is slightly heavier than the original.

The replacement went correctly into programming mode and I programmed it to:

1. Cell Type and Number of Cells: NiMh/NiCD Auto Cell Count - I don't use cutoff voltage, I time.

2. Throttle Setting: Auto Throttle Range

3. Brake Setting: No Brake

4. Direction and Cutoff Type: Counterclockwise Rotation - that put the rotation the "correct" way for my wiring setup

5. Timing Mode Setting: 1-deg - For 2-4 Pole Inrunner Motors - I am testing the motor at the lowest timing setting.

6. Pulse Width Modulation (PWM) Setting: 8Khz - For low RPM and low pole count motors - My Jeti Spin 44 is set to this on a BP 3520-6 and is working okay.

Please note that I am using the "lowest" timing available. I don't need the "most" power for my proposed use of this system and I am going for efficiency. Advancing the timing to a higher setting will affect all of the numbers I am presenting here.

The throttle response is okay and better than the Tower pro 60A ESC that I have in the Ryan STA. It also appears to be working well with the 5S battery packs used for testing, while the Tower pro 60A really doesn't like 5S packs at all.

A Word About Timing

On April 30, 2007, I was going to gather new data points with the timing on the ESC advanced. The Welgard directions indicate; "15-deg-For 10-14 Pole Outrunner Motors" and "30-deg-For 10-14 Pole High-RPM Outrunner Motors". The page on the BP Hobbies Web site for this motor says, "Suggested ESC timing advance: 15-30 degrees". I know that I have read these figures before in various places as well. I went to the Castle Creations Web site to verify this information before resetting the timing on the ESC and redoing the tests. I found the following in the Phoenix 45 manual, and other Phoenix manuals as well, "Low Advance: May slightly decrease RPM and current draw, and will give longer runtime and a cooler motor and batteries. This is the preferred setting for outrunner motors." (Note: I underlined. It is not underlined in the manual. KM)

Anyone else confused? I decided to just let my 1-deg timing data stand, and I will continue to use "low" timing on my outrunners.

*Since this article was written, I have investigated the effects of different timing advance. To find out more about advancing the timing, read the timing article.

The Props

All of the props used to collect data points were APC thin electric. The are usually designated with the diameter by pitch followed by the letter E, i.e. APC 10x7E. As I have noted before, APC changed their thin electric prop design at least once, so it is really important to note the physical characteristics to determine which one is being used.

APC 10x7E: wt. 19.25g, hub thickness 10.2mm/0.40 in., purchased March 2007

APC 11x7E: wt. 21.5g, hub thickness 10.4mm/0.41 in., purchased unknown

APC 12x6E: wt. 23.75g, hub thickness 9.9mm/0.39 in., purchased unknown

APC 13x6.5E: wt. 24.9g, hub thickness 9.3mm/0.365 in., purchased March 2007

I believe that the 13x6.5E may be an earlier production version since it is light, compared to the others, and has the smallest hub thickness, even though it was purchased in March 2007.

The Batteries

For prop data point gathering a True RC 5S1P 4000mAh Li-Po, 5S1P 3000mAh Emoli, and 6S1P M1/A123 2300mAh pack were used. A Sanyo 10-cell 1700SCRC NiCad and Skyshark 4S1P 4000mAh pack were used to gather the no load data. I chose to use three different packs as I was still gathering comparative data on them.

The Results

As you read the following numbers, keep in mind that these results were obtained using 1-degree of timing on the ESC. The testing was done over a two-day period in my basement. On Day 1 the packs were heated for at least 6 minutes using a rice bag. On Day 2 the packs were at the ambient basement temperature. Also keep in mind that each prop was run five times for about 5 seconds before the data was captured. That means that the pack voltage was always highest when testing the first prop, the APC 10x7E and at its lowest voltage when the APC 13x6.5E data was gathered much further into the pack run. Only the averages for the five data point captures are presented here. The relative humidity in the basement was lower than noted as there is a dehumidifier running down there.

Ambient temperature has an affect on the outcome of any motor testing. Do not expect exactly the same results as provided here. The ambient temperature affects the prop and how it is "working" in the air and the battery. I do not have a powerful power supply to do motor testing, therefore I must rely on batteries. The battery temperature can make a difference in system performance. To see how temperature affects Emoli, Li-Poly and M1 (A123 System) cells, read my "Effects of Temperature On the Battery" article.

The Walled Lake, MI, USA elevation is about 715 ft. or 218m.

Day 1

Sanyo 10-cell NiCad No Load: 13.038v, 1.8 amps, 7944 RPM

Skyshark 4S1P 4000mAh Li-Po No Load: 16.326v, 2.1 amps, 9948 RPM

Pack 1: heated True RC 5S1P 4000

10x7E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.94 in/1013.9mb steady, Dew Point: 42.8 F/6C, Humidity 91%

Volts in: 18.914, Amps: 23.82, RPM 10512, Watts in: 450.5

After run temperatures: Motor: 85.4 F/29.7C, ESC 69.1 F/20.6C, Battery 92.6 F/33.7C

11x7E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.92 in/1013.2mb steady, Dew Point: 42.8 F/6C, Humidity 91%

Volts in: 18.318, Amps: 29.84, RPM 9906, Watts in: 546.6

After run temperatures: Motor: 81.3 F/27.4C, ESC 72 F/22.2C, Battery 94.8 F/34.9C

12x6E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.92 in/1013.2mb steady, Dew Point: 42.8 F/6C, Humidity 91%

Volts in: 18.346, Amps: 31.72, RPM 9852, Watts in: 581.9

After run temperatures: Motor: 92.7 F/33.7C, ESC 72.8 F/22.7C, Battery 109.6 F/43.1C

13x6.5E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.92 in/1013.2mb steady, Dew Point: 42.8 F/6C, Humidity 91%

Volts in: 17.512, Amps: 40.36, RPM 9000, Watts in: 706.8

After run temperatures: Motor: 102.3 F/39C, ESC 75.7 F/24.3C, Battery 100.6 F/38.1C

Pack 2: heated M1/A123 6S1P 2300mAh

10x7E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.87 in/1011.5mb falling, Dew Point: 44.6 F/7C, Humidity 94%

Volts in: 18.628, Amps: 23.3, RPM 10380, Watts in: 434.0

After run temperatures: Motor: 81.1 F/27.3C, ESC 68 F/20C, Battery 82.6 F/28.1C

11x7E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.87 in/1011.5mb falling, Dew Point: 44.6 F/7C, Humidity 94%

Volts in: 18.116, Amps: 29.18, RPM 9822, Watts in: 528.6

After run temperatures: Motor: 86.6 F/30.3C, ESC 68 F/20C, Battery 90 F/32.2C

12x6E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.86 in/1011.2mb falling, Dew Point: 44.6 F/7C, Humidity 94%

Volts in: 18.10, Amps: 31.04, RPM 9738, Watts in: 561.8

After run Temperatures: Motor: 99.2 F/37.3C, ESC 69.1 F/20.6C, Battery 89.1 F/31.7C

13x6.5E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.86 in/1011.2mb falling, Dew Point: 44.6 F/7C, Humidity 94%

Volts in: 17.45, Amps: 40.22, RPM 8982, Watts in: 701.8

After run temperatures: Motor: 111.3 F/44C, ESC 70.4 F/21.3C, Battery 102.5 F/39.2C

Pack 3: heated Emoli 5S1P 3000mAh

10x7E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.78 in/1013.2mb falling, Dew Point: 44.6 F/7C, Humidity 93%

Volts in: 18.478, Amps: 22.88, RPM 10308, Watts in: 422.8

After run temperatures: Motor: 83.2 F/28.4C, ESC 67.8 F/19.9C, Battery 98.6 F/37C

11x7E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.78 in/1013.2mb falling, Dew Point: 44.6 F/7C, Humidity 93%

Volts in: 17.92, Amps: 28.56, RPM 9726, Watts in: 511.8

After run temperatures: Motor: 90.8 F/32.7C, ESC 69.1 F/20.6C, Battery 107.5 F/41.9C

12x6E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.80 in/1009.1mb rising, Dew Point: 46.4 F/8C, Humidity 96%

Volts in: 17.796, Amps: 30.08, RPM 9600, Watts in: 535.3

After run temperatures: Motor: 99.2 F/37.3C, ESC 69.1 F/20.6C, Battery 89.1 F/31.7C

13x6.5E Ambient Temperature: 62 F/16.7C, Barometric Pressure: 29.80 in/1009.1mb steady, Dew Point: 46.4 F/8C, Humidity 94%

Volts in: 17.002, Amps: 38.2, RPM 8790, Watts in: 649.5

After run temperatures: Motor: 107.0 F/41.7C, ESC 76.4 F/24.7C, Battery 116.5 F/46.9C

Day 2

Pack 1: ambient True RC 5S1P 4000

10x7E Ambient Temperature: 65 F/18.3C, Barometric Pressure: 29.65 in/1004.1mb steady, Dew Point: 53.6 F/12C, Humidity 97%

Volts in: 18.282, Amps: 22.42, RPM 10212, Watts in: 409.9

After run temperatures: Motor: 85.3 F/29.6C, ESC 67.4 F/19.7C, Battery 68.0 F/20C

11x7E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.66 in/1004.4mb rising, Dew Point: 51.8 F/11C, Humidity 92%

Volts in: 17.742, Amps: 28.06, RPM 9666, Watts in: 497.8

After run temperatures: Motor: 92.7 F/33.7C, ESC 70.0 F/21.1C, Battery 73.8 F/23.2C

12x6E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.80 in/1009.1mb rising, Dew Point: 46.4 F/8C, Humidity 96%

Volts in: 17.546, Amps: 29.32, RPM 9498, Watts in: 514.4

After run temperatures: Motor: 99.2 F/37.3C, ESC 69.1 F/20.6C, Battery 89.1 F/31.7C

13x6.5E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.80 in/1009.1mb steady, Dew Point: 46.4 F/8C, Humidity 94%

Volts in: 16.726, Amps: 36.9, RPM 8688, Watts in: 617.2

After run temperatures: Motor: 104.1 F/40.1C, ESC 73.1 F/22.8C, Battery 77.3 F/25.2C

Pack 2: ambient M1/A123 6S1P 2300mAh

10x7E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.68 in/1005.1mb rising, Dew Point: 51.8 F/11C, Humidity 86%

Volts in: 17.966, Amps: 21.74, RPM 10062, Watts in: 390.6

After run temperatures: Motor: 89.2 F/31.8C, ESC 68.4 F/20.2C, Battery 63.8 F/17.7C

11x7E Ambient Temperature: 63 F/17.2C, Barometric Pressure: 29.69 in/1005.4mb rising, Dew Point: 50.0 F/10C, Humidity 83%

Volts in: 17.45, Amps: 27.16, RPM 9522, Watts in: 473.9

After run temperatures: Motor: 94.0 F/34.4C, ESC 70.2 F/21.2C, Battery 69.1 F/20.6C

12x6E Ambient Temperature: 63 F/17.2C, Barometric Pressure: 29.69 in/1005.4mb rising, Dew Point: 50.0 F/10C, Humidity 83%

Volts in: 17.394, Amps: 28.74, RPM 9414, Watts in: 500.0

After run temperatures: Motor: 92.8 F/33.8C, ESC 70.1 F/21.2C, Battery 69.0 F/20.6C

13x6.5E Ambient Temperature: 63 F/17.2C, Barometric Pressure: 29.69 in/1005.4mb steady, Dew Point: 50.0 F/10C, Humidity 84%

Volts in: 16.578, Amps: 36.6, RPM 8616, Watts in: 606.8

After run temperatures: Motor: 100.6 F/38.1C, ESC 72.3 F/22.4C, Battery 79.0 F/26.1C

Pack 3: ambient Emoli 5S1P 3000mAh

10x7E Ambient Temperature: 64 F/17.8C, Barometric Pressure: 29.70 in/1005.7mb rising, Dew Point: 48.2 F/9C, Humidity 85%

Volts in: 17.392, Amps: 20.54, RPM 9774, Watts in: 357.2

After run temperatures: Motor: 88.3 F/31.3C, ESC 68.6 F/20.3C, Battery 67.4 F/19.7C

11x7E Ambient Temperature: 63 F/17.2C, Barometric Pressure: 29.70 in/1005.7mb rising, Dew Point: 48.2 F/9C, Humidity 85%

Volts in: 16.808, Amps: 25.36, RPM 9228, Watts in: 426.3

After run temperatures: Motor: 94.4 F/34.7C, ESC 70.0 F/21.1C, Battery 69.0 F/20.6C

12x6E Ambient Temperature: 63 F/17.2C, Barometric Pressure: 29.70 in/1005.7mb rising, Dew Point: 50.0 F/10C, Humidity 84%

Volts in: 16.74, Amps: 26.84, RPM 9102, Watts in: 449.3

After run temperatures: Motor: 93.6 F/34.2C, ESC 72.5 F/22.5C, Battery 71.0 F/21.7C

13x6.5E Ambient Temperature: 63 F/17.2C, Barometric Pressure: 29.71 in/1006.1mb rising, Dew Point: 46.4 F/8C, Humidity 83%

Volts in: 15.872, Amps: 33.7, RPM 8304, Watts in: 534.9

After run temperatures: Motor: 102.1 F/348.9C, ESC 75.6 F/24.2C, Battery 80.3 F/26.8C

It is interesting to note that when using the 13x6.5E there is almost 100 watts in difference between the preheated packs and the ambient temperature packs of each type. It seems they all like a little preheating to perform best.

My Recommendations for Using the Tower pro 3520-7

This is the hardest part because Everyone Has His or Her Own Opinion! I prefer not to stress any part of the power system, and the following are what I base my recommendations on.

The motor with leads weighs approximately 262g. When using this motor, I would not use it at less than 400 watts in, or 1.52 watts in per gram of motor weight, as a smaller, lighter motor would be a better choice at that point. The maximum that I would attempt to use this motor at would be about 800 watts in or 3.05 watts in per gram of motor weight. Some folks press this motor well above my recommendation, but I would not do it myself. The manufacturer gives a 45 amp maximum continuous current, I prefer to error on the conservative side and not use more than about 75% to 80% of that, which would be about 33.75 amps to 36 amps. In the tables that follow, the recommendations are based on my opinions. The electronic speed control should be able to handle the maximum static current plus at least 10%. With the manufacturer stating 45 amps, that means an ESC of at least 50 amps or greater and capable of handling the noted voltage.

The tables below were calculated using my personal preference for using this power system and the power is based on Drive Calculator data at sea level and about 70 degrees Fahrenheit. You MUST actually measure your amps and watts in to determine that you are not exceeding the maximums! All battery notations are for the M1 (A123 Cells) NOT Li-Po cells! The ready to fly weight in ounces is based on the prop disk loading for typical sport, advanced sport and expert sport type planes. The wing area (WA) recommendation is based on the cubic wing loading range for each type of plane. The maximum airframe weight is the RTF weight minus the 10.4 oz. (ready to use weight of motor), minus 12.5% of the RTF weight for the radio system, minus the M1 cell pack battery weight. Notice that the maximum airframe weight stays the same for all three types of planes and the wing area determines which type of plane it will be at that weight. The expected watts in are at sea level and about 70 degrees Fahrenheit with an ambient temperature battery. Performance will increase markedly with a "heated" battery. The power range in the tables represents about 125 watts in to 100 watts in per pound.

WA = wing area in sq.in.

NA = not applicable, out of range

Battery 7S1P M1, Recommended starting prop: APC 12x6E, Expected Watts in ~720

| RTF | | Adv. | Expert | Maximum |

| Weight | Sport | Sport | Sport | Airframe Wt. |

| oz. | WA | WA | WA | oz. |

| 94.2 | 642-815 | 539-642 | 451-539 | 52.0 |

| 98.2 | 660-838 | 554-660 | 464-554 | 55.5 |

| 102.1 | NA | 569-678 | 476-569 | 58.9 |

| 106 | NA | 583-695 | 488-583 | 62.4 |

| 110 | NA | 598-712 | 500-598 | 65.9 |

Battery 7S1P M1, Recommended starting prop: APC 11x7E, Expected Watts in ~695

| RTF | | Adv. | Expert | Maximum |

| Weight | Sport | Sport | Sport | Airframe Wt. |

| oz. | WA | WA | WA | oz. |

| 89.1 | NA | 520-619 | 434-520 | 47.6 |

| 92.4 | NA | 532-634 | 445-532 | 56.2 |

Battery 6S1P M1, Recommended starting prop: APC 13x6 sport, Expected Watts in ~588

| RTF | | Adv. | Expert | Maximum |

| Weight | Sport | Sport | Sport | Airframe Wt. |

| oz. | WA | WA | WA | oz. |

| 78.3 | 568-720 | 477-568 | 399-477 | 41.0 |

| 83.0 | 590-749 | 496-590 | 414-496 | 45.1 |

| 87.6 | 612-776 | 514-612 | 430-514 | 49.2 |

| 92.2 | 633-803 | 532-633 | 445-532 | 53.2 |

Battery 6S1P M1, Recommended starting prop: APC 12x8 sport, Expected Watts in ~609

| RTF | | Adv. | Expert | Maximum |

| Weight | Sport | Sport | Sport | Airframe Wt. |

| oz. | WA | WA | WA | oz. |

| 78.5 | 569-721 | 478-569 | 399-478 | 41.2 |

| 82.5 | 588-746 | 494-588 | 413-494 | 44.7 |

| 86.4 | 606-769 | 509-606 | 426-509 | 48.1 |

| 90.3 | 624-792 | 524-624 | 438-524 | 51.5 |

| 94.2 | 642-815 | 539-642 | 451-539 | 54.9 |

Battery 6S1P M1, Recommended starting prop: APC 11x8.5E Expected Watts in ~553

| RTF | | Adv. | Expert | Maximum |

| Weight | Sport | Sport | Sport | Airframe Wt. |

| oz. | WA | WA | WA | oz. |

| 72.6 | 540-685 | 453-540 | 379-453 | 36.0 |

| 75.9 | 556-705 | 467-556 | 390-467 | 38.9 |

| 79.2 | 572-726 | 480-572 | 402-480 | 41.8 |

| 82.5 | 588-746 | 494-588 | 413-494 | 44.7 |

| 85.8 | NA | 507-604 | 424-507 | 47.6 |

Battery 6S1P M1, Recommended starting prop: APC 10x9 sport, Expected Watts in ~480

| RTF | | Adv. | Expert | Maximum |

| Weight | Sport | Sport | Sport | Airframe Wt. |

| oz. | WA | WA | WA | oz. |

| 62.7 | 490-630 | 411-490 | 344-411 | 27.4 |

| 65.4 | 504-639 | 423-504 | 354-423 | 29.7 |

| 68.2 | 518-657 | 435-518 | 364-435 | 32.2 |

| 70.9 | NA | 446-531 | 373-446 | 34.5 |

| 73.6 | NA | 457-545 | 383-457 | 36.9 |

| 76.4 | NA | 469-559 | 392-469 | 39.4 |

Battery 5S1P M1, Recommended starting prop: APC 14x7E, Expected Watts in ~502

| RTF | | Adv. | Expert | Maximum |

| Weight | Sport | Sport | Sport | Airframe Wt. |

| oz. | WA | WA | WA | oz. |

| 64.1 | 497-630 | 417-497 | 349-417 | 31.4 |

| 69.5 | 524-665 | 440-524 | 368-440 | 36.2 |

| 74.8 | 551-699 | 462-551 | 387-462 | 40.8 |

| 80.2 | 577-732 | 484-577 | 405-484 | 45.5 |

Battery 5S1P M1, Recommended starting prop: APC 13x8 sport, Expected Watts in ~469

| RTF | | Adv. | Expert | Maximum |

| Weight | Sport | Sport | Sport | Airframe Wt. |

| oz. | WA | WA | WA | oz. |

| 59.9 | 475-602 | 399-475 | 333-399 | 27.8 |

| 64.5 | 499-633 | 419-499 | 350-419 | 31.8 |

| 69.1 | 522-663 | 439-522 | 367-439 | 35.8 |

| 73.7 | 545-692 | 458-545 | 383-458 | 39.8 |

Battery 5S1P M1, Recommended starting prop: APC 12x10E, Expected Watts in ~503

| RTF | | Adv. | Expert | Maximum |

| Weight | Sport | Sport | Sport | Airframe Wt. |

| oz. | WA | WA | WA | oz. |

| 66.8 | 511-648 | 429-511 | 359-429 | 33.8 |

| 70.7 | 530-673 | 445-530 | 372-445 | 37.2 |

| 74.6 | 550-697 | 462-550 | 399-462 | 40.6 |

| 78.5 | 569-721 | 478-569 | 399-478 | 44.0 |

Battery 5S1P M1, Recommended starting prop: APC 14x10 sport, Expected Watts in ~401

| RTF | | Adv. | Expert | Maximum |

| Weight | Sport | Sport | Sport | Airframe Wt. |

| oz. | WA | WA | WA | oz. |

| 53.5 | 440-559 | 370-440 | NA | 25.0 |

| 58.8 | 469-595 | 394-469 | 329-394 | 29.7 |

| 64.1 | 497-630 | 417-497 | 349-417 | 34.3 |

That is a HUGE amount of information.

How do you use it?

Example 1:

I was thinking of possibly using this motor in a 540/550 sq.in. sport scale ARF AT-6. I was able to get the majority of the airframe weight on the Internet (RC Groups) and found that the out of the box airframe weights totaled 52.5 oz. I figured another 10% of that weight should give a pretty close estimate to actual completed airframe weight. That would be about 58 oz. for the completed airframe weight, which also includes things like the propeller, pushrods, control horns, glue, etc. A 58 oz. or higher airframe weight is only found in the table using a 7S1P M1 pack and a 12x8E prop. With a wing area of 550 sq.in., it falls into the expert sport group. That was not exactly the type of plane I was hoping for. Another consideration was that I only have a 6S1P M1 pack at this time.

Since it is summer, I want to get this power system in the air to play with as soon as possible.

Example 2:

I have an airframe that is not in use now. It is my TigerShark low-wing sport plane with the radio still installed. The completed airframe weighs about 22 oz. and has 488 sq.in. of wing area. From the tables above, it can be seen that using my 6S1P pack an APC 10x9 sport prop might be the way to go. At 480 watts in, it could really liven up the performance compared to the original power system, which used an Astro Flight, geared 035 cobalt brushed motor and 10 Sanyo RC1700 Ni-cad cells.

Example 3:

I have the wing and tail-feathers for my ill-fated Sportsman Aviation Sport Stik 40 ARF Low Wing Aircraft. I could build another new fuselage for it. The first fuselage was destroyed by not selecting the correct model on my Hitec Eclipse 7 transmitter. The second fuselage was destroyed with a battery/switch connector failure. It has about 585 sq.in. of wing area. The original had a completed airframe weight of 50 ounces and with the 5S1P True RC Li-Po, essentially the same weight as my 6S1P M1 pack, it weighed 84 ounces. Using the tables above it can be seen that an APC 13x6 sport or APC 12x8 sport prop might be the ones to start with.

Example 4:

This motor was originally purchased to go in my scratch built, self-designed Vultee BT-13. My design target is about 540 sq.in. (1/8-scale) and a maximum RTF weight of 94 oz. that being a CWL of 13 oz./cu.ft., the highest advanced sport type, with the target weight being about 10 oz. less putting it in the mid-advanced sport range. Using these numbers, it can be seen that it is similar to the Sport Stik except for using a higher CWL.

Ken, Why All the Numbers That Confuse Us?

Picking a suitable power system involves many factors and variables. It can be seen from my examples and the tables that this motor, with various power supplies, can be used in many ways. This is always a problem for everyone selecting a power system.

Why M1 Cells?

For sport and sport scale planes, I strongly believe that M1 cells are the way to go. For those of you who don't want to make your own packs, Michael Charles, www.bigerc.com once again has packs available.

Kv

Kv is a motor constant and is directly related to Kt, the motor torque constant. Kv is most often expressed as RPM/Volt or RPM/v. Kt is often expressed in the units inch ounces per amp. Kv (expressed as RPM/v) * Kt = 1352.4. The Kv motor constant has nothing to do with the applied voltage. It is part of the motor's physical makeup.

Kv is also known as the generator constant or dynamo constant. When any electric motor is spun physically it generates electricty. It doesn't matter whether it is a brushed or brushless motor.

A typical hobby brushed motor can be spun by a drill press at a constant speed. By measuring the DC voltage across the terminals, with brushes set to neutral timing, and knowing the RPM of the drill press the Kv can be calculated. i.e. 1560 RPM / 1.6v DC measured volts = 975 RPM per volt.

A brushless motor isn't quite as simple to do, but can be done using some math. A brushless motor has three possible lead combinations that need to be measured using AC voltage. i.e. Know the RPM (1560 in this example). Measure the AC voltage on each pair of leads, there are three possible combinations with a brushless motor. Lead combination A - 2.08, Lead combination B - 2.08, Lead combination C - 2.08. Note that most cheap motors do not have all three combinations come out exactly the same, but they do on the better quality motors. Use the average of the three voltage numbers if the measurements are slightly different.

Find the V-peak by multiplying the average AC volts by 1.414 In this example 2.08 * 1.414 = 2.94v

Divide 1000 (a constant) by the RPM (1560 in this case) = 0.64

Ke = V-peak ((2.94) * (in this case 0.64))/1000 = 0.00188

Find the inverse of Ke (1/Ke) (1/0.00188 in this case) = 531

Divide the inverse of Ke by 0.95 = 559 RPM/v or the approximate Kv expressed as RPM/v

It should be noted that many manufacturers/suppliers, even the good ones, provide inaccurate information on the motor's Kv, so if you can, measure it to be sure you have the motor you want. Nothing really needs to be done to the motor to measure the Kv, so it should be easily returnable if the Kv is not suitable, as the shaft will only have been chucked into a drill press that is set up with a known RPM.

Advancing the timing on a brushed motor (using rotation of the brushes) or brushless motor (via an ESC setting) changes the apparent Kv, increases the RPM and Io (no load amp draw), increases the heat (wasted energy) more than neutral timing, but increases the power out.

Return to article

To Reach Ken Myers, you can land mail to the address at the top of the page. My E-mail

address is:

KMyersEFO@mac.com

EFO WEBsite: http://members.aol.com/KMyersEFO/

|