The Nitty Gritty

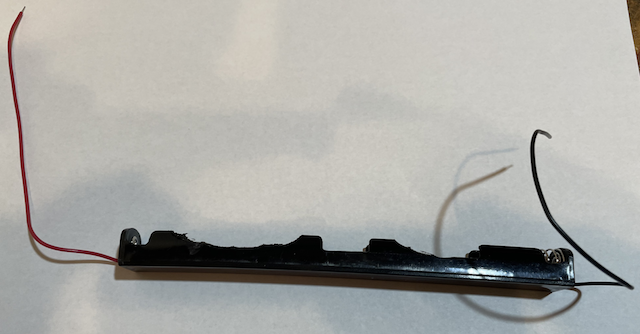

The photo shows that the center "wings" of a 3 battery battery box only needs a slight modification on each center side. There must be some of the two center "wings" to hold the center battery in place and keep it from "popping out". Button top 14500s just barely work in this 3 battery battery box but IMR 14500 flat top batteries would be a better fit. Three Efest IMR 14500 size 650 mAh batteries were charged using the MC3000 to 4.2V at 0.33A (an approximate 0.5C charge rate). They were rested for three hours to allow them to reach a stabilized resting voltage before being discharged. The batteries were discharged at 0.3A to 3.4V for a preliminary capacity test. I previously found that 0.3A is the approximate average amp draw when running my Walthers Trainline GP15-1 diesel locomotives using LocoFi™ in the locomotive and a 3S resultant 10440 size (AAA) IMR battery in a battery car. I used 0.3A for the discharge current draw based on that previous experience. After a lot of testing, a 3.4V, under load, cut off was used to allow Lithium Nickel Manganese Cobalt Oxide (INR/NMC) batteries to be used as well as Lithium Manganese Oxide (IMR) batteries that were tested here. All three batteries started the discharge at 4.17V open circuit volts. The screen captures show the mAh removed from each battery down to 3.4V at 0.3A for an average of 642mAh removed. That is very close to the labeled capacity of 650mAh. That also indicates that the batteries were, for all practical purposes, empty. The highest mAh discharged was 646mAh. It took approximately 2 hours. By the time I made the screen captures it was showing about 2 hours and nine minutes because the MC3000 was reporting the current voltage value at the time of the screen capture, but the actual discharge time was closer to 2 hours. Because there was not time left in the day, to do a Prototypical Run Time Test, the batteries were rested over night. The following morning, the three batteries were charged using the MC3000 to 4.2V at 0.33A (an approximate 0.5C charge rate). The iPhone screen captures show the returned mAh after the discharge test. An average of 662mAh was returned. Note that the returned, reported mAh is higher than the battery's labeled capacity of 650mAh. The average discharged capacity was 642mAh. The reason for this seeming anomaly is explained in the section titled, "Summary of How a Good Lithium-ion Charger Works". The returned mAh numbers indicate that a bit more than 3% was returned to the battery than was taken out. Once the charger reaches the constant voltage stage, the battery continues to absorb charge as the current is reduced to a predetermined TERMINATION current cut off. The TERMINATION current used here was 0.04A. That is a little over 10% of the charge current of 0.33A. 0.4A was defaulted by the MC3000 charger. Once the batteries were charged, the CSX, with the gondola battery car, was Configured in the LocoFi™ App using seven steps. Before running the seven step configuration, the loco and battery car combination was "warmed up" with two loops on the 16' 3" main loop of the demo layout. The LocoFi™ App uses the tens and ones place, and optionally a decimal point, followed by a single digit in the tenths place with a fixed letter V following the input box; ie. 12.5 V. The digit 1 was input in the tens place, the digit 2 was input in the ones place, the decimal point was chosen and the digit 5 was input in the tenths place. That is the Configuration's saved naming convention. I arbitrarily named the new profile 12.1 V. I named it 12.1 as 10, 12 and 13 had already been used and saved for this locomotive. The configuration only sets the seven speed steps to the voltage being used for the calibration in the configuration. That works well when a constant DC power supply to the track is used, but with the ever changing voltage of the batteries during use, it is not as accurate, but I still do it. The step 7 configuration showed a top speed of 69 mph. The full scale GP15-1 has a top speed of 65 mph, so the maximum speed was set to 65 mph in the App. The batteries were recharge after the configuration run. When I did the Prototypical Run Time Test using four 10440 size Lithium Iron Phosphate batteries and three 10440 size Lithium Manganese Oxide batteries, I used 15 minutes of prototypical running followed by a break, usually of 10 minutes, and then another 15 minutes of run time. I did that three times, as both types of resultant battery packs produced 45 minutes of prototypical run time. With the relatively high discharge test mAh values for the three Lithium Manganese Oxide 14500 size 650mAh batteries, compared to the IMR 10440 size 350mAh batteries, I knew this was going to be a LONG session to reach 3.4V under load to stop the testing for the Prototypical Run Time. I decided to do 20 minutes of prototypical running, followed by at least a 10 minute break and to not start measuring the "as close to loaded voltage as possible" until the end of the first hour of running. Because the batteries were so difficult to remove from the battery box, I didn't take out a battery to measure its "as close as possible to loaded volts". I measured the total voltage of the 3S resultant battery and divided by three to get the "as close as possible to loaded volts" average. 60 minutes 11.23V Resultant 3S battery / 3 batteries = a 3.74V average

I stopped at two hours, as that is what the "experts", creating Dead Rail/Battery on Board commercial systems, had noted that they were targeting for battery run time. (see "How Long Is a Typical Operating Session's Run Time?") The following morning the three batteries used, for the Prototypical Run Time Test, had an open circuit voltage of 3.60V. They were recharged to full using the MC3000 charger. An average of 536mAh was returned to the three batteries. This discharge data, along with the open circuit voltage of 3.6V, indicated that the batteries had not been too deeply discharged while running for a total of two hours, using 20 minutes of run time followed by some rest/break periods, on my flat demo layout, with only three cars available to be switched and/or pulled as a train by the locomotive with its attached battery car. Before storing the 3 IMR 650mAh batteries, they were "storage discharged" to about 3.8V using the MC3000 charger/discharger. |