|

The New Procedure for Checking the Magnetic Uncouplers

1. Check, using the Kadee Coupler Height Gauge, to see that the locomotive(s) and their battery car(s) are at the correct height. (They were.)

2. Select three cars to use to check the uncoupler magnets, not a whole train. Check those cars for the correct height using the Coupler Height Gauge. Adjust those cars as necessary to match the Kadee Height Gauge. (The Southern Pacific 40' boxcar was correct but both the 40' GT boxcar and 50' C&O boxcar required another red, Kadee 0.015" washer1. They already had one under each bolster, but they were too low.)

3. Use the three cars to manually test each magnet uncoupler in each direction. Practice uncoupling with each magnetic uncoupler. If the car being uncoupled rolls even a little bit, re-level the area where the magnet uncoupler is. Move the uncoupler, if necessary to get a straight run into it. Check that the Kadee coupler moves very freely in its gearbox.

4. Create a train consisting of the locomotive (Conrail in this instance), with its battery car, and the three cars that were used to manually check each magnet uncoupler. Run that train and check out each uncoupler. If problems are found, correct them. (The magnets, for the spur on the south side of the dogbone and the spur on the north side three parallel tracks, had to be relocated.)

5. Set the three cars aside once everything appears to be working correctly.

6. After checking coupler height and adjusting if necessary (It wasn't necessary), shunt the remaining cars to all of the spurs from both directions (I had six). (I used the second locomotive (CSX locomotive in this instance), with its battery car to do this.)

7. Fix any problems. Problems can be as simple as loosening the coupler gearbox screw a little to allow the coupler to swing more freely, which is an easy fix, up to removing, repositioning and leveling the magnetic uncoupler.

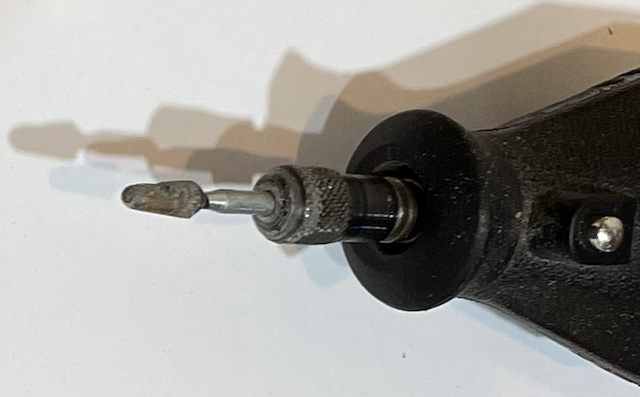

Footnote #1. The hole in the Kadee washer was not large enough to slip over the screw bolsters in the Walthers 50' and 40' boxcars. The washers were reamed out using a Dremel tool and the bit shown in the photo.

|