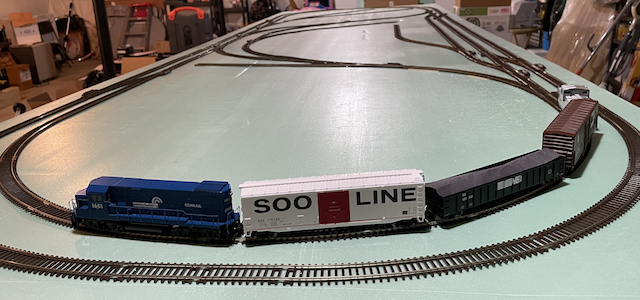

After carefully checking the trackwork for misaligned rail joiners for the last time, the track was pinned to the foam insulation board using straight pins. Four Soshine LiFePO4 batteries were charged using a SkyRC MC3000 charger. The Galaxy S7 Edge Android phone was also charged. (Please see the updated page on sourcing batteries.) The train, consisting of the Walthers' CSX GP15-1 LocoFi™ equipped locomotive, gondola battery car, Soo Line 50' Boxcar, Conrail 50' boxcar and CSX caboose were set up on the outside loop. All the turnouts were checked for the correct throw position. With the charged batteries in place in the battery car, the LocoFi™ App was started on the Galaxy S7 Edge. Once the phone and the LocoFi™ sound and control module were connected via WiFi, the locomotive was started for its first run on the layout. The first run around the outside loop was at 25 scale mph. A 50 mph top speed was also tried. All sections of track were tried in all directions. There were 21 Atlas 18" radius turnouts, now 23 turnouts, on the layout at that time, and "right out of the box", only three seemed to cause any kind of a problem. Unfortunately, this was not true. See below. The train was run for 45 minutes, which is what I believed to be the prototypical run time limit of the 280mAh batteries at that time. Since then, I have discovered that both the 4 LiFePO4 10400 size and 3 Lithium Manganese Oxide 10400 size can be safely used for one hour of prototypical run time. Overall, everything went well, finally! With the layout almost ready to run trains, seven pieces of rolling stock were ordered on December 7, 2022 from Yankee Dabbler. The new rolling stock was to be used to create two trains to run simultaneously and to create longer trains. The rolling stock arrived on Thursday, December 15, 2022 by USPS Priority 2-Day Mail. Since the battery car gondola seemed to be the one most affected with derailments, the easy fix was tried first. The leading truck on the gondola, closest to the locomotive, was rotated 180 degrees. That did not fix the derailment issue. Even though the track had been checked repeatedly, over several days, there was a misaligned rail joiner between two switches between the outer and inner loops. It was corrected and the issue was taken care of at that spot. The other two problematic turnouts both had the same problem. They both transitioned from a straight section to a turnout. They both had a visible "dip", when using a flat straight edge, between the straight section and the turnout. Both areas were shimmed with balsa, and that appeared to remedy the problems in both areas.

Blue painter's tape flags were placed to identify problematic areas when they originally showed up. What caused the "dip" was not really apparent. It could be a bit of a void, caused by the rippling seen on the top of the foam insulation board, or something else that was not easily detected. Once all of the track-work appeared to be "fixed", the train was run repeatedly through the problem areas. For a second test, the train was run, very successfully, in reverse, at somewhat high speed through all of the track-work. Next, the Walther's Conrail GP15-1 was set up as the locomotive with the Soo Line Boxcar as the battery car. The gondola, with spare batteries as weight, came next and was followed by the Conrail boxcar and then the C&O caboose. The first time the Conrail came to an 18" radius curve, it stopped. The "J" trip pin part of the Conrail's front coupler was caught against the outside rail of the curve and stopped the locomotive from moving forward. Needle-nose pliers were used to "adjust" the "J" upwards. That eliminated the problem.

The Conrail headed train ran well in both forward and reverse through all the sections of track. About a month later, an out of the box Atlas Code 83 18" was found to be defective while trying to switch cars around on the "Y" spur. Note the smooth curve on the outside diverging switch rail.

I replaced the turnout on the inner loop going into the "Y" spur with the one used at the "V" part of the "Y" and then purchased a new turnout at Nankin Hobby for the "V" part of the "Y" spur.

Replacing the turnout fixed the problem in that area. |