Because of an oops I had with the drive shaft components on the rear truck of the CSX, the same locomotive was purchased with Conrail markings. The same modifications were done to the Conrail, as it was to become the Li-Po conversion replacement, but they were really unnecessary when it was decided to use a battery car instead of fitting a small Li-Po in the body shell. Only two modifications would have been required for the Conrail with its battery car.  Both modifications can be seen in this photo of the Conrail shell. A portion of the rear, right screw holder part of the body shell needed to be removed so that the power leads could feed through the screw hole in the frame. A hole had to be drilled in the shell to allow the power leads to exit the rear toward the battery car. The same modifications were completed on the CSX shell to convert it to use a battery car. Since the gray box had been removed already, I measured and it looks like the decoder and speaker can be secured to the inside top of the shell without interference from the gray box. 02/12/23: A third Walthers Trainline GP15-1, in Conrail livery, was purchased and the LocoFi™ Decoder and attached Speaker do fit without removing the gray box over the rear truck. Its biggest problem was that the CSX Li-Po battery conversion used a non-circuit protected Li-Po, which is probably the least safe Lithium-ion type battery, as it requires a lot of user knowledge of safe handling practices, charging, chargers, dischargers, special voltage meters and safe storage practices. A more practical conversion to Dead Rail, using LocoFi™, was to use three 10440 Efest IMR 10440 V1 350mAh High Discharge Flat Top batteries in a trailing "battery car". These batteries are no longer available. Either the 10440 Efest IMR10440 V1 350mAh High Discharge Flat Top batteries or the 10440 Efest IMR10440 V2 350mAh High Discharge Button Top can be used. These batteries are no longer available. I used the flat top batteries, but actually prefer the button top when using the SkyRC MC3000 charger. This is a good conversion, and it is relatively safe, but I now prefer to use four Lithium Iron Phosphate 10440 size batteries, instead of 3 IMR batteries. How to do this is shown in another section of this article.

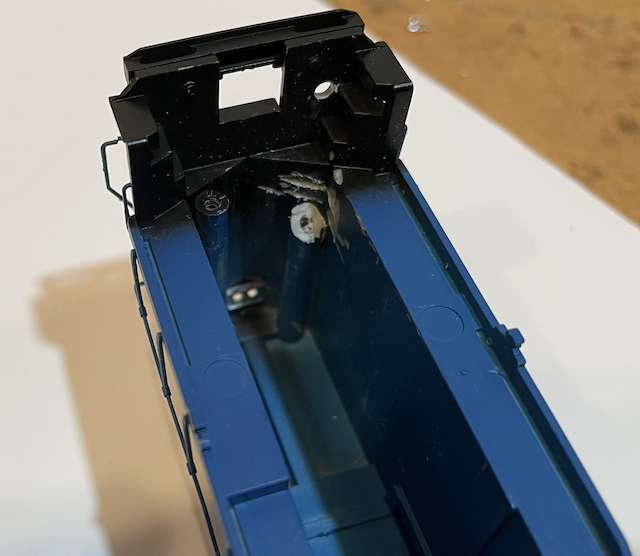

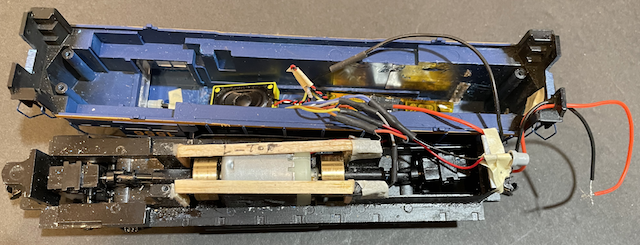

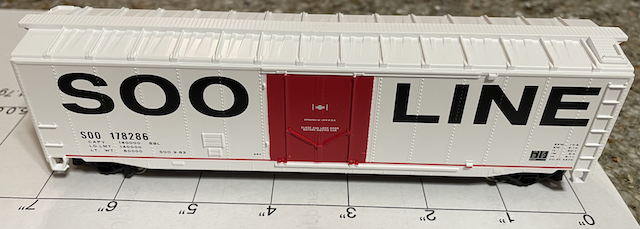

The LocoFi™ decoder and speaker were removed and the connector for the Li-Po battery removed. The right, rear screw portion of the body shell was removed to allow the power leads to pass through the right, rear screw hole in the frame. A hole was placed in the rear of the body shell for the power leads to pass out through. Eight inches of red and black 30AWG wire were threaded through the bottom of the screw hole in the frame, pulled up and then soldered to the red and black power leads of the decoder.  The decoder and speaker were secured to the inside top of the body shell and the shell placed on the frame while working the red and black leads out of the screw hole and through the hole in the rear of the shell.  It was a bit fiddly, but not too bad with patients and some tweezers. A boxcar was ordered through Amazon, as I wanted to see if it would work as well as the gondola that is the battery car for the Conrail. Boxcar Data

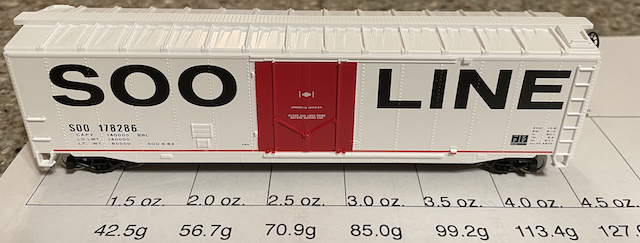

Length: 7" Delivered Weight: 96.9g or 3.42 oz.  NMRA Recommended Wt.: 127.6g or 4.5 oz. Battery Boxes with 4 10440 batteries: 49.6g or 1.75 oz. (Only 3 are in the battery circuit, and the 4th, at that time, was used for balance.) The flat metal weight provided inside boxcar as received: 27.1g or 0.96 oz. Weight of box car with batteries battery boxes and 4 batteries installed and the inside weight removed: 119.4g or 4.2 oz. A 7g or 1/4 oz. weight was added to the center floor of the frame to get the weight closer to the NMRA Recommendation. Total running weight: 4.45 oz.  The boxcar shell was carefully removed from the frame using a small, flat blade screwdriver. The weight was removed. Some cross molding was removed from the top, inside of the frame to allow the battery boxes to set flat. Before sanding the sides of the frame so that the boxcar shell would just slip over it, I tried to remove the trucks and couplers. The trucks could not be removed because they screw into an unsecured "pin" that goes through the frame to the underside. A little baking soda was applied to the top of the pins with a brush and then thin CA glue was applied. That stopped a lot of the wabble that the boxcar originally had. The car's frame was tested on the layout by shoving it all around, and the secured pin didn't cause any derailment problems, but much of the wabble was gone. The outside of both sides of the frame were sanded and the front and rear corners of the frame rounded until the shell would slip easily on and off the frame.  Two other modifications were needed. A slot had to be made in the boxcar shell's front end for the power leads to pass through.  1/32" by 1/8" strips of balsa wood were added, along the molded line seen in the boxcar, on both sides, to keep the boxcar body shell from slipping down too far and interfering with the trucks.  The "wings" were removed from the battery boxes. 02/12/23: With no batteries in the battery boxes, the front red lead was soldered to the rear box's black lead. Pins from a Micro-Mark 32-pin Micro Connector Set are used on the two remaining, unconnected, red and black leads. Those connectors connect to the same type connectors on the red and black power leads from the decoder in the locomotive. A connector in the shape of an AAA battery is used in one slot so that the 3 IMR batteries create a 3S (3 in series) battery. The battery boxes were secured to the boxcar frame using folded masking tape. Like the Conrail conversion, there is no switch. Removing a battery breaks the circuit and putting it back in turns the circuit on again.  Once the sides of the frame have been sanded correctly, the shell just slips right on and off. The locomotive, with its boxcar battery car, was run over all of the track sections on the demo layout and showed no problems with any type of derailments. Both locomotives, the CSX and Conrail can be run prototypically on the flat demo layout for 60 minutes each. To view both 3S 10440 conversions running together, view this part of the Part 6 video on YouTube. |