My Revolextrix Gt500 Follow-up

http://theampeer.org/ampeer/ampjan17/ampjan17.htm#GT500

A Very Good Charger for Your 12V Field Battery

My somewhat 'expensive' system is serving me well, but I am always on the look out for 'things' to recommend for those new to the hobby, especially if they don't cost an 'arm and a leg'.

* * * * *

I recently became aware of this charger and power supply combo from Hitec. I thought I'd give it a try. It is not a lot more money than the typical 50W-80W four button AC/DC chargers, usually purchased by beginners, and it appears to be a lot more capable at up to 180W of charging power.

I ordered the $79.99 combo through Tower Hobbies on Nov. 11, 2017. It was back ordered. It arrived on December 11.

As usual, I researched it online.

I downloaded the manual for the charger and manual for the power supply from the Hitec Web site.

I also downloaded the manual for the SkyRC RS16 charger and manual for the SkyRC power supply.

Someone at Hitec did a great job rewriting the SkyRC charger manual! The Hitec version is much clearer and has some very appropriate warnings about using the charger that are not in the SkyRC versions of the manual.

Unfortunately, there was one somewhat misleading statement in the INTRODUCTION section of the Hitec manual, p. 3. It states, "Capable of charging all battery types including Lithium, NiCd/NiMH and Lead-Acid chemistries with a tremendous 230-watt charge amperage rate..."

The specifications on the power supply itself notes, "230 WATT" while the charger specifications note, "Charger Circuit Power 180 Watts", p. 11. Also, it is not an "amperage rate".

I watched the very few videos, on YouTube, regarding the Hitec X1 Pro and SkyRC RS-16. The videos, that I did find in English, had some comments that were incorrect regarding this charging system.

The videos demonstrated the relative size, how to move through the menus and a few of the features.

The Hitec X1 PRO Charger

Even though it has been around awhile, before this review I was unaware of it. Maybe I never looked at it before, because the 'original' price was almost double the price it is selling for today.

I found a review of it posted in August of 2014 at BigSquidRC.

All of the specifications can be found online.

The most relevant specifications are; 16 amps, 180 Watts.

180 Watts.

180W / 16A = 11.25V

That voltage is not high enough to charge a a standard 3S LiPo at 16 amps, but it could charge a 2S standard LiPo (8.4V) at 16A.

180W / 12.6V (full charge voltage of a standard 3S LiPo) = 14.28 amps

180W / 16.8V (full charge voltage of a standard 4S LiPo) = 10.71 amps

180W / 21.0V (full charge voltage of a standard 5S LiPo) = 8.57 amps

180W / 25.2V (full charge voltage of a standard 6S LiPo) = 7.14 amps

All chargers are rated like that. The noted maximum current is only for a low cell count, low charge termination voltage/maximum charge voltage, battery.

For comparison, the Revolectrix Gt500 is rated at 250W and 20A with a '12V' input.

250W / 20A = 12.5V

The SkyRC iMax B6AC+ AC Balance Charger ($48) is typical of the type of chargers my students purchase on their own. It is rated at 50W with a 5 amp maximum.

50W / 5A = 10.0V

I could tell from the online video that the charger was relatively small, yet opening the charger box proved to still be a surprise. It is really small, 3.6" x 4.4" x 2.0".

The photo shows my Gt500, which isn't large at all, with the X1 Pro, its accessories and an 8" ruler.

While setting up for the photo of the X1 PRO compared to the Gt500, I realized how small the 18AWG wire used on the charging cable is. Page 10 notes, &uqot;18AWG Wire Charging Cable". This cable is used for the charging cable from the charger to the battery's power lead. The photo, p. 10, clearly shows the cable to be short. It is about 6.5" long including the length of the banana connectors. The wire length between the connectors is 3.5".

To begin using and testing the charger, I put Anderson Power Poles (APP) on the 18AWG Wire Charging Cable.

I clipped the DC Input Power Cable in half and added Anderson Power Poles (APPs) to the clipped ends. I use APP connectors on my alligator clips from my Marine/RV battery to the charger. If another power supply is ever used with this charger, I wanted to keep the banana plug option available.

The Power Cable half, with the banana plugs on it and the APPs, can also be used as a heavier duty 'battery' charging cable.

I read through the well written manual one more time.

With no power applied to the charge, I plugged the XT-60 DC Input Power Cable into its socket. I plugged the 18AWG Wire Charging Cable into its banana plug sockets. I plugged the Balance Adapter into the Balance Board and then into the Balance Socket, which is a 6S JST-XH. connector.

Page 16 of the manual has a VERY IMPORTANT NOTE about plugging in the Balance Adaptor to the charger. "The balance wire attached to the battery must be connected to the charger with the black wire aligned with the negative symbol (-)."

It is possible to hook up the 'wrong end' of the Balance Adapter. I know. Don't ask.

Unfortunately, when I plugged in the charger it didn’t work. It just showed a line of boxes going across the screen.

I called Hitec/RCD and got a very positive response. I thought I'd have to send both units back through Tower Hobbies. Mike Mayberry said he'd just exchange the charger, as the power supply appeared to work. We made the arrangement for Hitec to send out the replacement charger on 12/12/2017.

The replacement charger arrived on 12/15/17 by 2 Day Priority Mail. A prepaid return mailing slip was included.

That is what I call SERVICE!!!

I reread the manual again.

On Page 12, Optimized Operating Software, it notes, "The X1 Pro "AUTO" feature sets the charge and discharge current for you automatically, preventing overcharging which can damage your battery."

What it doesn't note is that this feature only applies to NiCd/NiMN batteries, p. 30. A person using Lithium based batteries could be confused.

Actually a lot of the charger's features are for NiCd/NiMH batteries that are still in use by many 'car guys'.

On p. 35, Pb CHARGE MODES, it reads, "The X1 Pro offers the following NiCd/NiMH charge modes: Charge and Discharge." It should read, "The X1 Pro offers the following Pb charge modes: Charge and Discharge."

Unfortunately the explanations are not very clear for the System Setup starting on p. 42. The System Setup found in the SkyRC manual is a bit clearer, but not much better.

It appears that the majority of System Setup changes relate to charging NiCd/NiMH type cells and peak detection for NiCd/NiMH cells.

First I set up the 'new' charger on its companion power supply using the provided "double-sided" banana plug connectors between the power supply top banana sockets, which was unplugged from the AC and off, and the charger’s bottom sockets. No adapters or leads were plugged into the charger.

The power supply was plugged in and then turned on.

The easy to read, blue, LCD screen, with white characters, lit up.

I used the printed manual to remind me how to navigate the various menus. Trying to read the printed manual also reminded me how very poor my vision is. Thank goodness I had a magnifying glass at hand.

The power supply was then shut down. There is no On/Off switch on the charger. The Balance Adaptor cable and Balancing Board were connected correctly to the charger following the information on p. 16 of the manual. The banana plugs of the 18AWG Wire Charging Cable, with APP connectors at the other end, were plugged into their correct sockets of the Charging Output.

The menu was easily navigated to LI BATT METER. A 3S 1000mAh standard LiPo pack was plugged into the Charging Cable and its JST-XH balance connector into the appropriate socket on the Balancing Board. The 'stick' was pushed to the right and voltages for each cell, 3.80V each, showed up on screen. Pushing the 'stick' forward showed the pack voltage of 11.41V and the high (H) cell at 3.806V and low (L) cell at 3.805V.

Next a 4S 1100mAh A123 (LiFe) pack was attached. The voltages were 3.47V, 3.47V, 3.47V, 3.46V, pack voltage 13.88V, H 3.472V, and L 3.464V.

The same 3S 1000mAh LiPo was put into LiPo BALANCE mode at 2 amps (2C) following the directions on p. 20 of the Hitec manual.

During this charge, I accidentally stopped charger. While it was charging, I pressed the 'stick' up to note the individual cell voltages. Instead of pressing right to return to the main charger screen, I pressed the 'stick' down. A lot of interesting information was displayed. I should have pressed the 'stick' right to get out of that information, but pressed left and stopped the charger after about 8 minutes.

I restarted the charger. It took about 18 minutes more to complete the charge. That was a total of about 26 minutes.

Since the pack was not going to be used, I did a storage 'charge/discharge'. This was a discharge to storage voltage, since the pack was "full".

The specifications note that the discharge power is 30W. 30W / 12.6V = 2.381 amps. I set the amps to 2.3A. The charger only allows amp input to the tenths place. The target storage voltage cannot be set.

Shortly after starting the storage process, the fan came on.

The charger stopped after 7 minutes and 39 seconds. It noted 11.38V as the terminated voltage. The individual voltages were not available on the FINISHED screen.

The table on p. 7 of the manual indicates that LiPo Storage Voltage is 3.8V per cell. The SkyRC manual, p. 19 notes, "3.85V for LiPo".

My repeated testing indicated that the charger software tried to terminate the discharge at 11.40V for a 3S LiPo pack. That is 3.8V per cell.

NiCd/NiMH Charging

Next I wanted to check the NiCd/NiMH functions. Unfortunately, the only NiMH packs I have are small 4 cell receiver packs in the 800mAh range. They are generally charged at 1/10C rate. That is basically an over night charge on a 'wall wart' charger.

I tried to charge two of these small 'receiver' packs. It didn't go well. They went 'over voltage' without the peak being detected.

I believe my problem was noted in the manual on p. 30 where it says, "Some batteries of low resistance and capacity can lead to higher current in the Auto Charge mode."

I do believe that they made a small error in the statement. I believe they meant high resistance and low capacity.

I can really draw no conclusions about the charger's ability to charge larger capacity NiCd or NiMH packs used as power packs.

Output Ability

To check the charger's output ability, a 6S 2300mAh A123 (LiFe) pack was used.

Because I leave my A123 packs fully charged in their planes, the pack was discharged and allowed to rest over night.

The charger was removed from the mating power supply and attached to an intentionally partially discharged 12V Marine/RV battery.

180W / (3.6V * 6 = 21.6V) = 8.33A

Using the LiFe Balance Mode, the amps were set to 16. Heavy gauge leads were used by using the half of the DC Input Power Cable with banana plugs on one end and APP connectors on the other. I just had no 'faith' in the tiny 18AWG charing cable.

During the constant current (CC) phase of the charge the amps rose to 8.5 and volts to 21.1. That is 179.35W. Impressive.

Charging a Pb (lead acid) Battery

I have never used one of these multi-chemistry charges to charge a Pb battery before, as I never had a power supply. This was a first.

From the recent use, the 12V Marine/RV battery had an open circuit voltage (OCV) of 12.54V.

The charger was reinstalled on the power supply. I left my version the heavier gauge charge chord on. The Pb battery was attached to the charge cable.

The charge terminated with the message "Over Charge Capacity Limit". It appeared to have reached the default the capacity limit of 5000mAh. That limit is found in the Set Up Menu.

Two hours later the battery's OCV was 12.94V.

The charge was started again.

Within two minutes the volts reached 14.40V and the current dropped to 3.5 amps and continued to drop.

The charge terminated with a TIME LIMIT warning at 2 hours (120 minutes). That is the default time set in the Set Up menu.

After an over night rest, I put it back on the charger. Within two minutes the volts reached 14.40V and the current dropped to about 1 amps and moved up and down very slightly through the complete charge.

The charge terminated with a TIME LIMIT warning at 2 hours (120 minutes).

Shortly after the charge terminated, a Fluke multi-meter showed 13.62V.

I decided that I'd had enough of trying to get the charge to terminate on this charger.

I hooked up the battery to my NOCO charger. The NOCO went through its normal start up and within a few minutes it showed a solid green light. A solid green light indicates that it is 100% full.

I have no idea when it reached this state with the X1 Pro, as the charge never terminated. It only ran out of time.

Obviously, the charger can charge a Pb battery, but it is probably not the best option for doing so.

Parallel Charging (Advanced Skill Required)

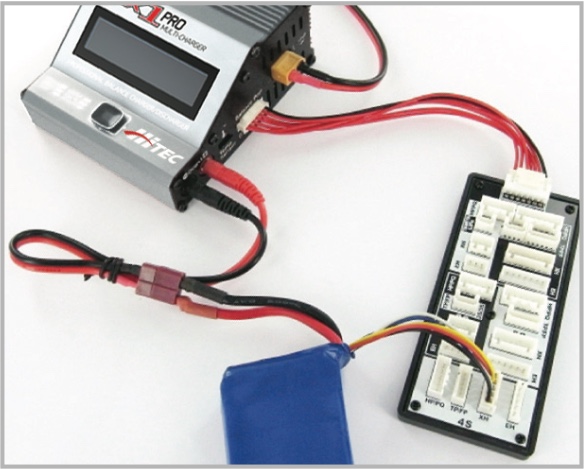

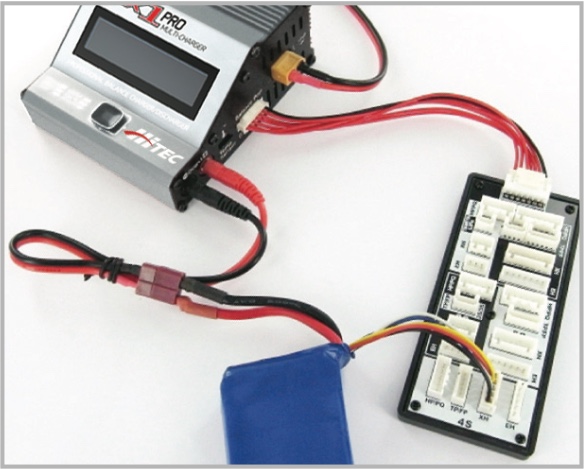

My Buddy RC EP Buddy ParaBoard V2 plugs directly into the JST-XH connector on the side of the charger.

With 180W of power out, this charger can easily parallel change 4 of my 3S 1000mAh LiPo batteries at 1 amps, which is 1C, while at home.

Actually it could charge 180W / 12.6V = 14.29A

14.29A / 4 = 3.57A

Up to four 3500mAh (3.5Ah) packs, charged in parallel, at 1C, which equals 14 amps, and could be handled by this charger.

Beginner's, this is a best buy for you. Grab it while it is still available! Need a second charger? Go for it! :-)

Return to "What's In This Issue"

To Reach Ken Myers, you can land mail to the address at the top of the page. My E-mail

address is:

KMyersEFO@theampeer.org

EFO WEB Site