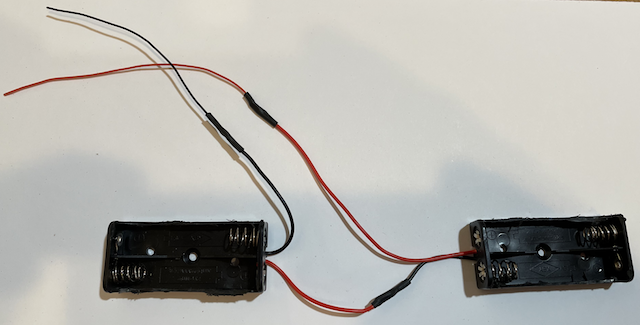

The "wings", that wrap around the top side of the batteries in the boxes, were removed. A Dremel tool was used with a barrel sander, on low speed, to remove the wings. An X-ACTO knife, with #11 blade, was used to clean up the sanding.

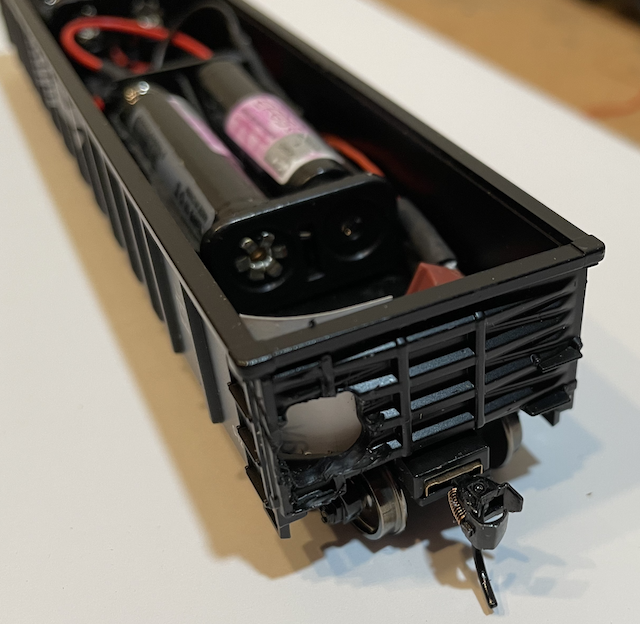

The "De-Winged" box is the lower one in the photo. A pin vice, with a 1/16" bit installed, was used to drill a pilot hole on the right, front side of the gondola and just above the gondola's floor.  The "De-Winged battery boxes were set into position over each truck. A fitment was made to determine the length of the front battery box red wire to the rear battery box's black wire to create a series connection.  The front box's red lead and rear box's black lead were snipped, soldered together and the joint covered with heat-shrink tubing. The other red and black leads were snipped and 30AWG wire soldered on to go through the hole towards the locomotive. Later, a small connector was attached to the red and black 30AWG wire. (In September of 2022 the connector was changed out for two single MicroMark Micro Connectors.) The original battery box configuration using four IMR 10440 size batteries in series was tested with some previously charged cells and the multimeter, set on volts. The resultant 4S battery read 16.42V. (Later it was determined that only 3 IMR 10440 size batteries were needed in series for this application.) Looped masking tape, sticky side out, was used to affix the battery boxes to the gondola floor, once the 30AWG wires had been fed through the front hole. The hole was made too big because I decided not to use those originally chosen connectors. I had "thought" that the small connectors that I had purchased, WST Red Ultra Mini T Plug Connectors Micro T Connector for RC LiPo NiMh Battery Male and Female (10 Pairs), would fit between the locomotive and the "battery car", but they were too large to allow the locomotive and battery car to be coupled together.  A Dremel tool was used to enlarge the hole so that the connectors would both fit into the gondola/battery car. The hole did not have to be that big to use the MicroMark Micro Connectors.  The photo shows the battery car ready for service using 4 IMR 10440 size batteries. (Note that one battery is missing from the fourth slot in the 4S battery box configuration. Removing a battery acts as a "switch".) The photo actually demonstrates the way that 4 10440 size Lithium Iron Phosphate (LiFe) batteries are wired together. Using 4 Lithium Iron Phosphate batteries is the safest method to use, and because of their lower nominal voltage of 3.2V per cell, four are required. It turned out that using 4 IMR 10440 size batteries was a mistake and that only 3 IMR or INR 10440 size should have been used in series. To change the 4 in series number of slots to 3 in series, a fake connector battery is used in one slot, thus leaving only 3 batteries in series. |