Part 2 Unfortunately, only the user can determine the answer to that question. Almost every conversion to Dead Rail, battery power, is unique. There are several factors and variables that make a specific, across the board answer, extremely difficult. How I originally determined the answer to the question is presented, as well as the results for the two conversions that I did in the sections titled "The Procedure to Determine the Actual Run Time Using Three IMR or INR 10440 Size Batteries" and "The Procedure to Determine the Actual Run Time using Four LiFePO4 (LiFe/IFR) 10440 (AAA) Size 280mAh Batteries". The method to determine the prototypical run time is found here. This method is no longer used. This information was left here to provided some basic information regarding Lithium-based batteries with a 4.2V charge termination. * * * * * Part 1 The 3S 300mAh Li-Po battery was fully charged using the GT500 charger and then the locomotive, with a light consist of a gondola, boxcar and caboose was tested, at full speed1, to determine a Derived Run Time2. The LED headlight was also illuminated for the whole test. The test's results provided a worst case scenario of run time. Actual Run Times, during normal, prototypical operations, should be longer.

The procedure used was to run the train for 10 minutes, measure the percentage of usable power left in the pack**, rest the motor for 10 minutes and then repeat the process.

Using the voltage of a Lithium-ion based rechargeable battery, that has a nominal voltage noted as 3.6V/3.7V and a charge termination voltage of 4.2V, is used to determine its state of charge (SOC). This method of determining the SOC is not that accurate, but it is a very common practice. This method, used to determine the approximate SOC, CANNOT be used with other types of Lithium-ion rechargeable batteries, and yes there are some! ***The following SOC percentages were gathered using a device that contains a lookup table based on each individual battery's voltage. 10 minutes 88% left in pack

The procedure used was to run the train for 10 minutes, measure the percentage of usable power left in the pack**, rest the motor for 10 minutes and then repeat the process.

What the user needs

The Procedure

The number of minutes derived from this test IS NOT THE ACTUAL RUN TIME. The test results provide a base number from which to work, or the Derived Run Time. If the layout is fairly level, and the string of cars behind the loco aren't too many, put 5 minutes LESS than the Derived Run Time on a timer and put the locomotive into normal service on the layout. If the layout has several, or steep, elevations and is pulling a lot of cars, it might be a good idea to reduce the derived time by 10 minutes. Once everything is ready to go on the layout, start the timer. Make some runs between points, do some switching, turn the sound and lights off if another loco is working, do whatever is a normal working session for the layout. Stop working the layout when the timer goes off and immediately measure the voltage of a single battery using the same method as was used to arrive at the Derived Run Time. That measured voltage can confirm whether the tested Derived Run Time is the Actual Run Time of the battery for this layout, too long, or whether there is enough capacity in the pack to have a longer Actual Run Time. Remember that the initial time for this test is the Derived Run Time reduced by 5 minutes or 10 minutes as previously described. If the battery's measured voltage indicates that a longer run time might be possible, recharge the pack and increment the timer to what appears might be an appropriate time. Keep in mind that as batteries age from usage, the battery's capacity decreases, which means that, at some point, run time will need to be reduced. To keep things simple, it was decided to use no battery protection or battery management system (BMS). The user is then responsible for both battery protection and management. The Derived Run Time Procedure was developed to act as battery protection and the removable Lithium-ion IMR or INR 10440 batteries help to provide some battery management and balancing by charging each battery individually. The Derived Run Time Procedure, as first suggested, used 3.7V as the loaded cut off voltage for a single 10440 battery.

Further research indicated that 3.5V, as close as possible, to its voltage under load would be a better cut off voltage to use for the Derived Run Time Procedure. In the section of this article titled "How to Determine the actual battery run time with some testing information Part 1", there was some important information about Lithium-ion 3.6/3.7 nominal voltage batteries with a charge termination voltage of 4.2V. In that section it was noted that the capacity, in milliamp hours (mAh), printed on the label is not the actual, usable capacity and an explanation as to why was given. I also explained why only 80% of the capacity is typically recommended to be used from the pack by electrically powered aircraft modelers. Information on the discharge of the Efest IMR 10440 cells was found online. The discharge graph showed that, when this battery is discharged at a constant 0.1 amps (A), 0.2A and 0.5A, the usable capacity is about 0.3 amp hours (Ah) or 300 milliamp hours (mAh). The two tested locomotives' average amp draw, using the 1/2 throttle setting, is in the 0.36 amp (A) to 0.37A range. In my testing, when the loaded cut off voltage of 3.7V was used, the average capacity, in milliamp hours (mAh) returned to the battery, was about 155mAh. That is only about 52% of the 300mAh actual capacity at this amp draw. When a loaded voltage of 3.5V was used as the cut off voltage, an average of about 235mAh was returned to the battery. That is 78% of the 300mAh actual capacity, and right in the 80% desired range. Also remember that the charger's noted returned capacity, in milliamp hours (mAh), is a bit more than the actual capacity (mAh) taken from the battery during the discharge. Note: This information is only left here for reference. Using a Li-Po battery is NOT recommended. Run time numbers for this locomotive were previously noted in the section titled "Actual Battery Run Time" They were noted as;

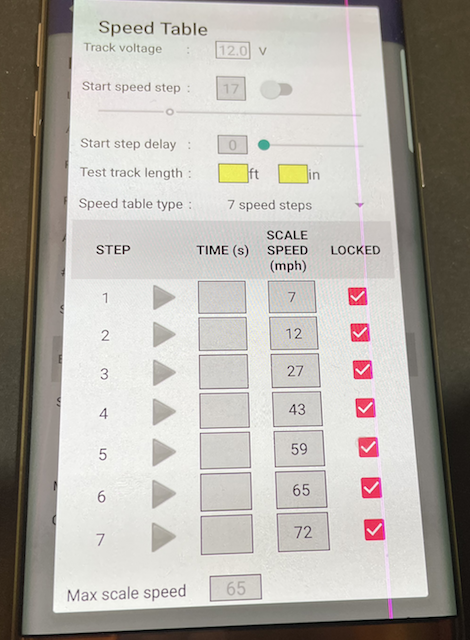

As noted now, the procedure has been changed to use voltage, not the percent of usable capacity left in the pack. When this locomotive and battery combination was originally tested, only 1 Speed Step was used to configure it. The locomotive was reconfigured using 7 Speed Steps.  The new configuration is shown above. I changed the name to 12.0V. It doesn't matter what you call it, as LocoFi™ has no way to verify the voltage. It's just a name I chose to represent a 3S Lithium-ion battery pack. The Step 7 speed is shown as 72 mph, which is above the speed for the full-scale EMD GP15-1, which is 65 mph. The Max Scale Speed was set to 65 mph. I did the Derived Run Time test again on the CSX using a 3.7V under load cut off. The numbers are presented here with voltages this time.

Voltage check after first 10 minute run using a Li-Po Cell Voltage Checker. The derived time remained the same at 40 minutes. A timer was set at 35 minutes, since the demo layout is flat and there is only a boxcar, gondola and caboose available to switch. The train was run in a prototypical manner including picking up cars, running them point to point, dropping them off on sidings, etc. At the end of 35 minutes a battery's voltage read 3.780V. That might be the run time for this Li-Po/Loco combination, or I might try to stretch it to 40 minutes next time. (There was no next time.) This section was added to demonstrate why running at 1/2 throttle, the mid-point, draws more average amps, current, than running at full throttle. It also demonstrates that the calculated maximum amp draw is well within the operating range of the battery and LocoFi™ decoder. Knowing the maximum average amp draw gives a good indication as to whether or not the amp draw exceeds the maximum allowable amp draw, current rating, of a given battery and its speed controller. The LocoFi™ 3 decoder is rated, in the Technical Specifications, to a maximum of 1.5 amps (A) (1A motor). I have no idea what 1A motor means. The Efest IMR 10440 batteries are rated to a maximum of 3 amps (A). The current limiting factor, using those two items, is the speed controller in the decoder, which has a maximum current rating of 1.5 amps (A). Knowing the average amp draw is also useful in predicting how long the battery will provide power before it is depleted to its lowest specified voltage. I have repeatedly stated that the average amp draw for my two Walther's GP15-1s is 300 milliamps (mA) or 0.30 amp (A). I wanted to verify that, but... The following was found in an email from the LocoFi™ team on May 15, 2022. "We can't agree more with the run time determination method. We have however noticed that for some reason notch 4 (or somewhere midway throttle), the current consumption seems to be maximum (more than "full" throttle). If that happens to be the case, the run time may decrease." That note made me wonder. I knew that the electronic speed controls (ESCs), that we use in aircraft models, were less efficient at partial throttle or when using restricted throttle settings to keep the current down. I decided to investigate to see if running the LocoFi™ decoder at about 1/2 throttle significantly increased the maximum average amp draw. The following data indicates that at 1/2 throttle, with the headlight on, has a maximum average current draw of about 360 milliamps (mA) or 0.36 amp (A) to 370 milliamps (mA) or 0.37 amp (A), which is about seven hundredths (0.07) of an amp higher than when using the full throttle, with the headlight on, as the maximum average amp draw. The higher amp draw, of up to 0.37ish amps, has no significant negative effect on the throttle circuit in the decoder or battery as chosen, as both the allowable battery maximum current of 3 amps (A) and the throttle's allowable maximum current of 1.5 amps (A) is more than enough "overhead" to keep them well within their safe operating range. The following data demonstrates that while the Derived Run Time Procedure should really be completed using approximately half throttle, with the light on, to achieve the highest average amp draw, not at full throttle, with the light on, either will work to check the maximum average amp draw to see that the battery choice and throttle amp draw limits are not possibly being over taxed. It should also be noted that this is the maximum average amp draw. The total run time average amp draw, to the maximum allowable time, will be lower. This demonstrates the "worst case scenario". I did some testing to verify that the 300 milliamps (mA) or 0.3 amp (A) draw was correct for both locomotives when using full throttle with the headlight on. I followed that up with testing the maximum average amp draw at half throttle, with the headlight on. Nine Efest IMR 10440 batteries were removed from storage. They were numbered for reference and their resting, stabilized voltages were taken. They were all a bit over the typical 3.8Vish storage charge range.

The ambient basement temperature was 17.5 degrees C to 18.5 degrees C during all of the following testing. That is 63 degrees F to 65.3 degrees F, which is on the low side for using these types of cells efficiently. Batteries 1 - 6 were individually charged at 350mA (-.35A) to 4.2V using a Revolectrix Gt500 charger. Batteries 4, 5 and 6 were charged first. The capacity shown on the charger noted 72% left. Batteries 4 and 5 showed 68mAh returned and battery 6 67mAh returned. The time for each battery's charge was in the 25 to 27 minute range. Batteries 1, 2 and 3 were charged. The batteries presented some varying charge information, when compared to batteries 4, 5 and 6. Batteries 1 and 2 showed 64% of remaining capacity and battery 3 66%. The charge times varied from 25 to 29 minutes and between 76mAh and 80mAh were returned to the three batteries. Note: Batteries 7, 8 and 9 were charged on the EBL chargers, at this time, to be used later to add LocoFi™ to my home network. Both locomotives had already been configured with these batteries, so reconfiguration was not necessary. The test procedure, to find the capacity used to calculate the average amp draw, was to run the locomotive at full throttle with the headlight on on the loop of Walthers track for six minutes, which is 1/10 (0.1) hour. Running the test for the first six minutes provides the maximum average amp draw at the maximum average voltage. After about four hours of rest time, the charged resting, stabilized voltages were; #4 - 4.148V, #5 - 4.149V and #6 - 4.150V. After the six minute motor run, at full throttle with the headlight on, and a rest time to a resting, stabilized voltage, the recharge to 4.2V was completed using a charge current of 35mA to determine the capacity returned by the charger. While the noted input capacity, when being charged, is a bit more than the actual capacity withdrawn during the test, the few added mAh is insignificant. CSX Recharge Test 1

Battery 5: Stabilized, Resting Voltage: 4.054V, Charge Time: 16:46, Charged mAh returned: 32mAh

Battery 6: Stabilized, Resting Voltage: 4.057V, Charge Time: 15:37, mAh returned: 31mAh

For the 2nd test, the already charged batteries resting time was about 17.5 hours. The resting, stabilized voltages were; #1 - 4.140V, #2 - 4.146V and #3 - 4.147V. The ambient temperature was 17.9 degrees C. The discharged resting, stabilized voltages were taken after resting at least 2 hours. CSX Recharge Test 2

Battery 2: Stabilized, Resting Voltage: 4.059V, Charge Time: 15:45, mAh returned: 28mAh

Battery 3: Stabilized, Resting Voltage: 4.060V, Charge Time: 16:02, Charged VmAh returned: 29mAh

This confirmed that the average maximum amp draw was about 300mA or 0.30A For the first Conrail test, after resting for about 13.5 hours, the charged resting, stabilized voltages were; #4 - 4.155V, #5 - 4.155V and #6 - 4.152V. The ambient temperature was 17.9 degrees C. The discharged resting, stabilized voltages were taken after resting at least 2 hours. Conrail Recharge Test 1

Battery 5: Stabilized, Resting Voltage: 4.060V, Charge Time - 15:21, mAh returned: 29Ah

Battery 6: Stabilized, Resting Voltage: 4.059V, Charge Time: 14:39, mAh returned: 29mAh

For the 2nd test, the batteries were rested at least 2 hours. The resting, stabilized voltages were; #1 - 4.157V, #2 - 4.154V and #3 - 4.156V. Conrail Recharge Test 2

Battery 2: Stabilized, Resting Voltage: 4.062V, Charge Time: 15:20, mAh returned: 28mAh

Battery 3: Stabilized, Resting Voltage: 4.064V, Charge Time: 14:37, mAh returned: 28mAh

The maximum average current draw was a bit closer to 290mA (0.29A), but noting 300mA (0.30A) is definitely close enough. Why is there a slight variation in the calculated amp draw? It is most likely due to trying to get the locomotive stopped and shut down at EXACTLY 6 minutes of run time. While it took a few days, the testing did show that the average amp draw, for both of these locomotives, is about 0.3A or 300mA and easily in the safe operating range of the decoder's speed controller. 0.3A for the average amp draw also allows plenty of "headroom" for grades and fairly long trains. The question still remained, "Is this the true maximum average amp draw, or is it too low?" The previous testing, using full throttle with the light on, showed an average amp draw of 29mA to 30mA (milliamps) or 0.29A to 0.30A (amps). For this amp draw test, instead of using full throttle with the light on, the throttle was run on Step 4, mid-throttle for my 7 Step configuration, with the light on for 6 minutes. The batteries were fully charged and after about 2 hours of rest time, the charged stabilized, resting voltages were; #4 - 4.157V, #5 - 4.158V and #6 - 4.157V. CSX Recharge Test

Battery 5: Stabilized, Resting Voltage: 4.038V, Charge Time: 16:17, mAh returned: 36mAh

Battery 6: Stabilized, Resting Voltage: 4.038VV, Charge Time: 16:12, Charged Volts mAh returned: 36mAh

This is a definitely higher average current draw, as the LocoFi™ team indicated that it might be. For the second average amp draw test, after about 2.5 hours of rest time, the charged resting, stabilized voltages were; #1 - 4.158V, #2 - 4.155V and #3 - 4.57V. Conrail Recharge Test

Battery 2: Stabilized, Resting Voltage: 4.034V, Charge Time: 16:44, mAh returned: 36mAh

Battery 3: Stabilized, Resting Voltage:4.036V, Charge Time: 18:18, mAh returned: 38mAh

For the CSX Derived Run Time Procedure Test 1, the batteries had been rested for 16.5 hours and their stabilized resting voltages were; Battery #4 - 4.135V, Battery #5 - 4.141V and Battery #6 - 4.121V. Derived Run Time Test 1

The maximum average amp draw for this locomotive with this resultant battery, which had been previously determined, is 357 milliamps (mA) or 0.357 amp (A). After resting for 3.5 hours from the Derived Run Time Procedure Test 1, Battery #6's stabilized, resting voltage was 3.608V. The charger noted 8% of the battery's capacity left in the battery. The battery was charged at 350 milliamps (mA) or 0.35 amp (A) to 4.2V. It took 59 minutes and 1 second to return 238 milliamp hours (mAh) or 0.238 amp hours (Ah) to the battery. The Math to Verify:

For the CSX Derived Run Time Procedure Test 2, the batteries had been rested for 17.5 hours and their stabilized resting voltages were; Battery #1 - 4.121V, Battery #2 - 4.143V and Battery #3 - 4.139V. Derived Run Time Test 2

After resting for 3 hours from the Derived Run Time Procedure Test 2, Battery #1's stabilized, resting voltage was 3.610V . The charger noted 8% of the battery's capacity left in the battery. The battery was charged at 350 milliamps (mA) or 0.35 amp (A) to 4.2V. It took 55 minutes and 25 seconds to return 230 milliamp hours (mAh) or 0.238 amp hours (Ah) to the battery. The Math to Verify:

The math works out well and is totally in line with the Derived Run Time Procedure Test 1. Storage Voltage Note: Once an operating session is totally completed for a resultant battery, let the individual batteries rest for at least an hour. Measure the stabilized, resting voltage of each individual battery. If the resting voltage is between 3.7V and 3.85V, put that battery away. If the battery is less than 3.7V volts, charge that battery on the EBL charger for about 20 minutes. Immediately read the voltage once the battery is removed from the charger. If the voltage is between 7V and 8V, put that battery away. Repeat for 10 minutes only if the resting voltage is significantly under 3.7V. A Note About This Actual Run Time Test After "sleeping on it", I decided not to do another Actual Run Time Test. The new data, using a cut off voltage of 3.5V, made it clear that 35 minutes to 40 minutes of run time could be quite possible. The following is the original Actual Run Time Test when 3.7V was used as the cut off volts. An Actual Run Time Test was completed using a prototypical run on the Demo layout. The prototypical run consisted of runs on the loop, figure 8 and through the reversing loops at various speeds. It also included making up trains, picking up and delivering rolling stock to various points. The batteries were recharged. A prototypical run test was performed on the demo layout for a timed 35 minutes, as that is what the similarly powered Conrail proved capable of doing during its second prototypical demo layout run. After 30 minutes of prototypical run time, a battery measured 3.675V. An hour later, that battery measured 3.705V. I also measured the other two batteries an hour after they had been used. One was at 3.716V and the other was at 3.712V. Both locomotives can be run prototypically on the flat demo layout for 30 minutes each. To view both 3S 10440 conversions running together, view this part of the Part 6 video on YouTube. Using 3.5V under load, instead of the 3.7V under load, as this test did, I would expect about a 40 minutes safe Prototypical Run Time. While the locomotives are the same type and from the same manufacturer, there is no way to really know if they are the same or not. The body shells were molded differently, so obviously they were from different runs. The gears could be "tighter" in one loco compared to the other. The 3S Li-Po, inside the body shell of the CSX, only has short leads to the decoder in the CSX. The Conrail has long leads of tiny AWG wire from the gondola going into the decoder that is in the locomotive. The AAA battery boxes, which are not designed for this purpose, are less efficient than directly connecting batteries together to make a resultant battery. The good news is that by reducing the number of batteries from 4 to 3, in the resultant battery in the gondola attached to the Conrail, was that there was a 50% increase in the Derived Run Time Procedure. A gain was expected, so it was worth the change, as the Conrail runs at a scale 65 mph while drawing less amps for a longer time. The reason that the 4S 10440 resultant battery was tried first was that it was simple to wire up the two AAA battery boxes and the combined voltage, of the four batteries in series, was within the LocoFi™ voltage specifications. Modifying the boxes to provide three batteries in series wasn't that much harder. The main problem was that I'd not remembered a very basic principle; if nothing changes in what is causing the load and more voltage is applied, the amps jump way up. I should have realized that a 3S pack would have sufficed, based on the first conversion of the CSX to a 3S Li-Po. On May 27, 2022 I confirmed that the "real or actual" usable capacity of the IMR Lithium-ion 350mAh 10440 batteries was a lot less than the stated capacity! That was disappointing. I worked for the better part of that day to try and understand what was going on. I also spent the majority of the following day testing the capacity for the 3S 300mAh Li-Po used in the original Walthers' EMD GP15-1 CSX conversion and a 2S 800mAh Li-Po, which was the lowest capacity battery I have for my planes. I found a Website that reviewed the actual 10440 batteries that I'm using, the Efest IMR10440 V1 350mAh (Black). The results of the testing, presented on that Webpage, contains a lot of graphs. The graphs are created using a constant load connected to the battery with the voltage noted over time. The results and information garnered from a constant load apply nicely to predicting how long a device like a laptop or smart phone can "run" before requiring a recharge. The linked video, EEVblog #140 - Battery Capacity Tutorial, explains this well. Unfortunately, that type of testing, and the results it yields, does not directly apply when using an electric motor that can be varied in speed of rotation. The amp draw (the load) varies over time as the motor speed (voltage) is varied. When the locomotive is not moving, only the very low draw of the LocoFi™ system is drawing current from the battery. As the locomotive begins to move, that is the electric motor is engaged, the current jumps up to get the motor, connected to its load, rotating. The load on the motor includes the motor itself, the drive components, including the specific gearing, axle friction, the friction of all of the wheels on the track and the load of the number of cars in the "train" along with their weight and wheel axle and track friction. This spike in load can be extremely short, but it is there. It could last longer if the "train" has a lot of rolling stock or is starting on an "upgrade". All of the electronic speed controls (ESCs), that I am familiar with, that are used for electrically powered model airplanes, are most efficient at full throttle and less efficient in mid-range. Therefore, more energy is "wasted" as heat in mid-range. That is why I made a big mistake when I first converted the Walthers EMD GP15-1 Conrail to use a trailing battery car using a 4S IMR 10440 resultant battery. I recently received an email from the LocoFi™ Team with the following statements in it. "We can't agree more with the run time determination method. We have however noticed that for some reason notch 4 (or somewhere midway throttle), the current consumption seems to be maximum (more than "full" throttle). If that happens to be the case, the run time may decrease." The information about "notch 4" has some direct implications on determining the derived run time and needs to be investigated further. A Revolectrix GT500 was used to discharge and charge each individual battery in a 3S 11.1V 300mAh and a 2S 7.4V 800mAh Li-Po. A Fluke multimeter was used to read the individual battery voltages during the stabilization stage. Each of the 5 batteries was individually discharged from their storage voltage to 3.67V using a 1C discharge rate. 3.67V was chosen to allow the battery to "bounce back" to a stabilized, resting voltage of approximately 3.7V for the charge test to see how many mAh was returned to the pack when it was fully charged. Note: I later learned that, for several reasons, the discharge should have been terminated at 3.5V loaded not 3.67V loaded. Each of the 5 nominal 3.7V batteries with a 4.2V charge termination voltage took about 3 hours to stabilize right around 3.7V, as expected. After the batteries reached their stabilized state, each battery was individually charged to termination using the GT500 charger. Noting the mAh returned to the battery on the charger's display, instead of what was discharged, provides a slightly higher mAh to be displayed, but, through actual testing, I found it to be almost inconsequential. The previously tested IMR Lithium-ion 350mAh 10440 batteries, that had been tested in the same manner, returned a disappointing average of 156mAh or 45% of the stated capacity. The 300mAh Li-Po batteries returned an average of 223mAh, which explains why their derived time was 40 minutes compared to the 350mAh 10440 batteries that only had a derived time of 30 minutes. An average of 700mAh was returned to the stated 800mAh Li-Po batteries. It is important to remember that all of these charges had been started at the same, 3.7V, stabilized resting voltage. As I've previously stated, stabilized resting voltage is not an accurate way to predict the remaining capacity. The GT500 charger does use that method to display a percent of capacity. Obviously it is not that accurate, but... At 3.7V stabilized and resting, the charger noted 13% capacity remaining when the IMR batteries were started, 12% for the 300mAh Li-Pos and 11% for the 800mAh Li-Po. What that really demonstrates is that there is not very much useful capacity remaining once the batteries reach a stabilized resting 3.7V. While the 10440 total batteries capacity average was very, very disappointing, it is still quite usable for 30 minutes of prototypical running. |