|

Updated: August 2025 At first, I was very satisfied with the approximately 60 minutes of prototypical run* time, for each of the two diesel Walthers' Trainline EMD GP15-1 locomotives and the IHC 2-8-0 Consolidation steam engine, when using the 10440 (AAA) size Lithium-ion batteries that I'd chosen to use.

Early in my Dead Rail exploration, I used 4 Soshine 10440 size 3.2V 280mAh Lithium Iron Phosphate (LiFe, IFR, LFP) in trailing battery cars and 3 of the Soshine batteries in the tender of the lower maximum speed steam engine. I also used packs of 3 Efest Lithium Manganese Oxide (LMO, IMR) 10440 size 3.7V 350mAh batteries and 3 Vapcell Lithium Nickel Manganese Cobalt oxide (NMC, INR) 10440 size 3.7V 320mAh batteries in all three locomotives. Using the noted Lithium-ion 10440 size cylindrical batteries, I achieved a prototypical run time of one hour. Please see my article titled, "Battery Availability" for my current battery availability information. There is a YouTube video, that notes that the suppliers of Dead Rail systems wanted to achieve a two hour prototypical run time. It appears that that run time was based on clubs having two to three hour operating sessions. I don't know anything about model railroad club operating sessions, but I cannot believe that any single locomotive, or locomotive consist, would be run for the full operating session time. Based on my experience at the RC flying field, there is a lot more talking than flying. During a discussion that I'd had with a flying buddy, who also does HO model railroading, I mentioned that I was able to do prototypical runs for a half an hour using the IMR Lithium-ion 3S 11.1V 350mAh battery pack. He noted that he thought that was plenty of time. (I had not tested the batteries to their full potential at that time.) On June 5, 2022, I did a YouTube Search for Model Railroad Operating Session. I selected Filters and chose Upload Date. I scrolled down the page until it reached the bottom of the searches and said "No More Results". I started scrolling up from the bottom while noting the video run times and watching a few of the videos that were actually about operating and operations. I did not look at ALL of them! What was obvious was that no single, track powered locomotive ran for two hours in any of the videos. I even searched the results for "live", and, again, no single locomotive appeared to be running for two hours. I did not find any whole operating sessions that were videoed from beginning to end with no edits. On July 14, 2022, Jimmy at the YouTube channel DIY and Digital Railroad posted a video titled Cramming a lot of model train fun into a short amount of time. He shared three different ways that he does operating sessions with a single locomotive based on the time it takes to complete the switching tasks that were randomly chosen. His longest session was expected to take 30 minutes to complete. He states, "This is the long one and it's probably going to take you about a half hour to complete." Further Google research using "Model Railroad operations", as the search term, provided a bit more insight. An article titled, "How to Play With Trains", by Lance Mindheim, provided some guidance. He notes, "I'm talking about frequent sessions that are easy to set up and can be run on a moment's notice, 15 to 45 minutes at a time, ...". The topic "How long do you run your trains?" on the Classic Toy Trains forum also gives some clues as to run time in various posts. arkady: "Mostly I run an individual train for only about half an hour or so at a time."

A YouTube Video of single loco operations

A YouTube Video of two locomotive consist operations

02/12/23: With a lot more prototypical run time on "My First HO Train Layout in a Long, Long Time", my locomotives were safely achieving an hour of prototypical run time with either 3 IMR 10440 size 350mAh or 4 IFR 10440 size 280mAh batteries. I found that I was ready for a break after that hour. If I wanted to go longer, another set of charged batteries could be swapped in and the session continued. Next I tried 3 Efest IMR 14500 (AA) size 3.7V 650mAh batteries in series, Using these, I was able to achieve over two hours of prototypical run time. Even though I found myself mostly doing 1/2 hour prototypical runs, I wanted to be able to use Lithium Iron Phosphate batteries, as they are the safest type of Lithium-ion battery for Dead Rail use without a PCM or BMS. When the Soshine 3.2V 280mAh 10440 (AAA) size LiFe batteries became hard to obtain, I was forced into investigating the use of 4 LiFe 14500 (AA) size batteries. Later I learned that I could achieve a 2 hour prototypical run time using 4 14500 (AA size) 600 mAh LiFe batteries, LocoFiTM and the Walthers' EMD GP15-1s. My article, "Selecting the Battery for the Trailing Battery Car" explains how I was able to achieve the goal of using 14500 size LiFe batteries. I recently completed prototypical run time tests using 4 14500 (AA size) 600 mAh LiFe batteries, a Soundtraxx Blunami decoder, and an Athearn RS-3 Ready to Run with DCC and Sound and found the prototypical run time to be at least 4 and 1/2 hours. Because I can only get 3 10440 (AAA size) batteries in the tender of my 2-8-0 locomotive, its run time is still one hour. Only the user can determine the prototypical safe run time, without draining the battery too low. Almost every conversion to Dead Rail, battery on board, is unique to the locomotive and the actual track plan of the layout. There are several factors and variables that make a specific, across the board answer, extremely difficult. Tools Required

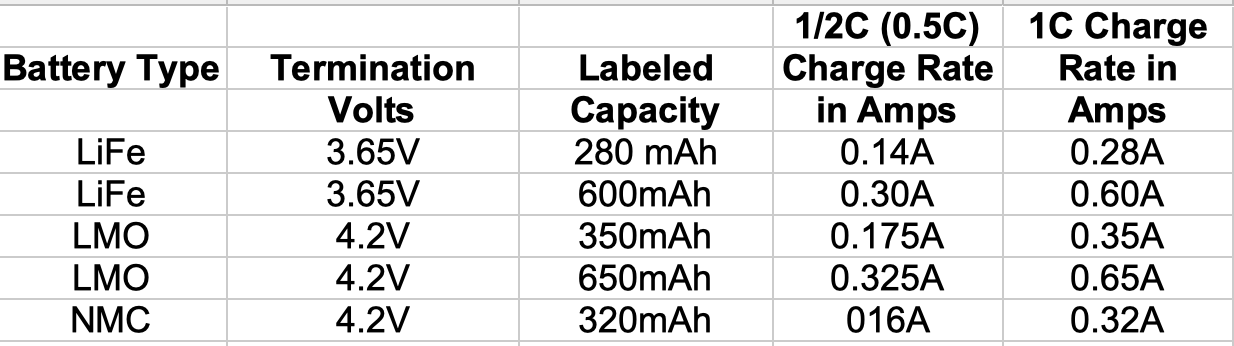

The Procedure Set up the preconfigured locomotive, battery car with all but one battery inserted, and the rest of the train on the actual layout for a prototypical run to include all kinds of running at various speeds as well as some shunting of rolling stock. Include all of the rolling stock for a prototypical running session, both behind the locomotive/battery car combination and at points to be switched, moved, etc. The battery car must have its battery box accessible for this procedure. Insert the remaining battery. Launch the LocoFi™ App or Soundtraxx Blunami App, as applicable, and connect to the locomotive to the App. Do a prototypical run for thirty (30) minutes (1/2 hour or 0.5 hours). I have done it with 15 minutes (1/4 hour or 0.25 hours), but half an hour yields a more realistic value. Remove all of the batteries and set them aside. If measured with a voltmeter, shortly after the load (running the train) is removed, the voltage can be noted rising over time. I call this the "voltage bounce back period". For Lithium based batteries, it can take several hours to reach their maximum resting voltage. It is not necessary to wait that long, but it is a good practice to wait for maybe 30 minutes before recharging. After waiting a bit, place all of the batteries in a true Multi-Chemistry Smart Charger. Fully charge the batteries, to their recommended termination voltage, at as close to a 1/2C (0.5C) charge rate as possible with the Multi-Chemistry charger being used. (Charging at 1C is also acceptable, at times, when a quicker charge is desired.) The charge rate is the value of the current flow, in amps, that the charger is set at to charge a particular battery. That setting varies by the battery's capacity in milliamp hours (mAh). Charging with too many amps, a high rate, can damage a battery. If charged with too low of a rate, lower amps, it just takes longer, but that is fine! The following table shows the termination voltage and the number of amps to charge safely at, for the cylindrical Lithium-ion batteries discussed in this article. Hopefully you can see how the charging amps were determined.

Oops, missed the decimal; 016A should be 0.16A The values for the charge current may need to be rounded depending on the multi-chemistry charger's input value number of decimal places. When the charge has been completed, note the battery with the highest mAh returned on the charger's screen. That is the battery's mAh to use when calculating the initial maximum prototypical run time based on the battery's usable capacity. Because of the way a Lithium-ion charger works, the noted mAh returned, when the charger terminates, is always higher than the actual mAh removed from the battery. A really good explanation of how a Lithium-ion battery charger works is explained in a video titled EEVblog #176 - Lithium Ion/Polymer Battery Charging Tutorial. I use 80% of the stated capacity as the cutoff point for the maximum discharge used to calculate the prototypical run time. Why only 80% is explained here. For the batteries discussed here, the maximum acceptable returned mAh should be no greater than;

The Procedure: 1. Fully charge the battery and then do a 30 minute (1/2 hour) prototypical run, as previously mentioned. 2. Let the batteries rest for about 1/2 hour before recharging them. 3. Recharge the battery and note the highest mAh returned to a single battery. Calculate YOUR average amp draw YOUR average amp draw will differ from the following example. Please adjust the values in the following formulas to YOUR real values. Do not use the ones in the example. Keep the time as close to 30 minutes (1/2 hour or 0.5 hours) as possible, as it keeps the math simple. Finding the Average Amp Draw - the Example IMPORTANT!: Amps Hours (Ah) equals Milliamp Hours (mAh) divided by 1000; ie. 480mAh divided by 1000 equals 0.48Ah (amp hours). The average amp draw equals the highest milliamp hours (mAh) returned by the charger to a single battery and then converted to amp hours (Ah) and then the Ah divided by the time in hours. i.e. 125mAh returned divided by 1000 equals 0.125Ah returned.

Divide the maximum allowable mAh to be drained from the battery, which is 80% of the labeled capacity, by the average amp draw. The resultant value is in hours. To change hours to minutes, multiply the hours value by 60. Using the example's average amp draw of 0.25A (Remember YOUR average amp draw value will be different.), the following would be the maximum time to try for the various capacity batteries.

The maximum "returned by the charger" values, are not to exceed the ones noted above, that provide the initial maximum prototypical run times. A "real" prototypical run is necessary to confirm the estimation provided by the above data. The following is an example, using real values, for my locomotive and layout. This is ONLY an EXAMPLE. YOUR values Will be different! The batteries used were the Vapcell NMC/INR 10440 size labeled 320mAh. 80% of 320mAh is 256mAh with a suggested maximum initial prototypical run time of approximately 62 minutes, as noted in the previous data. 62 minutes is 1.0333333 hours. The returned mAh, as noted by the charger was; #1 236mAh, #2 241mAh and #3 240mAh. After the 62 minute prototypical run, the charger returned highest mAh noted was 241mAh. That was less than the initial maximum predetermined mAh of 256mAh. That verified that these batteries, in this locomotive and on my layout have a safe 1 hour prototypical run time. That was the information I was looking for. If the returned mAh exceeded 256mAh, in this case, I would have to cut back the prototypical run time and try another prototypical run to see how many minutes would be safe and within the maximum limit. Recalculating My average amp draw (just for fun, since it turned out to be okay on the first try, and to get another data point)

This confirmed that, with this specific loco, on my layout and at the ambient temperature of my basement, one hour is the typical prototypical run time.

|