Once again, my impatience and lack of knowledge and research sent me down a rabbit hole that I really did not need to go down. The next size larger Lithium-ion cylindrical battery is the 14500, which is approximately 14mm in diameter and 50mm long. That is about the same as a 1.5V AA "dry cell", which is approximately 14.5mm in diameter and 48mm long. Unfortunately, AA battery boxes, with two batteries side by side or four batteries in a "square" shape, are too wide to fit into HO scale rolling stock with the battery boxes laying flat on the floor of the frame. That is why I'd initially ruled them out. With a bit of Internet searching an AA 3S battery box was found. Its given length was 6.3", which would fit in both the gondola and boxcar. Unfortunately, the day after I ordered them, 05/31/22, they disappeared from their Website! I found an alternate source. The 3S AA battery boxes arrived on 06/06/2022. I also ordered 6 Efest IMR14500 V2 650mAh High Discharge Button Top batteries. The six 14500 batteries arrived on June 2, 2022. I was surprised at how quickly the batteries arrived. My first impression was that they were HUGE when compared to the 10440 batteries. I had misread the description and they are button top, not flat top, but that is fine. Each battery's resting voltage was measured upon arrival. They fell between 3.879V and 3.902V, which is in the normal range when compared to other Lithium based batteries that I've received. I found a Web review of these batteries here.

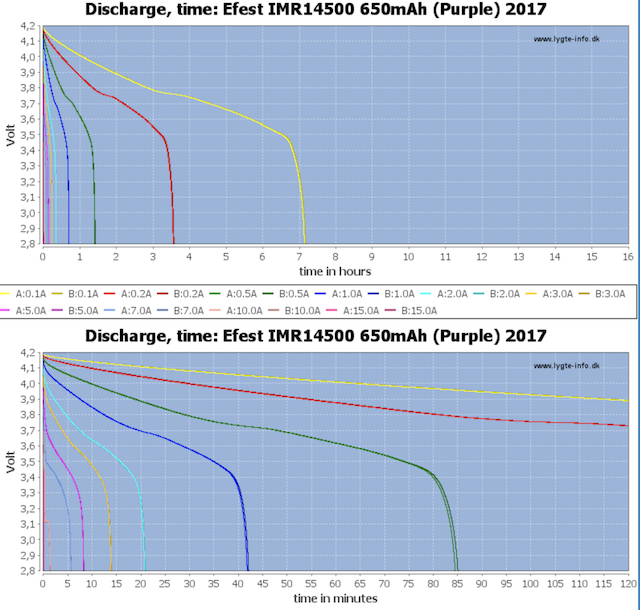

Two graphs from that site. I expected the amp draw average to go up because of less resistance in the batteries, thus increasing the step 7 speed in the Apps config section. Even if it does, it looks like these batteries could provide a significantly increased prototypical run time. We'll see. The time consuming process of charging each single battery to 4.2V at 0.65A (1C) and then discharging at 0.65A (1C) to 3.7V began. Since these were the first cycles on these batteries, the capacity noted was expected to be lower than when they'd been cycled a few times. Data was gathered using a Revolectrix GT500 charger and Fluke multimeter. All testing was done in my basement, which was at 17 degrees C or about 63 degrees F. The somewhat low temperature caused the measured capacity to be a bit lower than if they had been tested in the "normal" room temperature range of 20 degrees to 22 degrees C. Unfortunately, the whole day of testing did not go well and I had to throw out my results! I learned that by setting the discharge termination to 3.7V, the Revolectrix charger did not maintain the set current, 0.65A, for the complete discharge. It tapered the current lower as the voltage approached 3.7V, which allowed a longer discharge time that affected the discharged mAh value. In the meantime, I'd also been doing more research into using 3.5V as the the cutoff voltage. Since I'd already calculated the average amp draw of the locomotive as 0.30A, I should have been discharging at that value instead of the 1C value of 0.65A. The 0.30A amp draw value was for running the locomotive at full throttle, with the headlight on, NOT using the mid-throttle setting, with the headlight on, which I'd not tested yet. All of the battery capacity testing was done in my basement in southeastern Michigan. The basement stays at about 17 degrees C (~63 degrees F) the year round. The layout is in the basement, so the testing was done there as well. 17 degrees C is at the low temperature end of the range for the usage of Lithium based batteries. That means that at the more usual "room temperature" of about 23 degrees C (~73 degree F) the capacity will be somewhat greater. From its storage voltage, a single Efest IMR 14500 650mAh battery was charged to 4.2V using a Revolectrix GT500 battery charger. The battery was rested for 3 hours and 16 minutes, as I had other things to do before starting the discharge. The Fluke MM read the stabilized resting voltage as 4.149V and the GT500 as 4.15V as the discharge began. The GT500 was set to discharge at 0.30A, as this is the estimated amp draw for each of the two locomotives that I have, down to 3.2V. 3.2V was chosen because I didn't want the discharge to stop at 3.5V, the low voltage for the capacity power range check that I've decided to use. I had to manually stop the discharge at 3.50V. GT500 Discharge Data to 3.50V

The math to verify discharge at 0.30A: 1.6758333 hours * 0.30A = 502.75mAh After resting two hours, the stabilized resting voltage read 3.590V on the Fluke MM and 3.58V at the beginning of the charge on the GT500. The battery was charged at 0.30A to 4.2V. 0.30A was chosen because that was the discharge rate and I wanted to compare the discharge mAh (500mAh) to the returned mAh. 533mAh was returned in 2 hours and 9 minutes. 533mAh = 31.98 amp minutes / 129 minutes = 0.247907 average amps

0.30A is technically 0.46C, so not quite 0.5C, which is not an uncommon recommended charge rate for these types of batteries. While testing the previous batteries; Li-Pos and the IMR 10440 batteries, they were recharged after the discharge at a 1C rate, which shortened the time in the constant voltage (cv) stage, and the discharged difference was that the discharged mAh was about 97% of the recharged rate after discharge, not about 94% as indicated here (500/533 = 0.9380863). I probably should have recharged at 1C. While I'm still not planning to change to these batteries from Efest IMR 10440 350mAh 3S battery at this time, this does demonstrate that a prototypical run time of one hour and forty minutes would be possible on the flat demo layout with the rolling stock consist being only a few cars. While gathering the batteries and 3S AA battery boxes and considering whether the 14500s were a viable option, or even necessary, there was a discussion going on in the LocoFi™ forum about consisting locomotives with a trailing battery car. That discussion is located in the thread titled "A 6th Video featuring LocoFi is now on YouTube". It appears that, when using a 3S 14500 resultant battery in a trailing car, the almost AA size, could supply the power long enough for consisting two locomotives for 1/2 hour, as described in the thread. Consisting DOES require small connectors, like the MicroMark Micro Connectors, to be used between the battery car and locomotive as well as between locomotives to be used in the consist. That is quite an advanced skill to get that all together. Again, at this time, the beginning of August, 2022, I have no desire to swap out the 10440 setups with the 14500s. I have what I need to do the swap, and it is physically feasible, I just don't see the point in doing it. If I do want to do prototypical running for more than half an hour, swapping out the 3 10440 batteries is super easy. I'm storing the new 14500s and battery boxes, at least for now. |