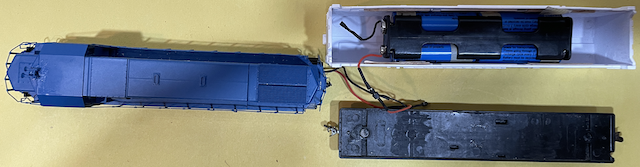

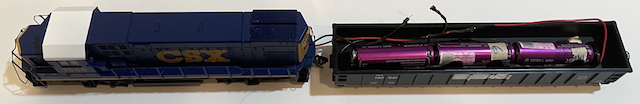

Updated the end of August 2025 The Products I Am Currently Using for Dead Rail/Battery on Board Locomotives The Locomotives: Walthers' EMD GP15-1 - Standard DC - CSX from a Walthers' Flyer Express Fast-Freight Train Set, a Walthers' EMD GP15-1 - Standard DC -- Conrail, Athearn HO RTR RS-3 w/DCC & Sound, CPR #8451 and an old stock, new, in the box, IHC 2-8-0 Consolidation purchased from an Ebay seller. DULLHB - LocoFi™ 3 WiFi Sound Decoder for HO Locomotives: installed in the GP15-1s and 2-8-0 Consolidation. An old Samsung Galaxy S7 Edge, found in a drawer in my house, is used to run the FREE LocoFi™ App. Soundtraxx Blunami BLU-21PNEM8 installed in the Athearn ALCO RS-3 RTR. The old Samsung Galaxy S7 Edge and a small, older iPhone are used to run it. Rolling Stock for Battery Cars: A Walthers' Trainline 53' Smooth-side gondola, Norfolk Southern with a DIY cover made from a boxcar roof picked up at a train show & two Trainline 50' Plug-Door Boxcars; Soo Line & Canadian Pacific with the boxcar shell made easily removable.

It is important to note that 10440 size cylindrical Lithium-ion batteries are about the size as AAA alkaline batteries and that 14500 size Lithium-ion cylindrical batteries are about the same size as AA alkaline batteries. Originally used Battery Boxes:

3 x 1.5V AAA Series Connection

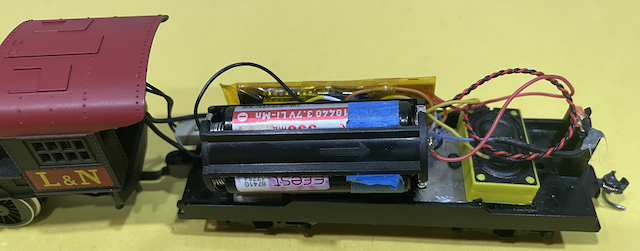

An AA 3 in-line battery box for 3 14500 size Lithium-ion batteries. DGZZI 4 x AA Battery Holder

The AAA size battery boxes were used with some very specific Lithium-ion 10440 (AAA) size cylindrical batteries. Only the 3 x 1.5V AAA Series Connection battery box, is in use at this time. It is in the tender of the Consolidation steam locomotive and holds 3 Lithium Nickel Manganese Cobalt Oxide, LiNiMnCoO2 (NMC, INR) 10440 Vapcell INR10440 320mAh 3A High Discharge Button Top batteries. The first two digits of a 10440 cylindrical Lithium-ion battery notes the approximate diameter in millimeters (~10mm). The next two digits note the length in millimeters (~44mm). The zero digit after 44 indicates that it is a cylindrical battery. A 14500 denotes a size of about 14mm in diameter, about 50mm long and that it is a cylindrical form factor. The DGZZI 4 x AA Battery Holder is used with 14500 (AA) size cylindrical Lithium-ion batteries, again with some very specific Lithium-ion cathode chemistries. Connectors: Originally, 32-pin Micro Connector Set from Micro-Mark were used.

I no longer use connectors on the power wires from the locomotives to the battery boxes. In three years, I've never had a desire to switch the battery cars between locomotives.

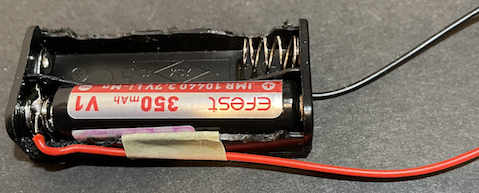

After the successful failure of trying to fit a Lithium-ion pouch 3S battery and the LocoFiTM decoder with its attached speaker into the EMD GP15-1 conversion, I moved on to using 3 Lithium Manganese Oxide, LiMn2O4 (LMO, IMR) 10440 (AAA size) Efest IMR10440 V1 350mAh High Discharge Flat Top batteries in a trailing battery car. The Lithium Manganese Oxide batteries were chosen because of their relative safety. Only 3 of the 10440 LMO batteries, in series, were required to provide the voltage for HO. At first I modified two AAA battery holders so that the three batteries were wired in series and the fourth slot was left empty. I then learned about fake or "dummy" batteries, so that modifying the AAA battery holders was not necessary and the two AAA battery boxes only needed to be wired in series with the fake battery in the fourth slot.

These are available in AAA and AA size. Copy and paste the following to the Amazon Search box to find the item. 2 Pcs AAA Dummy Fake Battery Setup Shell 3a Size Battery Placeholder Cylinder 10440 (AA) size LMO/IMR batteries are no longer available. They had been chosen because LiMn2O4 (LMO, IMR) batteries are the second safest type of cylindrical Lithium-ion chemistry. Soshine 10440 (AAA size) LiFePO4 Rechargeable Batteries Lithium Iron Phosphate batteries (LiFe, IFR), were also used in the two AAA battery boxes, wired in series, and they fill all four slots. 4 of this type of battery were required to provide the voltage for HO for the diesels, but because the 2-8-0 Consolidation has a lower maximum speed, 45 mph, 3 of these are/were used in a different style battery box for 3 AAA batteries. The LiFe batteries were chosen as they are the safest of all Lithium-ion chemistry batteries. These 10440 size batteries are no longer available. I also use 3 Lithium Nickel Manganese Cobalt Oxide, LiNiMnCoO2 (NMC, INR) 10440 Vapcell INR10440 320mAh 3A High Discharge Button Top batteries in the battery box in the Consolidation's tender. Only 3 batteries in series, of this type of battery, are required to provide the voltage for HO. NMC are the 3rd safest type of cylindrical Lithium-ion chemistry. With the disappearance of 10440 LMO and LiFe batteries, I decided to look into fitting 14500 (AA size) into the trailing battery car. 3 Lithium Manganese Oxide, LiMn2O4 (LMO, IMR) 14500 Efest IMR14500 V2 650mAh High Discharge Button Top AA size batteries are used in series to provide the voltage for HO. They were chosen because they are the 2nd safest cylindrical Lithium-ion chemistry. They were originally used in a 3 slot, inline, battery box, but I later changed that to a four slot battery box and used a fake or "dummy" AA battery to fill the fourth slot. When using these batteries in a 4 x 1.5V battery box, a fake AA battery connector is used in the fourth slot. Wanting to use the safest Lithium-ion battery chemistry, Lithium Iron Phosphate, LiFePO4 (LiFe, IFR), I found some Henreepow 3.2v AA 600mAh Rechargeable Batteries. They are 14500 (AA) size. 4 are required to provide the voltage for HO for the diesels. These batteries are used used in all of the battery cars for the diesels. LiFe Batteries for the DGZZI 4 x AA Battery Holder

Update June 6, 2025 It has happened again! The source for a specific battery, that I am using, is no longer available. This is very frustrating. There are other brands of 14500 size, equivalent to AA size, LiFePO4 cells available, but I've only used the HenreePow brand and know that they work and that their stated capacity is reasonably accurate. On June 6, 2025, there were 2 cell and 6 cell combinations of HenreePow cells available on Amazon. HenreePow 2 cells

HenreePow 6 cells

Amazon does have other brands of these 14500 size LiFePO4 cells, but I have no first hand knowledge of them. Be careful when ordering. There is a 14430 size, with a stated capacity of 500mAh, which is not equivalent to AA size and they may not work in AA size battery boxes, but I do not know that for sure. About Lithium-ion Batteries There is a large amount of information presented here. Please don't ignore it, as it gives you the background knowlege that most people don't have about Lithium-ion batteries and using them safely. Using a 3S 11.1V 300mAh Lithium Polymer (Li-Po) pouch Battery, as demonstrated in my first Dead Rail conversion, is NOT Recommended. It was very difficult to cram a decent capacity battery into the HO scale locomotive along with the LocoFi™ module and speaker and required the locomotive's body shell to be removed to charge the battery. It is just not a safe practice to use RC type, unprotected, Li-Po batteries in this application. The 3S (three cells wired in series) Lithium Polymer (Li-Po) battery consisted of three individual Lithium Polymer pouch batteries with a nominal1 voltage of 3.7 volts (V), with a fully charged termination voltage of 4.2 volts (V), and a label stated capacity2 of 300 milliamp hours (mAh).

In this instance, theoretically, if the battery is fully charged and a constant load producing 300 milliamps (mA) of current is applied, the battery will be totally discharged to its minimum acceptable voltage in one hour. Therefore, 300mA for one hour is written as 300mAh (300 milliamp hours, which is 300mA - the current draw - per, or for, one hour) and noted as the battery's capacity. If the load producing the current flow is larger than 300mA, the time will be shorter and if the load producing the current is less than 300mA the time will be longer. The individual Lithium Polymer pouch batteries were wired in series (S), by the assembler of the pack, negative to positive while leaving a single negative and single positive end on the larger resultant battery pack. A series (S) connection is used to increase the voltage of the resultant battery pack. With each individual pouch battery having a nominal voltage of 3.7 volts (V), the three batteries in series, provide the resultant battery pack with a nominal voltage of 3.7V times 3 or 11.1V. The capacity does not change. The resultant battery pack is then noted as a 3S 11.1V 300mAh Li-Po battery. This particular battery was chosen because its advertised physical dimensions indicated that it would probably fit inside the locomotive. Li-Po batteries are not considered a unique battery chemistry as they are based on their related chemistry in other Lithium-ion based batteries. In this case, that would be Lithium Cobalt Oxide (LiCoO2) - LCO with some possible tweaks to the chemistry. "The most common type of lipo battery cathode is made of lithium cobalt oxide (LiCoO2)." Lithium Cobalt Oxide (LiCoO2) - LCO 10440 size batteries are also available in cylindrical batteries and sometimes designated as ICR. (Lithium-Ion Cobalt Round) These types of batteries should also not be used. Using Lithium Cobalt Oxide (LiCoO2) cylindrical batteries, for this purpose, with no battery management system (BMS) or protection circuit module (PCM), is NOT recommended. Sometimes measuring the open circuit resting voltage of a Lithium-ion based rechargeable battery, that has a nominal voltage noted as 3.6V or 3.7V and a charge termination voltage of 4.2V, is used to determine its state of charge (SOC). This method of determining the SOC is not accurate, but it is a very common practice. Measuring resting voltage, as a means to determine the approximate SOC, CANNOT be used with the other two types of Lithium-ion rechargeable batteries, LiFe and LTO! The way that the batteries are being used in this Dead Rail application is not with a constant current load or a constant power load. The power, and thus the current draw, is varied during the useful "life" of the battery capacity. That is much more like the way a radio controlled, electrically powered, vehicle's power is varied. For RC vehicle battery power, it has typically been recommended, as a rule of thumb, that the battery should not be drained to more than 80% of its stated label capacity, which is theoretically 20% left in the pack. Manufacturers and Suppliers of Lithium-ion batteries usually note a minimum discharge voltage. If the battery goes below that voltage, there is a chemical change inside the battery. That change can lead to a possible short circuit inside the battery. The next time the battery is charged, there is the possibility of an uncontrolled thermal event caused by the short circuit inside the battery. A battery's stated milliamp hour (mAh) capacity rating is not really the true capacity that can actually be taken from the pack in applications that allow for the current to be varied or pulsed. Higher currents reduce the usable capacity. The capacity rating, used by some manufactures is based on an industry standard test. For other manufacturers, and especially suppliers who rewrap batteries to sell as "their own brand", the capacity number (mAh) is just made up by the marketing department to insinuate that the battery has more capacity than it actually does. There are HUGE variations in the quality of available batteries for our purposes. In my conversions of the Walthers' GP15-1s, I originally used, and can still use, Soshine 10440 (AAA size) LiFePO4 Batteries. Because the battery cars can hold a battery pack containing four 14500 (AA size) LiFe batteries, I now use them exclusively, and no longer use the smaller 10440 size with less capacity. I really prefer using four Lithium Iron Phosphate batteries, LiFePO4 (LiFe, IFR), because of their longevity and safety. I ordered a different brand of 10440 cylindrical LiFePO4 from an online source called Only Batteries, which is located in both the US and Canada. I tested their IFR10440 300mAh 3.2V and found them unacceptable for our use. My Review and testing is found here. This is BAD news! In November of 2023, a myriad of LiFePO4 10440 size battery offers showed up on Amazon. They all use one of the same three photos of the batteries and claim a capacity of 500mAh. Using this specific search term on Amazon and it was discovered that 39 individual offers showed up on the first page of their search on December 4, 2023.

The majority of these offers note "Date First Available" as November 2023, although a few noted a date in August of 2023. IT IS PHYSICALLY AND CHEMICALLY IMPOSSIBLE TO CREATE A 10440 SIZE, 500mAh, LiFePO4 BATTERY! DO NOT PURCHASE ANY OF THESE BATTERIES!

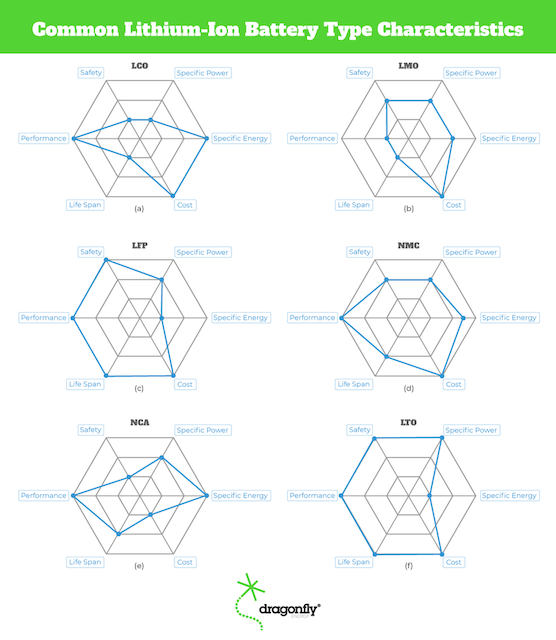

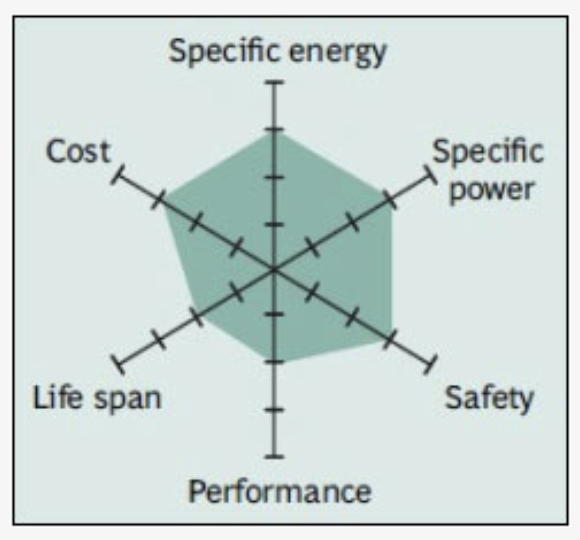

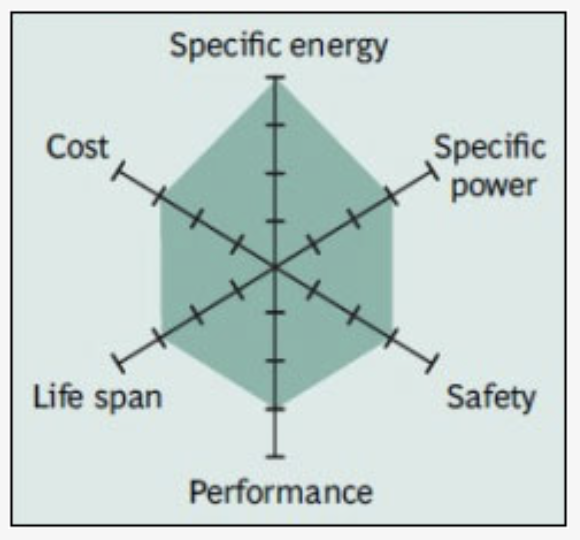

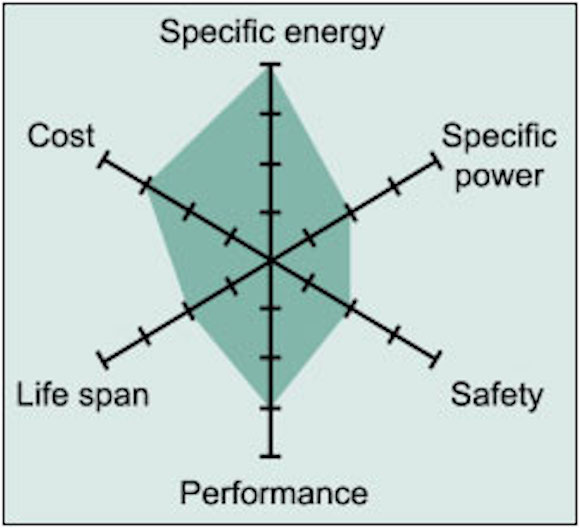

Compare the safety line, at the top left of the spiderweb graphs above. The farther out on the spider graph the line is the greater the noted item is. Descriptions of all 6 of the Lithium-ion chemistries can be found at Battery University. Lithium titanate, Li4Ti5O12 (LTO) can be seen to be one of the safest Lithium-ion battery types. It is quite different from other Lithium-ion battery types as it uses lithium-titanate nanocrystals, instead of carbon, on the surface of its anode. Its nominal voltage is 2.4V. It's not a good choice for Dead rail because its container type is not easily adaptable to modeling and it would take a lot of them to reach the approximately 12V required for HO operation. Lithium Iron Phosphate, LiFePO4, LIF, LiFe, IFR, is also an inherently safe Lithium-ion chemistry. With a nominal voltage of 3.2V or 3.3V it is easy to achieve around 12V for HO use by using 4 batteries in series. There were 10440 (AA size) batteries, but they are no longer readily available. 14500 (AA size) and larger capacities are available from many sources in cylindrical cell format and few places have them in pouch form. Lithium Manganese Oxide, LiMn2O4, LMO, IMR, is not quite as inherently safe as Lithium Iron Phosphate. There were 10440 (AA size) batteries of this chemistry, but they are no longer readily available. 14500 (AA size) and larger capacities are available from many sources in cylindrical cell format. I've not found any pouch batteries with this chemistry. With a nominal voltage of 3.7 or 3.8, 3 of these batteries are used for HO Dead Rail. Lithium Nickel Manganese Cobalt Oxide, LiNiMnCoO2, NMC, INR, while the Spiderweb graph shows it is relatively safe as a Lithium Manganese Oxide, it really is a bit more dangerous than the LMO. It is available in the 10440 (AAA) and up, but I've limited its use to my steam loco tender, and keep a close eye on them. I've not found any pouch batteries with this chemistry. With a nominal voltage of 3.6 or 3.7, 3 of these batteries are used for HO Dead Rail in Dead Rail Applications. Lithium Nickel Cobalt Aluminum Oxide LiNiCoAlO2), NCA, are in what I call the "DANGEROUS" area of the Spiderweb graph and should not be used. Lithium Cobalt Oxide LiCoO2, LCO, ICR is readily available in both cylindrical and pouch formats. They are in what I call the "DANGEROUS" area of the Spiderweb graph and should not be used in Dead Rail applications. I originally ran the Walthers' EMD GP15-1s using three Efest IMR 10440 (AAA size) batteries in a 3S (3 in series) battery pack. (My usage of IMR and INR batteries is discussed later.) The IMRs are relatively safe, especially when compared to LCO batteries, but I knew that Lithium Iron Phosphate batteries were even safer because that is the type of battery that I use in the vast majority of my electric powered RC airplanes. Lithium Iron Phosphate, LiFePO4, Batteries are the safest of the commonly available Lithium-ion batteries. They are also known as LiFe, LFP and IFR. IFR stands for Lithium-Ion, F for the chemical symbol for iron, Fe, and Round, which really means cylindrical. Lithium Iron Phosphate batteries have a nominal voltage of either 3.2V or 3.3V, depending on the manufacturer and the exact chemicals used in the manufacturing process, instead of the nominal 3.6V, 3.7V or 3.8V of other commonly available Lithium-ion batteries. That means that four Lithium Iron Phosphate batteries must be used in series instead of the 3 IMR batteries. That was not a problem as the battery boxes that I was using at that time would hold two batteries each, for a total of four 10440 (AAA size) batteries in series. The original goal was to exchange a bit of Prototypical Run Time, battery capacity in mAh, to use the safest possible batteries. After some prototypical run time testing, it was found that no prototypical run time was given up, as the prototypical run time for these two locomotives, using four IFR batteries, was close to when using 3 IMR 10440 (AAA size) batteries, 55 minutes. To use the 10440 (AAA size) Lithium Iron Phosphate batteries, the same setup for the battery car was used, except that there was no need for a dummy connector, in the shape of an AAA battery. At that time I use Soshine Lithium Iron Phosphate. LiFePO4 that have a nominal voltage of 3.2V and the 4S (4 in series) battery pack had a nominal voltage of 12.8V. 10440 (AAA size) LiFe batteries are no longer readily available. This was absolutely my preferred method. A set of 4 Soshine 10440 size 280mAh Lithium Iron Phosphate batteries was purchased from Ebay at that time. They are not readily available anymore and really aren't needed in any of my Dead Rail applications.

This was the original 10440 LiFe setup. Once I learned that a DGZZI 4 x AA Battery Holder would work in the battery cars, I now use 4 Henreepow 3.2v AA 600mAh Rechargeable Battery 14500 size LiFe batteries.

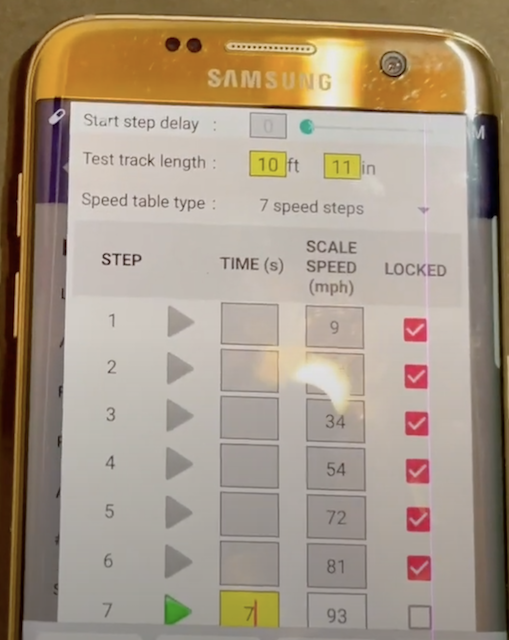

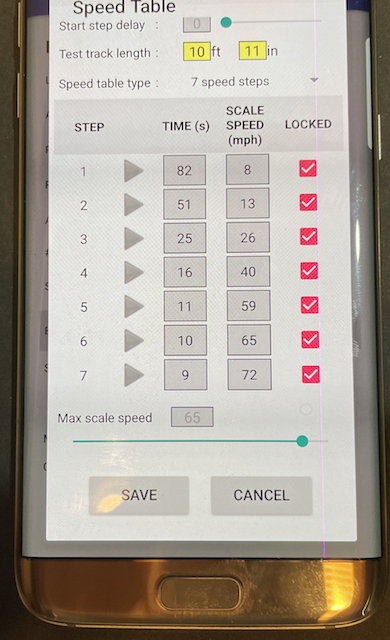

I've now created a battery pack holder to hold the 4S (4 in series) battery pack vertically Originally, the locomotive was configured in the LocoFi™ App for use with a 4S 10440 size 280mAh LiFe battery pack. The step 7 speed was 74 mph and it was set, in the LocoFi™ App, to limit the top speed to 65 mph, the top speed for the GP15-1. The data for this configuration was archived here and opens in a new tab. The locomotive was reconfigured, when the 14500 (AA size) 600mAh Henreepow LiFe batteries were used. Two prototypical run time tests were performed. Both of the test results demonstrated that 55 minutes of prototypical run time was possible. The data has been archived here and opens in a new tab for viewing. After I did this conversion, and completed testing of the IMR and IFR batteries I made some big changes regarding how to evaluate the prototypical run time. When researching batteries for their specifications, I found a lot of differences between various sources. An example of these variations is found here. I now use 4 Lithium Iron Phosphate, LiFePO4 (LiFe, IFR) in my battery cars for the diesels. (See previous Update June 6, 2025.) The 4 in series battery pack for the AlCO

The 3 in series battery pack In February 2024, I discovered that besides using an AA 3 in-line battery box to hold 3 LiMn2O4 (LMO, IMR) or 3 LiNiMnCoO2 (NMC, INR) batteries, a DGZZI 4 x AA Battery Holder can hold 4 LiFePO4 (LiFe, IFR) batteries and physically fit in my trailing battery cars; the 50' boxcar and 53' gondola. A fake or "dummy" battery is used in the 4th compartment of the 4 battery box.

Battery pack in the tender I could have used a trailing battery car with the 2-8-0 Consolidation, but I preferred to have the battery in the tender with the LocoFi™ module and speaker. To fit in the tender, the battery box is a Hxchen 3 x 1.5V AAA Series Connection. It uses the smaller 10440 (AAA) size batteries, and it can be used with all three battery chemistries mentioned. 3 Lithium Iron Phosphates work because the maximum speed of this steam engine is only about 45 mph. The original conversion of the Walthers' EMD GP15-1 CSX to Dead Rail/Battery on Board, used a 300mAh Lithium Polymer pouch (Li-Po) battery. While it was technically successful, it had two MAJOR drawbacks. 1. It used a Li-Po battery pack, which was a very poor battery choice for many reasons, including safety. I do not recommend the use of Li-Po battery packs.

Lithium Cobalt Oxide is also used in most pouch Li-Po batteries. Graphic from Battery University Further research indicated that Lithium Manganese Oxide (LiMn2O4) (LMO, IMR) and Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2) (NMC, INR) cylindrical batteries are inherently safer than Lithium Cobalt Oxide (LCO, ICR). They are readily available in a 10440 (AAA size) and 14500 (AA size). That makes them useful for HO scale conversion to Dead Rail/Battery on Board used with a trailing battery car.

IMR: Lithium-Ion Manganese Round - Lithium Manganese Oxide (LiMn2O4) - LMO "High power but less capacity; safer than Li-cobalt; commonly mixed with NMC to improve performance." INR: Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2) - NMC/INR might be at least equally safe to use with possibly other advantages. Not all INR (Lithium-Ion Nickel Round) are NMC, but the vast majority are. 10440 is a standard way to designate a Lithium-ion cylindrical battery size. It has a diameter of approximately 10mm and length of approximately 44mm. The zero that is furthest to the right indicates that it has a cylindrical form factor. What is most important for us is that this is approximately the size of a 1.5V AAA primary (dry cell) battery. 14500 cylindrical Lithium-ion batteries are approximately 14mm in diameter and 50mm long. That is approximately the same size as a 1.5V AA primary (dry cell) battery. There are a lot of suppliers for IMR and INR 14500 (AA size) batteries but the availability of 10440 (AA size) types of these chemistries has varied greatly over time. By February 2024, the supply of Lithium Manganese Oxide (LMO, IMR) batteries, in the 10440 size, seemed to have disappeared. I discuss them below as an archived reference and because 14500 size LMO batteries are still available. The following is the source that I used to originally purchase the Efest 10440 size, cylindrical batteries.

I used the flat top version. The resultant IMR battery pack consisted of three individual 10440 (AAA) size IMR batteries in series. Each individual battery had a capacity of 350 milliamp hours (mAh) and a nominal voltage of 3.7V with a charge termination voltage of 4.2V. The resultant battery pack was a 3S (three in series) 11.1V 350mAh LMO, or IMR, battery. INR 10440 batteries are available from the supplier that I've been using.

The original EMD GP15-1 conversion using cylindrical batteries used 2 AA battery boxes rewired into a 3 in series configuration (3S). That was totally unnecessary! A Fake or Dummy connector battery could be used instead of modifying the battery boxes. The two AAA battery boxes were modified to make the insertion and removal of each Lithium-Ion IMR 104401 350mAh battery easier. These batteries are no longer available The physical conversion of the battery car is archived here. There is an important thing to note in that archived section and that is "Why 3 IMR or INR batteries are use instead of 4 to create the resultant battery pack." That archived section notes the following about using 3 IMR or INR batteries:

With a full scale EMD GP15-1 having a top speed of 65 mph, it was evident that only a resultant 3S battery pack was necessary. More information about changing from 4 IMR batteries to 3 IMR, or 3 INR, batteries is archived here.

Originally, three Efest IMR 14500 (AA) size batteries were tested using the prototypical run time procedure. The batteries were installed in a 3 in-line AA battery box, as shown in the photo. The results of the testing demonstrated that two hours of prototypical run time was indeed possible. That also indicated that 3 NMC/INR 14500 (AA) size batteries could also be used. Once I learned that a DGZZI 4 x AA Battery Holder could be used with a connector, shaped like a battery, I used the DGZZI battery box with the 3 batteries and the connector. A review of the Efest 14500 testing and its pros and cons compared to using 10440 (AAA) size batteries is also included. The review and testing data have been archived here. Using this set up would also be good for consisting two locomotives or for locomotives whose average amp draw exceeds the 0.25mA of the Walthers' Trainline GP15-1s. It is also useful when prototypical run times in the area of 2 hours are desired. A lot more information on my battery selection is found in my article "Selecting the Battery for the Trailing Battery Car". At first, and because I was trying to keep the price down for those who wished to go Dead Rail, I purchased 2 inexpensive EBL Li-ion Universal Chargers to test them out. They worked okay for the button top Efest IMR Cylindrical 10440 (AAA) Size Batteries. Unfortunately, the chargers minimum fixed charge rate of 0.5A (amps) was really too high for these small 10440 (AA size) 350mAh batteries. Also they could not charge LiFePO4, Lithium Iron Phosphate, (LiFe or IFR) batteries, which are even safer than Lithium Manganese Cobalt, LiMn2O4. The charge rate was also too high for the 14500 (AA size) batteries that I use. I absolutely do not recommend these types of chargers. The information about using these chargers has been archived here. A means to balance charge Lithium-ion batteries is necessary. "No two cells are identical. There are always slight differences in the state of charge, self-discharge rate, capacity, impedance, and temperature characteristics. This is true even if the cells are the same model, same manufacturer, and same production lot. Manufacturers will sort cells by similar voltage to match as close as possible, but there are still slight variations in the individual cells impedance, capacity, and self-discharge rate that can eventually lead to a divergence in voltage over time." That quote is from here. A good lithium-ion battery charger, like mine for RC planes, uses two steps, or stages, to charge each individual cell (AKA battery). First is the constant current stage which then moves to a constant voltage stage where the current decreases to a specified setting. It is called cc/cv charging. A really good explanation of how a Lithium-ion battery charger works is explained in a video titled EEVblog #176 - Lithium Ion/Polymer Battery Charging Tutorial. I did a written summary of the video. This link opens the written summary in a new tab to make that summary available.

Please note all of the previous safety caveats about using Lithium-ion batteries.

The charger must note that it can charge down to at least the 10440 size batteries.

The original discussion, regarding the various types of Lithium based chargers has been archived here.

I now recommend ONLY true multi-chemistry Lithium-ion type chargers.

The SkyRC MC3000 will charge about any rechargeable cylindrical battery chemistry that a hobbyist might use. The charge and discharge current can be adjusted by the user.

It has four totally independent battery slots.

Because it is a true Multi-Chemistry Smart Charger, there is a bit of a learning curve involved.

How much learning?

That depends on your basic knowledge of rechargeable batteries and whether you've programmed some other type of multi-chemistry, programmable charger before.

This charger can send charging data, via Bluetooth, to a FREE App on an Android or iOS smart phone. The data can be viewed in the phone App as well as real time graphs of the data.

This charger can also be linked to a Windows computer via USB cable. The Windows program can control and program the charger, as well as draw the "pretty" graphs that are seen in many battery reviews. It can also save the data to a .csv file.

This charger costs a bit more than other chargers, and also does a lot more.

I have a complete review and tutorial of this charger in PDF format. It can be read online or downloaded.

Using this link will open a new tab where I share my opinion on who this charger is for.

I do not have an ISDT C4 Evo charger

ISDT makes a lot of different sizes and kinds of chargers for hobbyists. Several of the folks that I fly with have ISDT brand chargers, and I have heard of them and have recommended them to others.

DO NOT PURCHASE THE ISDT C4. That is the original version and it can only charge two 10440 size batteries at a time.

It looks like the ISDT C4 Evo can acceptably charge up to four 10440 size or four 14500 size IMR, INR and IFR batteries at one time.

It also has a learning curve.

It does have a color screen, but the data appears to be a bit crowded at times.

There are some YouTube video reviews for the ISDT C4 Evo. This one is from a trusted source for me.

At the end of July 2025, I finally had an ISDT C4 Evo to examine. It belonged to a friend of mine and was on loan. It appeared to be a relatively easy to operate and understand charger, but the first slot on the left side of the charger was dead upon arrival. This can happen to any electrical device. It was returned to Amazon for a replacement.

There is almost no information on a Lithium-ion battery label to help in setting up a charger to charge the battery.

What You Really Need to Know

Two of the major things missing are the do not discharge lower than voltage or the charge termination voltage!

The frequently stated minimum discharge voltages for batteries with a termination voltage of 4.2 volts is 3.0 volts, for LiFePO4 it is 2.5V and for LTO it is 2.0V. Those are very general guidelines and the specific battery's specifications should be checked whenever possible!

Lithium-ion batteries are typically charged at rates between 0.5C and 1C. But what does that mean?

The label states the capacity in either milliamp hours (mAh), for small batteries, or amp hours (Ah), for larger batteries. mAh means milliamps (mA) per hour and Ah means amps (A) per hour. A milliamp is 1/1000 (one thousandth) of an amp.

To set the charger's charge input current flow rate to 1C, use the current part of the mAh or Ah, noted as the mA or A current flow in the rating on the label.

Setting the input current on the charger can be a bit tricky, since most chargers use amps as the charge rate setting.

In most cases, the charge termination voltage is 4.2V except for LiFePO4, which is usually 3.6V and LTO, which is usually 2.75V. Again, those are very general guidelines and the specific battery's specifications should be checked whenever possible!

Examples:

Label info nominal 3.2V, 600mAh, LiFePO4, 1C charge rate, 600mA divided by 1000 equals 0.6 amps. For a 0.5C AKA 1/2C charge rate, the charge rate would be set to 600mA divided by 2 equals 300mA divided by 1000 equals 0.3 amps. The charge termination voltage would set to 3.6V because it is a LiFePO4.

Before making a choice between using 3 IMR or INR batteries or 4 IFR batteries, the user may, or may not, want to review more Lithium-based battery information. I archived more battery information here and it opens in a new tab.

While doing my early conversions, I stated, "One battery box has to be modified so that only three batteries are in the circuit", that is not true. It is much easier not to modify the battery box and just use a dummy AAA size battery that is only a connector The photo shows my original modification to one of the battery boxes, which is no longer necessary when using the dummy AAA size battery that is only a connector. It also shows how the "wings" were removed from the battery box to make battery insertion and removal easier.

Only 3 actual batteries and the dummy AAA size battery, that is only a connector, work just fine and make the modification of the wiring of the battery box unnecessary.

Lithium Iron Phosphate batteries are the safest to use. Because of their lower voltage, four (4) 10440 size IFR batteries are required to be used in the circuit, to run the HO GP15-1 diesels, instead of the three (3) 10440 size used for the IMR or INR set up. That means that neither of the AAA battery boxes needs to be electrically modified, as all four batteries are connected in series.

The photo shows the hook up for four (4) batteries in series. One of the batteries is not in place for the photo as the battery acts as the switch.

The use of IFR batteries requires a true multi-chemistry smart charger, which is more expensive.

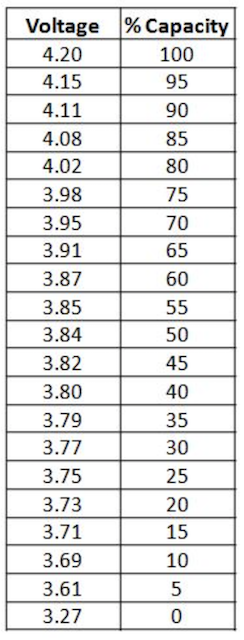

1. Lithium-ion based batteries with a nominal voltage rating of 3.6V or 3.7V are typically fully charged to a charge termination voltage of 4.2V per battery (Some are 4.1V - check the battery specifications) when using an appropriate charger. Even right off the charger, a given battery will not read 4.2V. Within 1 hour to 2 hours, the battery usually stabilizes to about 4.15ish volts per battery. That's its resting, fully charged, stabilized voltage. (LiFePO4 and LTO have quite different specifications and the charging regimen is quite different.) 2. After discharging, the battery's open circuit voltage starts rising and can take anywhere from a an hour or more to stabilize at a new resting voltage. 3. Unlike a power supply, a battery's voltage is continually dropping through its entire use. It is NOT a constant voltage power supply. 4. Lithium-ion batteries have a fully charged maximum voltage, as well as a "don't go below this voltage" or the battery will be ruined. Since the batteries used in both conversions, illustrated here, do not have low voltage protection circuits, the user has to determine when to stop using the battery.

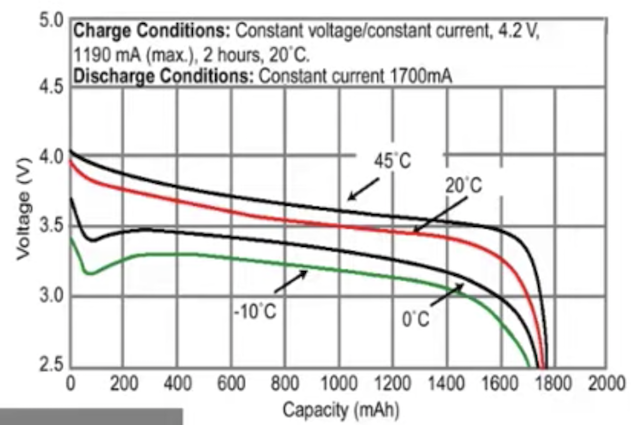

However, measured voltage can only be slightly useful for some types of Lithium based batteries in determining how long a given pack SHOULD be run without dropping to a voltage level that would ruin the battery. Originally there were some graphs here, but they were based on what I now believe to be an incorrect assumption. They have been archived here and will open in a new tab to review. 6. Ambient temperature has an effect on the capacity of Lithium-ion batteries as demonstrated by the following graph.

Source If a layout is indoors, the ambient temperature will usually be close to 20 degrees to 22 degrees C, which is 68 degrees to 72 degrees F. Layouts that are outside, in a basement, or in a garage, or attic, may have ambient temperatures above or below the "normal" range. That is another reason that actual run times will vary. My basement, where the batteries were charged and discharged (run) stays at about 17 degrees C, or about 63 degrees F, pretty much year round.

There are two "knees" associated with Lithium based batteries. There is the discharge knee that I was familiar with, but there is also a state of health knee. That knee happens when the capacity starts to drop a lot and the battery is heading toward dead/unusable quickly.

There is no way to calculate where the discharge knee is, that I could find, besides looking at actual discharge data.

A graph, that I've seen. for the Efest IMR 10440 clearly shows the discharge knee near 3.7V, but the knee for the PKCell ICR 10440 shows the knee in the 3.3V and 3.4V range.

The PK cell has a IR of 0.88 ohms and the IMR 10440 has a resistance of 0.16 ohms, but without the graphs there was no way to know where the different discharge knees are and when the voltage will go over the knee.

| ||||||||||