Because the Derived Run Time Procedure test showed that probably 35 minutes of actual run time was possible, I used a full 30 minutes for the Actual Run Time test. The batteries had been charge the previous day to determine the returned capacity (mAH) after the Derived Run Time Procedure test. There open circuit voltages were; #1 3.353V, #2 3.352V, #3 3.363V and #4 3.344V. After the Actual Run Time Test of 30 minutes of prototypical operations, I could feel no heat from the batteries in my hand. When I got around to measuring their open circuit voltage, they had risen to about 3.255ish volts. The batteries were taken to the flying field for charging. The capacity (mAh) returned was SURPRISING! It was; #1 144mAh, #2 142mAh, #3 141mAh and #4 144mAh. This changes everything!!! When I got home from the flying field, I did a an Actual Run Time test for 40 minutes. Shortly after the 40 minutes of running, for the prototypical run time test, the open circuit voltages measured: #1 3.228V, #2 3.224V, #3 3.221V, and #4 3.223V. Battery #1 was immediately put on the GT500 to charge. Batteries #2, #3 and #4 followed in that order. Capacity Returned

Another Actual Run Time test was completed for 45 minutes of prototypical running on the demo layout. The batteries had been fully charged on Saturday, with the results posted above. Nothing was done with batteries on Sunday. Early Monday morning, the open circuit voltages were measured before the 45 minute run time test; #1 3.398V, #2 3.381V, #3 3.376V and #4 3.369V. The 45 minute prototypical run was completed and the battery charging started immediately with battery #1. Open Circuit Voltage After the 45 Minute Test and the Charge Capacity Returned

Each battery took about 50 minutes to recharge. There was no 50 minute prototypical run made. The labeled capacity of the Soshine IFR battery is 280mAh. Using our RC flying advice of not using more than 80% of the labelled capacity, that would be 224mAh for this battery. The 45 minute prototypical run time was quite close to that 224mAh. The 80% of the labeled capacity rule of thumb is for batteries that are labeled close to correctly. How to determine if they are labeled close to correctly is discussed later. The Derived Run Time Procedure was created so that only a voltmeter/Multi-meter and pair of inexpensive nominal 3.7V, 4.2V termination Lithium-based chargers could be used, thus keeping the initial expense to a minimum. During the LFP testing, it became apparent that using the Derived Run Time Procedure was not working as well as I'd hoped, especially with the Lithium Iron Phosphate batteries. On Friday, August 12, 2022 I ordered a SkyRC MC3000 battery charger from Progressive RC, my main supplier for my RC plane chargers and other electronics. I had viewed the charger's operation on many YouTube videos. I ordered it for a lot of reasons. 1. Because of the way that I had the GT500 setup, I could only charge, or discharge, one battery at a time. That meant a lot of waiting time for batteries to charge, or sometimes discharge using the GT500. The MC3000 can charge or discharge up to 4 cylindrical batteries at one time.

The charger arrived about 2:30 p.m. Monday, August 15, 2022. The Watt hours (Wh) per kilogram (kg) values are found here. Lithium Cobalt Oxide(LiCoO2) - LCO - ICR 150-200Wh/kg nominal 3.6V and some 3.7V

Lithium Manganese Oxide (LiMn2O4) - LMO - IMR 100-150Wh/kg nominal 3.7V

Using an average, rounded weight of 10g

Efest 14500 avg. wt. 19.8g, 19.85g * 100 = 1980 / 1000 = 1.98Wh / nominal 3.7V = 535mAh

Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2) - NMC - INR 150-220Wh/kg nominal 3.6V and some 3.7V Lithium Iron Phosphate(LiFePO4) - LFP - IFR - LiFe 90-120Wh/kg nominal 3.2V and some 3.3V

Using an average, rounded weight of 10g

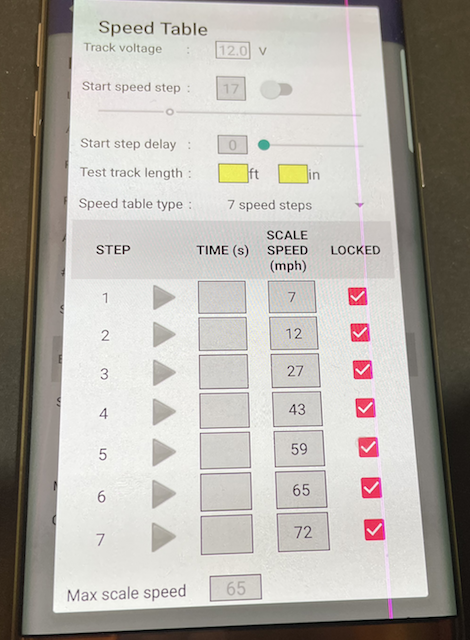

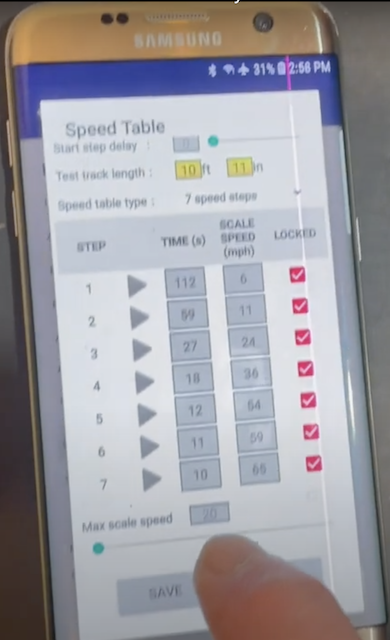

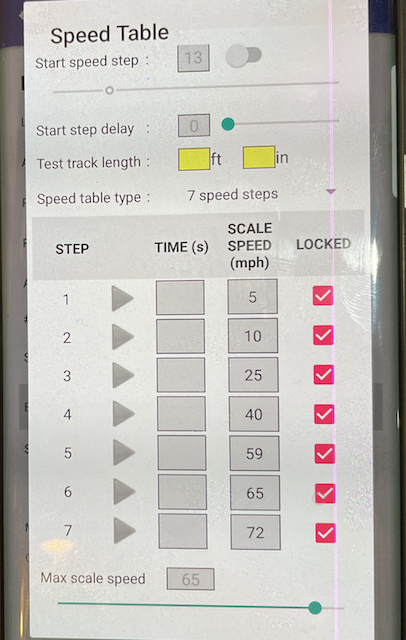

Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO2) - NCA 200-260Wh/kg; 300Wh/kg predictable 3.5V nominal 3.6V Lithium Titanate (Li2TiO3) - LTO 50-80Wh/kg nominal 2.4V Interesting quote from this page, "Figure 15 compares the specific energy of lead-, nickel- and lithium-based systems. While Li-aluminum (NCA) is the clear winner by storing more capacity than other systems, this only applies to specific energy. In terms of specific power and thermal stability, Li-manganese (LMO) and Li-phosphate (LFP) are superior. Li-titanate (LTO) may have low capacity but this chemistry outlives most other batteries in terms of life span and also has the best cold temperature performance. Moving towards the electric powertrain, safety and cycle life will gain dominance over capacity." The reconfiguration for the new 3S 10440 350mAh resultant battery provided a bit of a surprise.  During the original configuration of the CSX, with the 3S Li-Po, the results of Step 7 showed 72 mph for the speed. Remember that speed is determined by the applied voltage.  The Conrail, with its gondola battery car, using a 3S 10440 350mAh resultant battery showed that the Step 7 speed result was 65 mph.  For the reconfigured CSX, with the 10440 3S resultant battery in the boxcar, the Step 7 configuration result was 72 mph, which was the same as when it was powered by the 3S Li-Po. The maximum speed was set to 65 mph, per the full-scale's maximum speed. After recharging the batteries, the Derived Run Time Procedure was performed. The original of this section was archived for reference. To compare this new version to the original, the original can be opened in a new tab. Again, because the Derived Run Time Procedure is no longer used, the data was archived, but it can be opened in a new tab to review it. The bottom line was that 40 minutes of prototypical Actual Run Time was achievable. 02/12/2023: Further testing on my "First HO Train Layout in a Long, Long Time" has shown that 60 minutes is possible using 3 Efest 350mAh IMR cylindrical batteries. |